Crack Inspection

The Inner Crack Inspection module finds bottles with a damaged neck finish. Specifically, bottles with an internal crack just below the neck finish surface are detected. These inner cracks are not visible with the standard neck finish inspection, because these units inspect the surface of the neck. With special optics of module the internal cracks are made visible and the advanced inspection software analyzes the acquired images so that defective bottles are detected and can be removed from the line. • Top Finish, Neck out and Shoulder Crack • Gauging Inspection • Flush Tightness Inspection Heel, Side Body Crack • Line over Finish • Mould Reader and Body Diameter • Thickness of Glass KEYWORDS : Crack inspection, Crack detector, Destructive testing, Radio-graphic testing, Magnetic crack inspection, Crack testing machine, Metal crack testing, Automated crack detection

...more

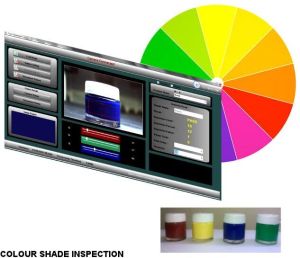

COLOUR SHADE INSPECTION / MATCHING

Determining the color of objects and whether they match specific criteria is important in many manufacturing sectors, including cable manufacturing and assembly. sundaram technologies vision inspection solutions for a wide variety of applications suitable for every line ranging from high speed production line till low speed production line. • colour recognition. • built-in reject mechanism. • reduce the manual work in segregating the colours. • colour extraction. • trend analysis and statistical process control tool. • to improve the quality standard. • optimization, and process improvement. • segregation of colors and arranging them systematically. • development of the real-time color detection. • inspection, process and measurement of image and its pixels. keywords: colour matching test, colour matches, colour matching tool, color coordinator, color combining tool, shades and colors, split color inspection

...more

AUTO PART INSPECTION

Auto part inspection sundaram technologies inspection system enables high speed and automated inspection of all types of components. system can be designed as per customer requirement. Our system detects damages, irregularities, text reading, barcode reading, dimension verification and other abnormalities. This system is mainly used for online quality assurance in automobile industry and electronics industry. various applications - assembly inspection - disk brake injection die inspection - presence absence of any part like pin - roller ball needle inspection in bearing - casting inspection - measurement verifying like linear dimension, angular dimension, circular dimension - to verify any pattern of the automotive part. - bar-code or dpm reading - embossed printed text reading [verification] we can design and customize our system to fit in your application. keywords- camshaft inspection, machine vision inspection systems, surface inspection systems,pattern recognition, automated inspection, camera-based inspection systems, bearing inspection,automobile assembly inspection, barcode dpm inspection, measurement verifying linear dimension,angular dimension, circular dimension, india.

...more

label inspection

Sundaram Technologies product artwork and vision systems deal inspecting of the product packing. This system is highly applicable in food packing and pharmaceutical industries where products are manufactured in bulk quantities. High speed inspection of packing orientation, correct brand of packing,correct size of packing etc is undertaken by Sundaram Technologies vision inspection solutions. We are Zebra Premier Providers and supply spare parts for the entire range including print heads and field installable after-market accessories. Once a product is on a retailer's shelf, labels are a manufacturer's only line of communication with the consumer, so the label needs to be complete and properly located. The label is the business card for each container and contains important information for the consumer on the product in question. KEYWORDS : labels industrial camera, print inspection, label inspection systems, art label template, label verification, machine vision integrator, machine vision online, machine vision, vision systems technology, artwork inspection, camera inspection system, print inspection systems, color machine vision, machine vision products, vision systems automation, label vision systems, industrial vision system

...more

WARE HOUSE MANAGEMENT TECHNOLOGY

WARE HOUSE MANAGEMENT TECHNOLOGY. SUNDARAM TECHNOLOGIES offers warehouse management software packages that can be customized to fit the needs of companies of any size. By combining a warehouse management system with a wireless network, mobile computers, radio frequency identification (RFID) technology, and voice picking applications, We can help fully extend your enterprise to the mobile worker, while increasing operational efficiencies and enhancing your customer service. Additional Sundaram Technologies warehouse software benefits include the ability to: • Automate picking, packing and shipping and minimize the number of moves per order. • Consolidate orders to reduce transportation and shipping costs. • Eliminate annual physical counts. • Reduce expenses on labor and storage by managing tasks and improving processes. • Plan and balance workload and monitor activities with Labor Management integration. • Improve warehouse layout for faster fulfillment and overhead reduction. • Minimize the need for warehouse space with cross-docking and flow-through capabilities. • Integrate material handling equipment (diverts, inductions, pickpack, complex sortation). • User Management and User Access Control.

...more

Fill Level Inspection Services

We fill levels are very important in the production process over-filling a container wastes product, and under-filling can result in recalls and fines. Sundaram technologies inspection systems allow manufacturers to set maximum and minimum fill levels and reject any product that falls outside these. Fill levels can also be adjusted by adding an optional feedback to the filling machine – something which is especially beneficial for liquid foods and • checks colors of individual bars, and check for interchangeability of colors, not just presence of colors. • to confirm that the proper label has been applied • to detect any container with a missing label • to inspect each label for tears, ripples and irregular applications • to measure minimum skew at lap point.

...more

BOTTLE CAP INSPECTION

BOTTLE CAP INSPECTION Cap solutions supply powerful vision inspection systems for 100% inspection of components on production lines in packaging, bottles, closures, print and decoration, food and beverage and other industries. Our camera inspection systems will detect the smallest of defect in your product at very high speed and reject all defective items to ensure that your customer only receives good product. These machine vision inspection systems can be incorporated into new machinery or production lines or retrofitted onto existing equipment. Set up is easy with user friendly self-teaching systems that allow operators to automatically set the system from samples of good components

...more

Batch Code Inspection Services

We are offering batch code inspection services. 5. batch code inspectionocrocv. Ocr means the conversion of written or typed text into a string of characters formatted for machines. Our systems are suitable for print inspection and reading scriptures and symbols of all kinds, even under difficult conditions. The wide variety of signs and marks can be easily and effectively teach. Special features lead to extremely high detection reliability. To receive an exact picture and a re-produce able position of the print, the camera and light module will be installed directly behind the printer. At the moment of inspection the packaging has to be arranged. Of course, beside the exact ocr-reading a visual check-up of the upcoming print can take place (ocv). The print quality of the different areas of the label can be checked with ocv-technique. • printed, lasered, rolled, stamped and embossed ritz fonts and symbols. • expiration dates and other product information.

...more

AUTO PART INSPECTION

12. AUTO PART INSPECTION Sundaram Technologies inspection system enables high speed and automated inspection of all types of flat auto components. Our vision application systems are integrated with the existing high speed line to improve the quality of the inspection process and the standard of the company’s productivity. Sundaram Technologies vision inspection solutions for a wide variety of applications suitable for every line ranging from high speed production line till low speed production line. Our Vision system includes all hardware, software installation, startup, training and documentation. They are adaptable to existing production lines with custom applications and the reliable tracking records. Sundaram Technologies auto parts inspection system enables high speed and automated inspection of all types of flat auto components, like washers, o-rings, nuts, etc. This system is mainly used for online quality assurance in automobile industry and electronics industry.

...more

anti counterfeiting services

Inspection Services

system automation services

Warehouse Management Services

Packaging Solutions

Our applications not only detect presence or absence of product, they also verify orientation, positioning, count, number of multiple products. Once presence absence check is confirmed, the system can go forth and perform other relevant processes like performing vision inspection, rejection, diversion etc NFD detection systems are primarily applicable to the pharmaceutical industry. Our online systems will check NFD- No Fill Detection system and camera system for rejecting defective packs on line. Our Liquid level inspection system inspects the fill level of the liquid. Sundaram’s liquid level inspection systems are your quality control supervisor. They detect empty and damaged bottles and discharge them from your production line. The vision system learns from a sequence of multiple images to obtain the best tolerance settings and compensate for run time variations. Intelligent software significantly reduces the teach time by auto extraction of information. Simple operations through wizard for ease of use of the system during teach-in & productions. Intelligent Software is provided for quick and efficient learning of the sample products. Comprehensive production statistics and fault diagnosis. • Recognition of the shape and position of components • Detection of significant characteristics such as clips, foam rings or holes • Identification of adhesive seals on seams • Recognition of glue volume and position! • Measuring tasks viz: lengths, fold loss. KEYWORDS: Packing inspection, bottling machines, packing of product, packing work, goods packaging inspection, packaging machinery, blister packaging, freight inspection, packing inspection systems, product inspection, quality inspection, packaging inspection, packing machinery, equipment packaging, automatic filling machine, industrial packaging machinery, auto packing machine

...moreBe first to Rate

Rate ThisOpening Hours