Engine Oil Lubricant Filling Machine

Get Price Quote

Medical Gas Pipeline

Get Price Quote

Associated with a diligent professionals and smart packaging facility, we are capable to undertake standard as well as tailored packaging requirements of the clients. Our products are specially produces using premium raw materials to ensure they conform to international management systems of quality.

Best Deals from Filling Line

Rotary Perfume Filler

Get Price Quote

MGL Downstream Gas Pipeline

Get Price Quote

Our firm has been approved by M/s. Mahanagar Gas Limited (MGL) for installation of Downstream Gas pipeline for Commercial & Industrial Applications. We have carried out many Natural Gas installations in recent years. The same installation has been Audited, Certified and Commissioned successfully by the MGL officials.

Automatic Bagging System

Get Price Quote

The machine can be used to pack compounds of PE, PP, ABS, PC, PTA and PA including masterbatch applications. These machines are easy to operate, very flexible, adaptable to a wide product range and easy to maintain. They operate reliably under harsh industrial conditions. In addition, the system provides useful statistical reporting and diagnostic control combined with efficiency monitoring. This feature combined with remote technical assistance guarantees a reliable and efficient operation..

Pharmaceutical Machinery

Get Price Quote

We are a company which is engaged in the supply of pharmaceutical machinery.

Hot & Cold Beverage Vending Machine

Get Price Quote

This Hot & Cold Beverage Vending Machine can offer you Four Hot & Four Cold Option from Four Products. One can get Badam Milk, Coffee, Chocolate & Lemon Tea in Hot & Cold form from this machine. Specifications Machine Dimensions : 465 X 670 X 720MM NO. OF Options : 04 NO. OF Canister : 04 Canister Capacity : 1.2 KG. Water Tank : 3.5 LTR. (Bubble top/online) Weight of machine : 60 KG. Boiling capacity : 1.5 LTR. Chiller tank capacity : 11 LTR. Power consumption : 0.9 Units / Peak output hrs. Power supply : 230 V/AC

Liquid Tetraethylene Pentamine

Get Price Quote

Auger Filler

Get Price Quote

MICROPROCESSOR BASED CONTROL. AUTO / FOOT PEDAL START. COUNTER BASED CONTROL / LOADCELL BASED ALSO AVAILABLE. FILLING CAPACITY AVAILABLE UP TO 50 K.G. ALL CONTACT PARTS IN STAINLESS STEEL 304/316 QUALITY. FILLING SPEED 20-22 JARS PER MINUTE AS PER QUANTITY TO BE FILLED. FLAME PROOF MODEL AVAILABLE. POWER: 230 VOLTS/440 VOLTS, 50 Hz. MATERIAL CAN BE FILLED: POWER, GRANULES, SEMI-LIQUID, GREASE, OR MATERIAL OF HIGH VISCOSITY.

Bottle Filling Equipment

Get Price Quote

Filling capacity: 5ml to 500ml with change parts. Diameter of the bottle that can be handled: 15mm TO 200mm. Height of the bottle that can be handled: 250mm. Height of the bottle that can be handled: 250mm. Fill accuracy: + 1% depending upon the nature of the liquid. The speed of the machines and the conveyor can be varied through a vary frequency AC drive.

Induction Cap Sealing Machine

Get Price Quote

Induction cap sealing machine, The Arshad Fluxosealer™ BREZO P is a manual induction cap sealing machine that is used for laboratory andor low production volumes. This machine consists of a hand held induction sealing head placed over the capped bottle. The Machine starts sealing upon activation by a switch. The sealing time is preset using the Timer on the machine panel. Input Voltage: 230 Volts AC, Single Phase 50 Hertz. 7 Amperes. Sealing Speeds: 4 – 6 bottles per minute. Neck Diameters: 20mm - 83mm. MOC: Mild Steel Powder Coated Enclosure. Max. Power Consumption: 300 Watts. Footprint Dimensions: 400mm x 400mm x 200mm (lxbxh).

Boiler Water Treatment Plant

Get Price Quote

When feedwater containing an inorganic oxygen scavenger is used for attemperation, harmful deposits on superheater tubes andor turbines may result. Because CorTrol OS5601 contributes no inorganic dissolved solid, it is preferable to other inorganic scavengers when feedwater is used for attemperation.

Edible Oil Filling Machine

Get Price Quote

Specifications Non contact electronic sensor to ensure "no bottle no fill" system Mitsubishi make PLC system with T" Touch screen and VFD control for conveyor speed control German measuring chamber for better repeatability of 0.05% Body frame made up of M.S with Powder coating or Stainless steel Applications Edible Oil Lube Oil Lubricant Cooking Oil

Bag Vacuum Packing Machines

Get Price Quote

Semi Automatic Jar Washing Machine

90,000 Per Piece

Tea

Get Price Quote

At Oman Trade, we believe we've hit on the right pulse to be able to offer the kind of variety and breadth of product types we boast of. Built for various sizes, in packs or pet jars, we are capable of mixing and matching and have created several customized products. Whats better? We can execute all of this under a private label. Oman Trade shares a long and mutually beneficial, vibrant relationship with a very reputed tea processor in India who have been in the tea business for decades with presence not just in India but Sri-Lanka as well which automatically exposes us to Ceylonese brands and types of tea as well. Our associate's manufacturing facilities are ISO 22000:2005, HACCP, ISO 9001:2008, GMP and Halal certified. Some of the types of tea we export are Arabian blend, Kesari Masala, Cardamom, Green Tea, Earl Grey and more. In the instant pre-mix format we offer Masala, Cardamom, Saffron, Ginger, Lemongrass and more.

Powder Filling Machine

160,000 Per Piece

Air Headers

Get Price Quote

We are engaged in manufacturing and exporting an extensive range of Air Headers to our valuable clients. Offered in varied sizes, these headers are offered withselector switches, condensing pots, gauge savers and melt bolts. Our range stands on international quality standards and is widely acclaimed for their easy installation, dimensional accuracy, chemical resistance, optimum performance, leakage proof nature and corrosion resistance nature.

Air Headers

Get Price Quote

We are offering air headers. Air headers replaces many unit valve assemblies , which would normally be operating from one source. the air headers are suitable for use with a variety of outlet take-off valves. The inlet-connection can be flange- or screwable. A drain-valve is possible at the manifold exit. The manifolds can be supplied with a bracket u clamp for wall mounting.

Check Weigher Machine

Get Price Quote

A checkweigher is an automatic machine for checking the weight of packaged commodities online in dynamic condition. It is normally found at the offgoing end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Any packs that are outside the tolerance are taken out of line automatically. A checkweigher is a system that weighs items as they pass through a production line, classifies the items by preset weight zones, and ejects or sorts the items based on their classification. Checkweighers weigh 100% of the items on a production line. Typically, an infeed section, scale section, discharge section, rejecter or line divider, and computerized control comprise the physical checkweighing system. Checkweighers and their components vary greatly according to how they are used, the items being weighed, and the environment surrounding them. A checkweigher can weigh in excess of maximum items per minute (depending on product size and accuracy requirements).Checkweighers often incorporate additional checking devices such as metal detectors and X-ray machines to enable other attributes of the pack to be checked and acted upon accordingly. “Simply stated, a checkweigher weighs, classifies, and segregates items by weight.” For high-speed precision scales, a load cell using electromagnetic force restoration(EMFR) is appropriate. This kind of system charges an inductive coil, effectively floating the weigh bed in an electromagnetic field. When the weight is added, the movement of a ferrous material through that coil causes a loss of ElectroMagnetic Force. A precision circuit charges the coil back to its original charge. The amount added to the coil is precisely measured. The voltage produced is filtered and sampled into digital data. That voltage is then passed through a Digital Signal Processor (DSP) filter and ring-buffer to further reduce ambient and digital noise and delivered to a computerized controller.It is usual for a built-in computer to take many weight readings from the transducer over the time that the package is on the weigh bed to ensure an accurate weight reading.Calibration is critical. A lab scale, which usually is in an isolated chamber pressurized with dry nitrogen(pressurized at sea level) can weigh an object within plus or minus 100th of a gram, but ambient air pressure is a factor. This is straightforward when there is no motion, but in motion there is a factor that is not obvious-noise from the motion of a weigh belt, vibration, air-conditioning or refrigeration which can cause drafts. Torque on a load cell causes erratic readings.A dynamic, in-motion checkweigher takes samples, and analyzes them to form an accurate weight over a given time period. In most cases, there is a trigger from an optical(or ultrasonic) device to signal the passing of a package. Once the trigger fires, there is a delay set to allow the package to move to the "sweet spot" (center) of the weigh bed to sample the weight. The weight is sampled for a given duration. If either of these times are wrong, the weight will be wrong. There seems to be no scientific method to predict these timings. Some systems have a "graphing" feature to do this, but it is generally more of an empirical method that works best. A reject conveyor to enable the out-of-tolerance packages to be removed from the normal flow while still moving at the conveyor velocity. The reject mechanism can be one of several types. Among these are a simple pneumatic pusher to push the reject pack sideways from the belt, a diverting arm to sweep the pack sideways and a reject belt that lowers or lifts to divert the pack vertically. A typical checkweigher usually has a bin to collect the out-of-tolerance packs. Tolerance methods There are several tolerance methods: The traditional "minimum weight" system where weights below a specified weight are rejected. Normally the minimum weight is the weight that is printed on the pack or a weight level that exceeds that to allow for weight losses after production such as evaporation of commodities that have a moisture content. The larger wholesale companies have mandated that any product shipped to them have accurate weight checks such that a customer can be confident that they are getting the amount of product for which they paid. These wholesalers charge large fees for inaccurately filled packages. Application considerations Speed and accuracy that can be achieved by a checkweigher is influenced by the following: Pack length Pack weight Line speed required Pack content (solid or liquid) Motor technology Stabilization time of the weight transducer Airflow causing readings in error Vibrations from machinery causing unnecessary rejects Sensitivity to temperature, as the load cells can be temperature sensitive Quality control tape Band with the principles of quality control weight Weighing tape quality control principles Automatic weighing tape Weight control tape Food weight control tape Drug for weight control tape Detergent industry for the quality control tape Weight control tape for chemical industry Weight control tape for the pasta industry Flour weight control tape for the industry Applications In-motion scales are dynamic machines that can be designed to perform thousands of tasks. Some are used as simple caseweighers at the end of the conveyor line to ensure the overall finished package product is within its target weight.An in motion conveyor checkweigher can be used to detect missing pieces of a kit, such as a cell phone package that is missing the manual, or other collateral. Checkweighers are typically used on the incoming conveyor chain, and the output pre-packaging conveyor chain in a poultry processing plant. The bird is weighed when it comes onto the conveyor, then after processing and washing at the end, the network computer can determine whether or not the bird absorbed too much water, which as it is further processed, will be drained, making the bird under its target weight.A high speed conveyor scale can be used to change the pacing, or pitch of the products on the line by speeding, or slowing the product speed to change the distance between packs before reaching a different speed going into a conveyor machine that is boxing multiple packs into a box. Typical Uses of a Checkweighers Check for under and/or overweight filled packages Insure compliance with net contents laws for prepackaged goods Check for missing components in a package including labels, instructions, lids, coupons, or products Verify count by weight by checking for a missing carton, bottle, bag, or can in a case Check package mixes against weight limits to keep the solid to liquid ratio within established standards Reduce product giveaway by using checkweigher totals to determine filler adjustments Classify products into weight grades Insure product compliance with customer, association, or agency specifications Weigh before and after a process to check process performance Fulfill USDA or FDA reporting standards Measure and report production line efficiency

lpg cylinder filling machine

Get Price Quote

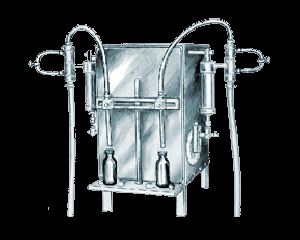

Liquid Filling Machine

Get Price Quote

• Precision and sturdy built Doube Head Machine. • Provided with two syringes. • Most accurate filling system. • Simplified changeovers. • Diving nozzle system for foamy liquids (optional). • 1000 to 2000 containers per hour. • Size: 60 cm. X 45 cm. X Ht. 75 cm. • Weight (approx.): 150 kg. • Electricals: 0.5 H.P. To 2 H.P. in 1 or 3 phase. According to the filling capacity.

Tube Filling Machine

Get Price Quote

Fully Auto. Tube Filling/Sealing/Trimming & Coding Machine (For Plastic & Aluminium Tube)Consists of:One rotating disc with interchangeable tube holding sockets for different sizes of tubesSS Filling Syringe Pumps with Teflon ringsSS Filling Nozzles connected to control of "Tailing" with pneumatic systemNo-Tube, No-Fill Sensor, Diving Filling SystemHot air heating of tubes, pneumatic sealing & batch coding and trimmingOne 20 litres capacity SS hopper for paste / ointment One SS block with non-return valve, volume track with fine adjustment and accuracy of +/ - 0.1 %Filling range : From 3 gms to 100 gms with interchangeable syringe pumps for each colour paste.Filling speed : 35, 40 & 45 tubes per minute for manual feedingOptions Available: Mechanical auto feeding of tubes Speed: 45, 50 & 55 tubes/minute.Triple Colour Filling Machine also available.

Bottle brush

Get Price Quote

This Bottles Cleaning Brush works effortlessly to clean, scrub and leave your cookware and utensils shining like new. Italian designed and engineered, these items are beautiful and easy to use.

Automatic Liquid Filling Machine

Get Price Quote

Tube Filling Machine

Get Price Quote

We are offering tube filling machine. our tube filling machine is precision engineered by the authentic manufacturers, who use only latest technology and machinery. These tube filling machines are exceptional to fill and seal of both plastic and laminate tubes. Being an authorized aluminum tube filling machines suppliers in india, we offer customized solutions with all our products. Further, our range of tube filling machine is effectively used in food products, pharmaceutical and light industries. This tube filling machine range also consists of aluminum and plastic tube filling machines. features there is requirement of only one attendantdetachable tube holder chain reduces both the time for repairs (if any) and maintenance costonly specified quantity is filled in the tube that relates to the filling accuracythe perfect sealing solves the issues of leakage and damageit is the most desirable machine used to fill the laminate and plastic tubesthe tube holders are kept at a particular height for negating any kind of damage to the tube

Medical Gas Pipeline

Get Price Quote

Medical Gas Pipeline, medical humidifier bottle, Medical Oxygen Concentrator

Medical Gas Pipeline

Get Price Quote

Edible Oils, Animal Feeds, Corn, Printed Packaging Box, Sugar, Wheat

Atta

Get Price Quote

We are pioneers of Atta in Mumbai. The speciality of our Atta is that it is grinded in traditional chakkis where the fibre is integrated in the flour there by retaining most of the vitamins, Unlike other flour, which are mill oriented.

Pharmaceutical Machinery

Get Price Quote

Pharmaceutical Machinery, Food Processing Machinery