Pouch Filling Machine

55,000 - 250,000 Per piece

1 Piece (MOQ)

Automatic Loader for Centerless Grinder

150,000 - 400,000 Per piece

1 Piece (MOQ)

Best Deals from Filling Line

Oil Tin Filling Machine

100,000 Per Piece

1 Piece (MOQ)

Turntable

Get Price Quote

Heavy Duty construction AC geared motors with VFD ensures smooth and steady rotation rates Rotation speeds are infinitely variable in both forward and reverse directions . Taper roller bearings ensure a steady weld ground . Encoder mounting facility available for automation needs Options available for hands free operation

Induction Cap Sealing Machine

20,000 Per Piece

Application: Food & Beverage Chemical Industry Agro Chemicals Insecticides/Pesticides Petrochemicals products Bottled water Dairy Products Pharma/Nutraceuticals Edible oils Lubricating oils / coolants Cosmetics & Personal Care Herbal powder / Chyavanprash Features Hand held induction sealers can seal foil caps upto 4 to 6 caps per Minute. Semi-Automatic Induction Sealer Can Seal Upto 8-10 Caps Per Minute Fully Automatic Induction Sealer Can Seal Upto 40-60 Caps Per Minute Advanced Mosfet / IGBT technology circuitry ensures better control of the sealing process. Caps with diameters from 20 mm to 90 mm and 20 mm to 120 mm can be sealed. No tools are required for adjustment or set up. Requires no water, 100 % air cooled, silent and has no discharge. Can seal PET / HDPE / PP / LDPE / PVC / Glass container. Digital timer, which ensures accurate recording of time and optimum sealing.

Semi-Automatic Induction Cap Sealer Machine

Get Price Quote

Eltech S-500,Semi-Automatic Induction Cap Sealer is specifically designed for packagers who require a semi-automatic sealing process with low production volumes. The table top model is compact and ideal for production environments where a bottle conveyor is not practically necessary. Built-in guides ensure operators properly line-up containers for sealing. A digital timer lets the operator know when the sealing process is completed. This model is suitable for batch type production and can be used continuously for 24hrs x 365 days. Ideal for laboratory use, stability testing, R & D facilities, short runs test marketing. Advanced Mosfet / IGBT technology Delivers high efficiency sealing power and long term reliability. Sealing time in 1/10 second increments. Compact in size. Handle provides portability with skid-free non-marring feet for use anywhere. Automatic photoelectric switch under sealing head eliminates the need for finger switches to start sealing cycle. "V" stop centering guide for assurance of bottle being under sealing head. No tools are required for adjustment or set-up. It requires no water and is 100 % air cooled. It is silent and has no discharge. Digital UP/Down timer: Provides precise timing from 0.1 to 9.9 seconds. Can seal PET / HDPE / PP / LDPE / PVC / GLASS containers. User friendly Continuous use, rugged built ensures long serving life Fast and easy set up, no moving parts Light weight design ensure easy mobility Safe, reliable and compact.

Container Filling Machine

Get Price Quote

Optionally Available ➤ Automatic container feeding with turn table or packing conveyor ➤ Jacketed hopper & mixing stirrer ➤ Plugging & capping machine It’s ideally suited for filling of pharmaceuticals ointment, cosmetic, adhesive type resin & hardener, fevicol, cream, shaving cream, paste and other high viscose materials rubber adhesive, chyawanprash etc. Salient Features ➤ Dripless accurate filling. ➤ Filling accuracy ± 1% ➤ Filling range 5gm to 500gm ➤ very low space require ➤ lower maintenance require ➤ speed depending upon volume & viscosity of the product ➤ all the contact parts are 304 / 316 / 316L quality as per your requirement

Semi Automatic Web Sealing Machine

350,000 Per Piece

WATER TREATMENNT PLANTS

Get Price Quote

Complete range of water treatment plants to treat water for Physical, Chemical, Organic and Bacteriological impurities to suit potable, industrial and any other specific needs.Pressure Sand Filter Pressure Sand Filter is the most effective primary treatment of water. Raw water having high suspended solids and turbidity is passed through the layers of graded quartz and the treated water is free from suspended solids and turbidity. Pressure sand filter has varied applications in the process industries and drinking water treatment as pre filter for further chemical treatment of water. Available in Mild Steel and FRP vessels with standard size ranging from 300 mm diameter to 2000 mm diameter and flow rate from 1.5 M3/hr. to 60.0 M3/hr. Also on offer is, custom made filters to treat water with higher flow rates. Activated Carbon Filter Water having abnormal taste, odour and colour is passed through activated carbon where, due to adsorption properties of activated carbon, contaminations related to taste, odour and colour are removed. Activated Carbon Filter finds its applications in the potable water filtration and in the process industries where water is to be pre filtered for further chemical treatment and bacteriological treatment. Standard models are available in Mild Steel and FRP vessels to treat water with flow rates of 1.0 M3/hr to 55.0 M3/hr. Can be custom built for higher water flow rates. Water Softener Raw water having scale forming high hardness is passed through sodium based cation resin where hardness forming Calcium and Magnesium ions are replaced with Sodium ions. Treated water coming out is of commercial zero hardness. Softener are used in most of the process industries where water of zero hardness is required and in cooling towers, boilers etc. Available in FRP and Mild Steel Models for regeneration output of up to 300000 Litres between regeneration. Ultra Violet Sterilizers Water having large number of pathogenic bacteria is passed through ultra violet chamber where exposure to Ultra Violet rays kills bacteria in water without effecting physical and chemical properties of water. Sterilizers are equipped with superior quality UV lamp, quartz jacket, Stainless Steel UV chamber and operation panel for efficient dosage of UV. Reverse Osmosis RO plants as they are commonly called, find their applications from desalination of sea water to making ultrapure water for pharmaceuticals and drinking water. Reverse osmosis use spiral wound semi permeable membranes mounted in high pressure containers. Water is forced through the membranes, where solute is retained o the pressurized side of the membrane and pure solvent is allowed to pass through. Treated water is highly purified. All RO plants on offer are carefully designed and configured to suit the needs of the output water with flow ranging from 100 Litres per hour to 100000 Litres per hour and to raw water TDS up to 45000 ppm.

beverage vending machines

100,000 Per Piece

Water Demineralization Plant

Get Price Quote

The company has emerged amongst the topmost Manufacturers and Suppliers of Water Demineralization Plant. Water Demineralization Plant uses ion exchange process during the processes for removal of dissolved solids or minerals from the water. We employ the latest engineering techniques with high precision while manufacturing Water Demineralization Plant. Water Demineralization Plant, offered by us, finds its application in oil and gas sector, pharmaceutical industry, chemical industry and many more. Additional Information The ion-exchange process involves two stages of demineralization : Removal of cations from the water by the cation exchange process.Removal of anions from water by the anion exchange process.

Water Filtration Plant

Get Price Quote

We are the manufacturers, exporters and supplier of this products.

Filling and Dispensing Pump

360,000 Per Piece

DM Plant

Get Price Quote

Ion exchange technology is used to remove salts (cations and anions) from the water Soluble chemical compounds, when dissolved in water, become ionized; that is their molecules dissociate into positively and negatively charged components called ions. Consider common table salt, sodium chloride. In its solid form, this compound consists of one sodium atom (Na) and one chlorine atom (Cl) tightly coupled together (NaCl). When dissolved in water, however, the compound splits into two ions, Na and Cl. Ion Exchange A process in which Contaminant ions are exchanged from water is called ion exchange. This process occurs in ion exchange resin Initially, resin is loaded with hydrogen (H ) ion for cations and hydroxide (OH-) ion for anions. As water passes through the resin, the contaminant ions in the water displace the loaded ions from the sites on the resin. This is because the resin has a greater affinity for the contaminant ions. Affinity for most resins is based loosely on ionic size and charge

Peristaltic Filling Pump

Get Price Quote

The peristaltic filling principle is the fastest growing in the Pharmaceuticals ,Cosmetics,Chemistry – Biotechnology ,Food and Beverage and various other industries due to established advantages such as sterility, no cross contamination and easy cleaning. The product comes in contact only with the medically approved tubing and filling nozzle. This tabletop peristaltic filling machine provides an accurate and high quality dosing of bottles, tubes, and vials FEATURES No cross contamination Accuracy +/-0.5% 1 ml to 3500 ml Drip-free Change of product in 1 minute Easy Cleaning Easy Cleaning MODELS EASY FILL PP100 MASTER, PP500 MASTER, PP1000 MASTER, PP2500 MASTER SPECIFICATIONS Filling volume:1 ml to 3500 ml (Ex.: 5ml, 25ml, 50ml, 100ml, 150ml, 200ml upto 3500ml) Accuracy:Better than +/-0.5% Human machine interface:Communication with user through Keypad & LCD display Tubes:Silicone tubes with ID 2 mm to 10 mm with wall thickness of 1.5mm. The tubes are approved for pharmaceutical use, according to FDA and USP standards. USES AND APPLICATIONS Pharmaceuticals Food Processing Chemicals Inks & Pigments Cell culture Filtration and separation Pollution control Beverage dispensing Photo Processing and printing Fermentation, Heat treatment Aspiration of tissue culture medium Circulation of cell suspension in fermentation Cosmetic dispensing Harvesting cell media Nutrient supply for cultures Spray coating dispensing Sterilised media dispensing Acid/base dispensing Adhesives for cement Circuit board manufacturing Dispensing glue emulsions Transfer of fuels and lubricants Digital Analytical Instruments Spectrophotometer Variable Angle Ellipsometer Polarimeter Contact Angle Meter Reflectometer Laser Raman Spectro Photometer Refractometers Hand-Held Refractometer Digital Pocket Refractometer Digital Laboratory Refractometer Peristaltic Pump Peristaltic Filling Pump Peristaltic Pump Tubings Telescopic Conveyor Industrial Belts Vision Inspection Systems for Plastic Sheet Headspace/Package gas analyzer Model 200 Model 901 Model 902D Model 902P Model 905P Model 905V Model 906 Model 907 Portable XRF Analyzer TrueX-Hand-held-Gold-Analyzer Truex Handheld alloy Analyzer Cooking Oil Tester Beverage Gas Monitoring System Bev-Alert System Acetaldehyde, Methanol, & Benzene in CO2 Applications Total Sulfur in CO2 Applications Total Hydrocarbon Analyzer Liquid Crystal Testing Instruments Hot & Cold Stage Liquid Crystal Cells & Cell Holder Automatic Liquid Crystal Tester Online Density Meter Torque Tester Digital Torque Tester Automated Torque Tester Dynamometeric Torque Bottle Leak Tester Secure Seal Tester (ECO) Crown Cap Leak Tester Dimensional Measurement Accurate Magnetic Thickness Gauge PET Bottle Perpendicularity Gauge Crown Cap Angle Gauge Base Clearance Gauge

Programmable Filling and Dispensing Pump

Get Price Quote

These pumps are designed for accurate repetitive dispensing or general fluid transfer. Models are available for bench top manual dispensing to integrated filling lines.Whether your application requires integration of a standard dispenser into your systems or a custom designed pump. We have the experience, technical knowhow & dedicated engineering staff to design a dispenser to meet your specific need. FEATURES • Dial a flowrate from 0.8 ml/min to 8000 ml/min. • Programmable dispensing Volume. • Programmable RPM to avoid Splashing & Frothing. • Pump has got programmable Suck Back Facility which ensures drip less fill at dose ends. • Calibration by weight / volume / time. • Step mode specially designed for pelletization machines. • Splash proof membrane keyboard for manual speed control. • TTL outputs & inputs for integrations with other equipment.

JumboFIBCBag Unloading System

Get Price Quote

Automatic Goli Soda Filling Machine

30,500 Per Piece

1 Piece (MOQ)

Chilling Plant

Get Price Quote

We are offering chilling plant, cooling tower. 1 ancillary equipments. ** for value addition to your end products & to increase productivity, we can offer various ancillary equipments which are helpful in production process. ** air compressor. ** cooling tower. ** water chilling plant. ** scrap grinder. colour mixer. ** hot air oven. ** water pumps. ** industrial pumps. ** corona treater. capacity of each equipment is worked out based on output capacity of main machines & plants.

Automatic Case Packing Machine

Get Price Quote

The Loynds Double Twist Wrapper is of a modern design which makes for easy cleaning and maintenance. The machine has a wrapping speed of up to 500 per minute and has a fully self-contained lubrication system. The film length is changeable by PLC.

Water Demineralization Plant

Get Price Quote

Water Demineralization Plant uses the demineralization process by which the mineral slats are removed from water using the ion exchange process. Synthetic, cation resin exchanges hydrogen ions (H+) for positive ions, and anion resin exchanges hydroxide ions (OH-) for negative ions. Water quality from demineralization systems is typically around 1 part per million (ppm). We offer single and separate-bed Water Demineralization Plant for improved water quality. Using the ion exchange process in which calcium and magnesium ions are exchanged with sodium ions, the water softeners eliminate scaling and residues on industrial equipment and boilers. We offer a wide range of Water Demineralization Plant for industrial and commercial use.

Distemper

800 Per Pack

25 Pack(s) (MOQ)

Distemper

Get Price Quote

Edible Oils, Specialty Chemical, Stearic Acid, Palm Oil

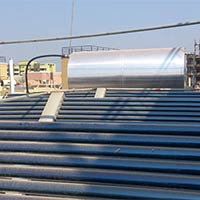

Solar Water Heating Systems

Get Price Quote

100 Piece(s) (MOQ)

Cira energies provide complete solution in solar based water heating system be it in flat plate collector (fpc) type or evacuated tube collector (etc) type, heat pipe (hp). The system’s provide 24 hrs hot water at desired temperature. cira energies provide all type system be it thermosyphon, forced circulation or pressurized force circulation, open loop and close loop type systems.

Drum Cap Sealing Machine

Get Price Quote

automatic inkjet cartridge refilling machine vacuum filling machine

Get Price Quote

automatic inkjet cartridge refilling machine vacuum filling machine

DM Plant

Get Price Quote

We are offering dm plants are available in a wide range with maximum flow rates upto 25m3 hr. Two bed dm plant comprise of two mild steel rubber-lined frp pressure vessels filled with strong acidic cation exchange resin and strongly basic anion exchange resin. They are available in a range of diameters. The modular construction permits flexibility in the selection of cation and anion units to cater to different types of raw water. Degasser modules for the range of ca units are also available. These are useful for raw water containing a significant amount of alkalinity. Treated water of conductivity less than 10 microsiemencm with ph of 7.5 to 8.5 is achieved at two bed dm plant outlet.

Aseptic Filler

Get Price Quote

Aseptic Filler, lanyard, Satin Top

Industrial Water Chilling Plant

450,000 Per Piece

1 Piece (MOQ)

Water Purification Plant

Get Price Quote