Small Bag Filling System

Get Price Quote

Water Chilling Plant

Get Price Quote

Our Water Chilling Plants are energy efficient and environment friendly. They are in high demand with our clients. The equipment is used for removing heat from water. Highly reliable, our Water Chilling Plants are used in various commercial, industrial & institutional establishments. These Water Chilling Plants have a sturdy construction and require minimal maintenance. The Water Chilling Plants are reliable and deliver consistent performance. Our Water Chilling Plants are available to clients at economical prices. Usage : Air conditioning systems to transfer sensible & latent heat which results in cooling the air stream.Industries where these plants are required for controlled cooling of products, mechanisms and various types of factory machinery.To cool high-heat and specialized items such as MRI machines and lasers. Additional Usage In : Analytical equipmentChemical processingCompressed air and gas coolingDie-castingFood and beverage processingInjection and blow moldingMachine toolingMetal working cutting oilsPharmaceutical formulationPower generation stationsPower suppliesSemiconductorsVacuum systemsWelding equipmentX-ray diffraction

Best Deals from Filling Machine

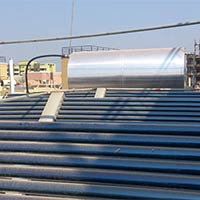

Solar Water Heating Systems

Get Price Quote

100 Piece(s) (MOQ)

Cira energies provide complete solution in solar based water heating system be it in flat plate collector (fpc) type or evacuated tube collector (etc) type, heat pipe (hp). The system’s provide 24 hrs hot water at desired temperature. cira energies provide all type system be it thermosyphon, forced circulation or pressurized force circulation, open loop and close loop type systems.

Semi Automatic Liquid Syrup Filling Machine

26,000 Per Piece

1 Piece (MOQ)

Pouch Filling Machine

55,000 - 250,000 Per piece

1 Piece (MOQ)

Distemper

800 Per Pack

25 Pack(s) (MOQ)

Induction Cap Sealing Machine

20,000 Per Piece

Application: Food & Beverage Chemical Industry Agro Chemicals Insecticides/Pesticides Petrochemicals products Bottled water Dairy Products Pharma/Nutraceuticals Edible oils Lubricating oils / coolants Cosmetics & Personal Care Herbal powder / Chyavanprash Features Hand held induction sealers can seal foil caps upto 4 to 6 caps per Minute. Semi-Automatic Induction Sealer Can Seal Upto 8-10 Caps Per Minute Fully Automatic Induction Sealer Can Seal Upto 40-60 Caps Per Minute Advanced Mosfet / IGBT technology circuitry ensures better control of the sealing process. Caps with diameters from 20 mm to 90 mm and 20 mm to 120 mm can be sealed. No tools are required for adjustment or set up. Requires no water, 100 % air cooled, silent and has no discharge. Can seal PET / HDPE / PP / LDPE / PVC / Glass container. Digital timer, which ensures accurate recording of time and optimum sealing.

Semi Automatic Bottle Filling Machine

Get Price Quote

The Semi Automatic Bottle Cleaning machine works on compressed air and suction blower arrangement. The bottles are placed in inverted position manually on the nozzle. As soon as the bottle is placed, the solenoid valve actuates and filtered compressed air is sprayed inside the bottle and the suction blower sucks the foreign particle if any. After cleaning, the bottles are transferred manually to the filling machine. It gives an output of 20 to 40 bottles per minute depending on operator skill.

Industrial Water Treatment Plants

Get Price Quote

We are counted as one of the illustrious water treatment plant manufacturers from india. We present drinking water treatment plant that is utilized in diverse industries for varied applications. We fabricate industrial water treatment plants from high quality raw materials.

Ro Water Purifier Plant

1,200,000 Per Set

1 Set(s) (MOQ)

We having experience of over a decade, we have goal of high quality service worldwide. We are unique with combination of Knowledge & Experience in Water Treatment. We provide comprehensive spectrum of technologies for producing all grades of Water required in Testing Lab, R&D, Production & Drinking.

Automatic Loader for Centerless Grinder

150,000 - 400,000 Per piece

1 Piece (MOQ)

Industrial Ro Plant

95,000 Per Set

1 Set(s) (MOQ)

Drum Filling System

Get Price Quote

1 Set(s) (MOQ)

Drum Filling System

Get Price Quote

Edible Oils, Specialty Chemical, Castor Oil Cosmetics, Jelly Filled Cable

Turntable

Get Price Quote

Heavy Duty construction AC geared motors with VFD ensures smooth and steady rotation rates Rotation speeds are infinitely variable in both forward and reverse directions . Taper roller bearings ensure a steady weld ground . Encoder mounting facility available for automation needs Options available for hands free operation

Automatic Case Packing Machine

Get Price Quote

The Loynds Double Twist Wrapper is of a modern design which makes for easy cleaning and maintenance. The machine has a wrapping speed of up to 500 per minute and has a fully self-contained lubrication system. The film length is changeable by PLC.

Dm Water Plant

20,000 Per Piece

Tea

499 - 1,999 Per Rs

Tea, Whole Spices, Grounded Spices, Darjeeling Tea

Water Treatment Plant

20,000 - 200,000 Per Unit

1 pcd (MOQ)

Water treatment plant, mineral water project, softner, dm plant, carbon filter, ss water pump, pet bottle machine.

Oil Tin Filling Machine

100,000 Per Piece

1 Piece (MOQ)

Aseptic Brick Carton filling Machine

Get Price Quote

Aseptic brick shaped carton filling machine suitable for juice,uht milk,cream, milk products,ghee ,tomato sauce filling.

Tea

220 Per Kilogram

100 Kilogram (MOQ)

Auger Filling Machine

Get Price Quote

We offer precision engineered Auger Series Powder Filling Machine which is a highly demanded machine used for filling all kinds of powder into bottles, pouches, etc. With a filling range of 50-1000 gm, this portable machine is known to deliver an accuracy of /- 1 gm.The specifications and features of our machine are: 660 x 650 x 1800mm height frame size 230VAC single phase power supply Stainless Steel contact parts 15kg hopper size Weighmetric filling equipped with digital Weighing machine Foot switching-one touch start Clutch brake driving system 24 V DC stirrer motor for stirring powder in the hopper Increased efficiency High output Light weight This machine is an easy to handle machine in which the powder to be filled is placed under the nozzle and once the machine presets the amount of water and displays the actual amount of powder on the weighing machine. Ensuring accuracy in powder filled, the container is then removed and the process is repeated till required.

Pet Blowing Machine

Get Price Quote

We offer PET Stretch Blowing Machine from Famous Brand 'Global PET'. The 'Global PET' Machines are two stage, linear type blow moulding machines with simple and unique design. It uses combination of Pneumatic and Hydraulic versions for better and fast quality output. Robustness and long lasting service of component are protected by mechanical and electrical safety systems. Constant quality of bottle production is based on the precision repetition of heater control and stretch motions. Preform carries and blow cells are easily changeable allowing product versatility. The main function of start up operation are combined on the machine integrated LCD Control Panel. Trouble Storage can be accomplished by accessing the LCD Display Screen, Programmed to assist the Operator in evaluating machine conditions. Multi Security devices insure the safety of operators and protect the machine.

Water Demineralization Plant

Get Price Quote

The company has emerged amongst the topmost Manufacturers and Suppliers of Water Demineralization Plant. Water Demineralization Plant uses ion exchange process during the processes for removal of dissolved solids or minerals from the water. We employ the latest engineering techniques with high precision while manufacturing Water Demineralization Plant. Water Demineralization Plant, offered by us, finds its application in oil and gas sector, pharmaceutical industry, chemical industry and many more. Additional Information The ion-exchange process involves two stages of demineralization : Removal of cations from the water by the cation exchange process.Removal of anions from water by the anion exchange process.

Reverse Osmosis Water Treatment Plant

Get Price Quote

Technical specification reverse osmosis system feed flow rate : 2500lhr (minimum) permeate flow rate : 1000 lhr recovery : 40 % high pressure pump : cri 100 mwc head or equal ant pressure tube : frp ro membrane : csm korean make 01 no skid moc : ms powdered coated pre filter set with 5 micron cartridge 20 inches long ro control panel : provided ro instruments : flow meters, pressure gauges. Ro piping size & moc : 1 inches – cpvc.

adhesive filling machine

Get Price Quote

Adhesive filling machine PLC controlled Machine with colour Touch Screen, Easy change over from one size to another. Can fill creams of various viscosity.

Sewage Treatment Plant

Get Price Quote

We are offering sewage treatment plant. Altido corporation is the leading water treatment and process improvement company, delivering significant environmental, social and economic performance benefits to a variety of residential, industrial and institutional customers. Our programs and services are used in water treatment applications.

Super Glue Filling Machine

Get Price Quote

SEWAGE WASTE WATER TREATMENT

Get Price Quote

This is a conventional process to treat the hospital wastewater. In this process the wastewater is treated in open tank called aeration tank and air is supplied either through fixed / floating surface aerator or air blower to provide oxygen for the aerobic microbes. Around 12-15 hour hydraulic retention time is provided for the treatment of wastewater. The microorganisms utilize the oxygen in the air and convert the organic matter into stabilized, low-energy compounds such as NO3, SO4, and CO3 and synthesize new bacterial cells. The overflow carried to the adjacent clarification system contains active microbes and is required to be recycled back to aeration tank to maintain specified critical performance rating parameter like MLSS and F/M ratio. Advantages BOD5 removal efficiency > 90%. User friendly. Require less skilled labour for operation and maintenance (O &M). Oxidation and nitrification achieved without chemicals. Maximum removal of suspended solids up to 97%. Most widely used wastewater treatment process because of non-availability of any othertechnology. Moderate land area. Ability to handle peak load and dilute toxic substances.