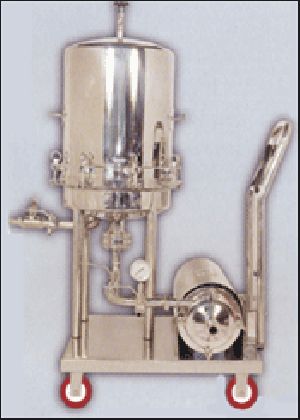

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press that we offer is precisely manufactured keeping in mind the set industry standards. Our Zero Hold Up Filter Press is subjected to stringent quality tests prior to its final dispatch. We are counted among the top Manufacturers and Suppliers of Zero Hold Up Filter Press. WE are efficient enough to process retail as well as bulk orders for Zero Hold Up Filter Press even at short notice period. Details : Manufactured in Ss-304 / 55-3161 55-3161 Quality, Argon Arc Welded and Mirror Polished. Ss Jacket Can Be Provided for Hot Filtration. It is Generally Used to Obtain Crystal Clear Filtration By Filtration By Filtering Particles Up to 1 Micron Size. It Can Be Provided with Different Types of Pumps I.e. Gear Lobe Centrifugal Pump, Depending On the Viscosity of Liquid and Output, Which Can also Be Used for Liquid Transfer. T.E.F.C. Flame Proof Motors Can Be Provided. Provided with Pressure Gauge, Safety Valve, Bypass System, Sampler, Air Vent & Drain System. Can Be Manufactured as per Customer Design Requirement. Cake Formed Between the Plates Can Be Obtained if Required. and Also, It (cake) Can Be Dried Either By Compressed Air or By Inert Gas, Steam. Complete Unit is Mounted On Ss Trolley & Fitted with Ss Bracket, Pu. Bond Castor Wheels for Easy Movement. Scavenger Plate Arrangement to Remove all the Liquid.

Filter Press

Get Price Quote

The unfiltered liquid is fed into the filter under positive pressure, where liquid travels in downwards direction and finds its way through opening on sides of the Filter Plates. As the liquid pressure increases, the Filter media holds the foreign particles and allows only clear filtrate to pass through the central channel formed by interlocking pressure cups to the outlet. Filtration is continued until the cake holding capacity of the unit is reached or until the filtrate rate becomes too slow owing to cake resistance. Innovative Features : • Horizontal Plate Filter Press is enclosed construction, preventing evaporation, oxidation, leakage and fumes escaping from product. • Filter plates are available in two sizes. Deep plate for large percentage of cake holding capacity and Shallow plate for small percentage of cake holding capacity. • The horizontal filter plate and even thickness of cake, prevents the cake dropping as well as cracking, thus assuring better filtrate quality. • The Filtration area and cake holding capacity can be increased or decreased according to requirement.

Best Deals from Filter Press

Chemical Filter Press

Get Price Quote

Avail well designed Chemical Filter Press from G. P. Filtech Engineers. We are acknowledged among the leading Manufacturers and Suppliers of Chemical Filter Press. These Chemical Filter Presses are manufactured as per the international standards. The best raw material is used to manufacture these Chemical Filter Presses. Sizes Available 250mm x 250mm355mm x 355mm500mm x 500mm610mm x 610mm800mm x 800mm915mm x 915mm1000mm x 1000mm1200mm x 1200mm

Zero Hold Up Filter Press

Get Price Quote

REVERSE FLOW ZERO HOLD UP TYPE : Here the direction of flow of liquid is exactly opposite to the flow in standard filter i.e. the impure liquid to be filtered enters the filter from the bottom into the center channel & goes to the top of each plate. The clear filtrate flows out from openings on side of plates to the shell & then to the outlet. This flow ensure almost 100% filtration of the liquid which is not so with the standard flow type.

Membrane Filter Holder

Get Price Quote

• Model Available : 142mm & 293mm Dia. • M.O.C.S.S 304 / 316 / 316L. • It is provided with Center and Non Sticky S.S. Perforated Sieve, Silicon ‘O’ Ring Detachable S.S. Stand and with Inlet Outlet Connection etc. • Option : Bubble Test Arrangement.

Filter Press

Get Price Quote

The clear filtrate flows out from openings on side of plates to the shell & then to the outlet. This flow ensure almost 100% filtration of the liquid which is not so with the standard flow type

Frame Type Filter Press

Get Price Quote

We are offering frame type filter press. Indo german plate & frame type filter press is designed for filteration and clarification of pharmaceuticals, chemicals, food and bewerage industries.

Filter Press Machine

150,000 Per Piece

1 Piece (MOQ)

Sparkler Filter Press

Get Price Quote

We among the most trusted firms, indulge in manufacturing, supplying and exporting Sparkler Filter Press. Used in several industries like automobile, automotive and textile, these products are made using quality material and latest technology. Our Sparkler Filter Press is also thoroughly checked by expert quality controllers on various parameters to ensure flawlessness. We further conduct regular researches for improvising these products. Working :The liquid is directed with the help of pumps through the centre channel of the cartridge from the bottom of the body. Suspended particles get retained on the fitter medium resting on the filter plates and the clear filtrate emerges from the side holes of the plates inside the tank and flows out from the bottom outlet. The filter tank does not come into contact with the liquids and hence remains clean. The cake filtrates and solids remain completely inside the fully closed filter plate cartridge. Complete recovery of the filtrate is possible by passing of air or an inert gas through the bottom inlet to dry the cakes and get a clean empty tank. Features: • Enclosed construction.• Cake holding capacity.• High production rate. Further Details : • Available in variety of plate size options.• Comes with horizontal filter plate.• Deliver optimum filtrate quality.• Enclosed construction.• Has large cake holding capacity. SALIENT FEATURES:• Maintenance can be easily carried out just by lifting the dome i.e., without lifting the cartridge.• Quick and easy removal of filter plate cartridge for cleaning of cake.• Filtrate is obtained without scavenging agents.• Liquid does not remain between the tank or the cartridge.• Possibility of high working pressure.• Uniform distribution of cake and filtrate.

Membrane Filter Holder

Get Price Quote

It is made out of ss 316 L quality for filteration of sterile solutions. Complete with two silicon ‘O’ rings and support screen with non-sticking mirror polished bolts and wing nuts An air valve is also provided to remove inside air initially. Complete unit rests on suitable legs.It is available in 142mm & 293mm dia sizes SS 316 L Quality Membrane Filter Holder (GMP):- ss 316 L quality for filteration of sterile solutions. Complete with two silicon ‘O’ rings and support screen with non-sticking mirror polished bolts and wing nuts An air valve is also provided to remove inside air initially and available in 142mm & 293mm dia sizes

Horizontal Plate Filter Press

Get Price Quote

Liquid is pumped through the central channel of the cartridge from the bottom of the body. Suspended particles are retained on the filter media resting on the filter plate. Clean filtrate emerges out from the peripheral holes of the plate, into the tank and comes out from the bottom outlet. Filter tank wall does not come in contact with the un-filtered liquid, hence remains clean.

Filter Press

Get Price Quote

Filters Pressused for filtering process in pharmaceuticals, coconut processing plants, milk dairies, distilleries, breweries etc. We supply a wide range of Filters and transfer pumps according to desired capacity that are made using high quality stainless steel. CGMP Zero Hold-Up / Sparkler Type Filter Press consist of Stainless Steel Shell & Top cover using bolts to give pressure tight enclosure. The filter cartridge assembly inside the shell consists of several horizontally arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley. SALIENT FEATURES : • Available model 8", 14" , 18", 24" & 33". •Total access for fast cartridge removal and cleaning filter press machine • Centrifugal / Gear / Lobe pumps can be offered, which can also be used for liquid transfer • MOC SS 304/316/316L. • Complete filtration of the batch without any hold up due to reverse flow of liquid, making it cost efficient and time saving • In compliance with CGMP •Pressure gauge, safety valve & air vent provided to ensure safe operation

Zero Hold Up Filter Press

Get Price Quote

Filter Press

Get Price Quote

Filter Press

Get Price Quote

The filter press is a solid liquid separation device using the principle of pressure feeding. It includes a series of filter plates and frames or recessed plates which are arranged alternately. The filter medium is provided in between the plates. A feeding pump is utilized to force the liquid through the medium leaving the solid trapped inside.