Filter Press Machine

150,000 Per Piece

1 Piece (MOQ)

Purge Filter

Get Price Quote

Micro Meter Filter Used when sampling pressurized air and gasses and sample is required to be captured and not allowed back into the atmosphere. Purge Filter Assembly: 0.1 CFM Flow Rate Purge Filter Assembly: 1.0 CFM Flow Rate Purge Filter Assembly: 50 LPM Flow Rate Purge Filter Assembly: 100 LPM Flow Rate

Best Deals from Filters

Filter Pump

Get Price Quote

Filter pumps have a crucial role in reducing the gold loss in the various stages of Jewellery Manufacture. During the various processes in cleaning of castings and and final pieces, minute grains of gold gets removed from it. These precious metals can be retained by filtering the drain water from each process, along with the use of settling tanks. Even the minute quantities can be saved from wastage. Features:-► Outlet located on filter chamber base.► Vent valve.► Fast-locking by PP Ring.► Switch, cable and plug included with pump motor.► Available models in Manual and Automatic working► Automatic model consist of float sensor to regulate flow automatically

Capacitor Replacement

Get Price Quote

We Aim to Provide Genuine and High Quality Discreet and Passive Components, Manufactured By Leading Brands in the Industry Produced as Them as per the International Standards. We Offer a Complete Range Which Includes Diodes, Transistors, Fet’s, Igbt’s, Resistors, Capacitors, Passive Networks, Etc.

Bacterial Filter

Get Price Quote

1000 Piece (MOQ)

Air Filters

Get Price Quote

We are manufactureres of pneumatic air filters.

Leaf Filter

Get Price Quote

Leaf Filter is designed from Stainless Steel Coarse mesh acting a main support & Hollander Mesh for filtering. Meshes are held together in a tubular leak proof frame by help Stainless Steel frame. Basic used in Chemical & Oil Industries.

Glass Vacuum Filtration Unit

5,500 Per Piece

1 Piece (MOQ)

High Pressure Gas Filter

Get Price Quote

We are offering high pressure gas filter airmatic high pressure series - hpf service : compressed air & gases sizes: 6 mm to 15 mm (g 14", g38" & g12") flow: up to 60 scfm @ 40 kg cmâ²g airblast circuit breakers, oxygen filtration for breathing gas mixture, high pressure blow moulding of plastics, gas filtration for diving bells, starting air for diesel engines, filtration of natural gas, high pressure breathing air. Fertilizer, chemicals, petrochemicals, textile machines, machine tools, pneumatics, refineries.

Membrane Syringe Filters

Get Price Quote

Sundaram Cartridge Drawing Paper - A/3 - 20 Sheets (DR-10)

2,900 Per Carton

1 Carton (MOQ)

Rainwater Harvesting Filter

35,000 Per Piece

Basket Filter

100,000 Per Piece

1 Piece(s) (MOQ)

Side Stream Filters for Cooling Towers

500,000 - 700,000,000 Per Cubic Meter

1 Set(s) (MOQ)

PLASMA FILTER

7,000 Per Piece

1 piece (MOQ)

wire cloth filter

Get Price Quote

We are manufacturer of wire cloth or Wire jali by using stainless steel which has very wide application area..

sparkler filters

Get Price Quote

Principle of Operation Liquid is pumped through the central channel of the cartridge from the bottom of the body. Suspended particles are retained on the filter media resting on the filter plate. Clean filtrate emerges out from the peripheral holes of the plate, into the tank and comes out from the bottom outlet. Filter tank wall does not come in contact with the un-filtered liquid, hence remains clean. Feature of Reverse Flow Model Zero Hold Up of filtrate with out scavenging operation. Tank does not come in contact with unfiltered liquid, hence remains clean. Fast & easy removal of filter plate cartridge due to top dome design. Hence easy removal of cake.Uniform filter cake & aid distribution. Higher working pressure possible. Horizontal Plate Sparkler Filters The horizontal sparkler type filter is the most versatile filtration system for solid – liquid separation. It can also be used apart from filtration, with the help of filter aids for giving a sparkling effect to the liquids filtered. The filters are most suited for the filtration of products for the pharmaceutical, chemical, distillery, beverage, ink, oil and other allied industries. It is available in different output capacities with a variety of pumps to suit individual requirements. Horizontal Plate Sparkler Filters:- horizontal sparkler type filter is the most versatile filtration system for solid – liquid separation and available in different output capacities. Horizontal Plate Sparkler Filters Construction The filters are made out of Stainless steel in S.S. 304, 316 & 316 L qualities. The cartridge assembly consists of a number of disc type filter plates with perforated support screen, filter media and interlocking cups placed one on top of the other and supported at the bottom by a cartridge plate. The entire assembly is held together with the help of side tie rods which are of ‘T’ type construction for longer life. The filter together with the pump and interconnecting piping is mounted on a sturdy base cladded with S.S. sheets and provided with castors for movability. The filter can also be supplied without pump, where external positive pressure is available. Operation The liquid to be filtered is passed into the vessel by means of the pump or other external means. The liquid then passes through the top of the filter plates from the holes provided at the side of the plate and onto the filter media. The liquid flows simultaneously and individually through all the member plates. Hence the output of the filter depends on the diameter and the number of plates. The filter media then retains the impurities in the liquid and the filtered liquid passes through the central channel to the outlet at the bottom. The filters are optionally available with steam jacket for filtration of difficult liquids that solidifies at lower temperatures. These types of filters are generally used for obtaining clear filtrate, but it can also be used to obtain the cake that is retained on the filter media, between the plates. Salient Features The complete filter plate is manufactured by cold process. The sealing of the filter plate is done by the spinning process for better sealing. The cartridge assembly is provided with ‘T’ type side bolts for longer life. The filters are provided with gear/centrifugal/lobe pumps fitted with mechanical seals as per requirement. Optionally available with steam jacket for heating of liquids at the time of filtration. Scavenging Operation The unfiltered liquid remaining inside the shell at the end of filtration can be filtered by scavenging operation, opening the single plate valve and applying pressure from the vent using compressed air or nitrogen / inert gas, so that even the last drop of unfiltered liquid passes through the bottom plate. It is available in 14” & 18” Dia models as a standard and can be provided in 33” Dia model on request.

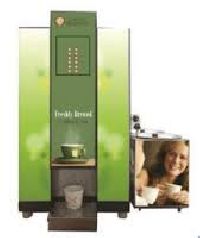

Filter Coffee Vending Machine

Get Price Quote

Rely on us for timely delivery as we are assisted with up-to-date transit facilities and logistics services. As a dependable name, we make sure that our products are of excellent quality. To make it possible, we use only quality-approved and certified raw materials sourced from reliable vendors.

Pulse Jet Bag Filter

Get Price Quote

Karyasiddhi is one of the leading names in pollution equipment design and manufacturing. We have proved our expertise through all of the Pulse jet bag filter installations all over India. All our units are designed to operate with a pressure difference of 100-125 mm W.G. In the pulse jet bag filter as name implies dust laden gas is spreads all over the bag filter through nozzles. The continuous passage of dust laden gas leads to accumulation of dust over fabric which increases pressure drop. It is been cleaned by the compressed air, passing through the blow nozzle, at very high velocity and for very short duration. This produces a shock wave, which is propagated down the bag length, causing the bag to expand and snap away from the cage, dislodging the dust cake, which falls into the hopper. Cartridge Collector : Second type is called the “Cartridge Collector Applications • Steel Industry Blast Furnace, Electric Arc Furnace, BOF, etc • Fertilizer Industry Phosphate Rock Dryers & Calciners, Dryers • Non-Ferrous Copper Reverberatory Furnace, Laea Blast Furnace • Pulp & Paper Lime Kilns, Back Liquor Recovery, Bark Boilers • Sugar Industry Boiler Flue Gas, Bagging Section • Mineral Products Asphalt Stone Dryers, Cement Kilns • Pharmaceuticals Tablet Coating Fans, etc

Compressed Air Filters

Get Price Quote

The ultimate KAESER Filter & Activated Carbon Adsorber is well founded and profit-making, true compressed air. The KAESER compressed air filters and activated carbon adsorber bring your system and provides reliable, highly competent safeguarding against dust, aerosols and oil vapours. Some of the outstanding features of KAESER Filter & Activated Carbon Adsorber are- Provides the Best Protection- It provides the highest level of protection including all purity classes according to the ISO 8573-1. The compressed air filter system is completely adaptable to the diverse range of our compressors and various other compressed air treatment alternatives. These KAESER compressor filters are provided with a pressure of 16bar, along with a high-pressure filter range of 45 bar and the filters are also present in the silicon-free version which can be used for painting processes. The activated carbon filter for compressed air operates at a flow rate of 1.80-36.7 m3/minute. It has a robust built of 1.4301 stainless steel housing which makes it corrosion free and works efficiently at the maximum working temperature of up to 66-degree centigrade. Dependable condensate drainage- The carbon filters are equipped with a high level of pressure coalescence filters which are manufactured with ECO-DRAIN that is an electronic condensate drain. Another manual tap drain is also provided for particles and for activated carbon filters. Wide Application Spectrum- The carbon filter for compressed air has five different kinds of filter grades which are available for operating pressures up to 45 bars ranging from pre-filters to activated carbon filters. And hence assures application-convenient filtration for the purity of entire section and classes as per ISO 8573-1with optimal pressure loss. The adsorber has a rotary screw compressor technology and is made up of a deep-pleated polyester fibre. It has an automation grade and can be reused. Operation-friendly Design- The carbon adsorber has a straightforward handling and is made of aluminium housing which eradicates the chances of corrosion. It is equipped with a stable filter element. There’s a pragmatic bayonet lock which assures automatic setting of the housing and elements seal. Because of the above mentioned incredible attributes of the KAESER Filter & Activated Carbon Adsorber, it can be used effectively. You can buy it online at the great discount and additional benefits along with warranty and cash on delivery perks.