Fixed Bed Reactor

Get Price Quote

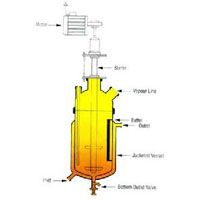

Fixed Bed Reactor/ Packed Bed Reactor / Fluidized Bed Reactor Multi-phase reactor systems are widely used in fine chemicals, oil and gas,petrochemical refineries, pharmaceutical, pesticides and in research centers.With the evolving needs of the industry for enhanced productivity and lowercost of production; Amar offers tubular reactor systems in continuous manner for various applications with system integration and automation which maximizes the efficiency and accuracy of research and production operations Salient Features Fixed Bed Reactor volume from 5cc to 100 ltrs. Higher volumes optional Designed up to 350 bar & 1000 °C. Higher ratings optional Various MOCs such as SS316, Inconel, Hastelloy etc. Explosion proof plants for highly explosive reactions/hazardous area Table top or skid mounted plants Either a standard or customisable unit can be offered for gas liquid feed combinations, product outlets, series or parallel reactors, multi zone heatingfurnaces etc. with integrated controls, high level of safety, automation andSCADA software Fixed bed reactor, fluidized bed reactor, trickle bed reactor designs offered Applications & system of packed bed reactor Catalyst testing, oxidation, reforming, hydrogenation, dehydrogenation,liquefaction, fischer Tropsch process, hydro-cracking, carboxylation, catalystscreening, fluid catalytic cracking (FCC), microreactor system, syngas reactorsystem, pyrolysis reactor system, packed bed reactor system, vapor rig system,biomass gasification system, hydroprocessing catalyst testing system, catalystreduction unit, multi-purpose reactor unit, vapor phase reaction system etc Table Top Reactor System (TTRS) The table top reactor system is very compact & complete semi or fully automated system for vapor phase catalyst evaluation and continuous flow process analysis.The reactor and feed lines are mounted within an isothermal oven. System Specifications: Reactor volume: 5-50 ml System pressure: Upto 200 bar Temperature rating (reactor): Upto 650 °C Temperature rating (oven): Upto 200 °C Description: Feeding section: Feed streams are provided for 4 reactants (2 liquids, 2 gases), the purge gas and the GC carrier gas. Feed lines includes bulk head union connectors, inline filters, metering valve, 3- way ball valve and check valve. Reactor section inside oven: Preheater & vaporizer: This section includes 2 coils for preheating gases and 2 coils for vaporizing liquids. Reactor: volume available from 5 – 50 ml. Reactor status valve: The optional multiport reactor status valve can permit reactor bypass. Sample valve: Sampling valve can be provided for transfer of sample of product to GC unit. Back pressure regulator: Manually operated (standard) with optional automatic control. Product collection section: Gas liquid separator: Volumes upto 250 ml will be placed after reactor and before back pressure regulator. Heated transfer line: It connects the sample valve to the gas chromatograph unit (supplied by client).

Fixed Bed Reactors

Get Price Quote

Multi-phase reactor systems are widely used in fine chemicals, oil and gas, petrochemical refineries,pharmaceutical, pesticides and in research centers.

Best Deals from Fixed Bed Reactor

Fixed Bed Reactors

Get Price Quote

Fixed Bed Reactors, Supercritical Fluid Extraction, shaker hydrogenator