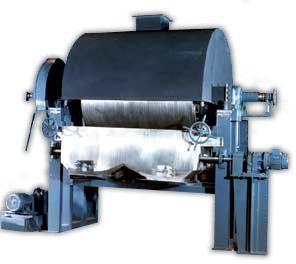

Industrial Flaker Machine

Get Price Quote

We are offering an optimum range of Industrial Flaker Machine to customers in the domestic as well as international market. Our offered Industrial Flaker Machine is designed and developed using high grade material of construction and latest technology as per the defined industrial norms and standards. We are a renowned Industrial Flaker Machine Manufacturer, Exporter and Supplier in Maharashtra (India). We make our product available in standard as well as customized options as per the customer’s requirements and at unbeatable prices.Working : Flakers are used for hardening molten material. It is a continuous process where hot material is applied on the cooling drum which is cooled on after a partial revolution. Further, the cooled and solidified product is removed by scraper in the form of flakes or film. Features : High thermal efficiency Designed for trouble free operation Minimum thermal degradation Accomplishment of flaking in a single step Low Cost operation Continuous Process Uniformly flaked product Material of Construction (MOC) Offered : CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ) SS 316, SS 304 SS 316 L SS 304 L. SS 310 Monel Inconel Titanium Hastalloy, etc

Flaker

Get Price Quote

The Flaking surface of the drum is duly ground and hard chromed with superior finish for fast and uniform formation of Flakes and prevention of dried material being stuck on the drum surface after scrapping. The drum is provided with a Hollow shaft for entry of Cooling medium. Rotary joint is provided on the hollow shaft at the Intel and Mist of Cooling medium. Some of our manufactured Flakers are installed at • Tinco Chemicals P Ltd. – Badlapur • Golden Chemicals P Ltd. – Mumbai

Best Deals from Flaker Machine

Ice Flaker 150 kg Eurfrigor

Get Price Quote

Production: up to 150 kgs. flaked ice daily• Storage: up to 38 kgs. integral capacity• Condensation A / W• Refrigerant R 404 A• Water outlet 24 mm• water supply connection true• Net-to-gross weight Kg 85/95• Dimensions x D x H: 74cm x 68cm x 93cm Model:IFES150ABrand:BriceMade In Italy

Flake and Ice machine

Get Price Quote

Our Rugged and heavy-duty design of condenser offers years of trouble-free operation, with the longest service life, its Super performance offers trouble-free operation, with much less maintenance probability than other brands. Energy-efficient our elaborately designed ice flaker evaporator offers a smooth operation, with high heat exchange efficiency to fulfill the energy-saving.

Ice Flaker Machine

Get Price Quote

Can be used for + 5 to + 350 C (Ambient temp.),Can be available with R 404A or R 22.Condensing units & Control panel assembled as an integrated unit.Needs only power & water supply.Capacities ranging from 0.3 T to 15 Tday.

soap flaker

Get Price Quote

It is designed to convert Molten Hot Liquid Soap to Solid & Cold form. Chill Drum is a big rotating drum, in which 8 to13 degree Celsius of chilled water circulates continuously. Molten Hot Liquid Soap comes on the top surface in centre of the Chill Drum from Soap Holding Tank (Feed Tank) through gravity, in the form of Lumps, a small drum whichis rotating just in same synchronize speed with bigger drum makes a thin layer of 1 to 2 mm of molten hot liquid soap. When this thin layer sticking with bigger drum during complete round, on the other surface end a hard carboned steel blade is fitted out, which scraps that thin layer of Soap. Now, nature of the Soap after scraping is Cold & Solid. At Last, Main function of the Soap Chill Drum is to convert Molten Hot Liquid Soap to Solid & Hard form continuously.

Flaker machine

Get Price Quote

The hot material is applied to the cooling drum by direct immersion into a trough, or indirect immersion using doctorapplicator rolls. The molten liquid is cooled on the cooling drum and after a partial revolution; the cooled and solidified product is removed by a scraper in the form of flakes or film. The cooling drum of the flaker is specially designed to provide an even cooling effect by having uniform and effective internal distribution. As a result, both high output and homogeneity of the product are possible.

Industrial Flaker

Get Price Quote

The Pragati Enginnering Works offers flaker, industrial flaker, chemical flaker, flaker machines to convert molten chemical in to solid flakes. This is achieved by forming a thin layer of molten product on the outside surface of a rotating drum and causing this to be solidified by spraying cooling water from inside surface of the drum. An adjustable scrapper continuously removes the solidified from the drum surface in flake forms. The material of construction for the drum can be mild steel,Stainless Steel with / with Hard Chrome Plating, normally Monoblock for weldable materials. This construction ensure lifelong alignment, surface will be machined and ground finished. Drum Rotating on antifriction self aligning ball / roller bearing with standard Housing. Heavy duty drive arrangement for smooth, continuous and trouble free running. V-Pulley or Variable speed arrangement also provided for optimum performance. The Flaker Machine will be complete with 1440 RPM, 3 Phase, 415 volts, TEFC / ISD motor, with gear box, Tray, Hopper, M.S. hood, Belt Guard. Machine mounted on heavy base-plate for trouble free service. It’s optional features is Screw Conveyor, Flaker Breaker, Film thickens controllers, Complete enclosure for Hazardous application. Company also providing pilot unit which is available for, to take running trial on receipt of sample about 15 Kgs. Company carries out the test on it, to produce reliable information’s on outputs and for the scaling of purpose. Flaker used inAcetanilide, Fatty acids, Monochloro acetic acid, Nickel catalyst, Naphthalene, Resin, Waxes and so many other products. Special Features:• Designed for trouble free operation• Low Cost operation• Continuous Process• High thermal efficiency• Minimum thermal degradation• Accomplishment of flaking in a single step• Uniformly flaked product

Flaker machine

Get Price Quote

These Ice Flakers are the most suitable Ice Flake Machines used in laboratories worldwide. With the use of international quality standard material and advanced manufacturing and designing technology, our units prove to be highly reliable and durable flake ice makers available on the market today. These systems are supplied to all over India with economical price and excellent warranty.

Flaker machine

Get Price Quote

Flaker machine, Sigma Mixer Machine, Octagonal Blender, Paddle Mixer

Flaker machine

Get Price Quote

Flaker machine, vertical boiler, Hammer Mill, Seed Cleaner, Oil Expeller