Fluidized Bed Reactor

2,000,000 - 20,000,000 Per Piece

1 Piece (MOQ)

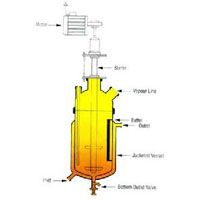

· Volume: 500 ml to 200 Ltr. Pressure Range: up to 12 bar Temperature Range: up to 1050°C · Amar has been leading manufacturer and exporter of fluidized bed reactors and systems in India since past many years. · A fluidized bed reactor is a vertical cylindrical tube having 2 sections i.e., reaction section & disengagement section. · Even temperature distribution throughout the burning zone, while solid catalyst particles are freely suspended using gas of high velocity. · Product is collected from top & solid residue collected from the bottom. · Solid Feed: - Batch/Continuous. · Uniform particle mixing. · Uniform temperature gradients. · Catalyst/solid can be fed from top/bottom while gas/liquid is fed from the bottom. · Explosion proof plants for hazardous area. · Automation: Customisable unit is offered for gas / liquid / solid feed combinations, product outlets, multi zone heating furnaces etc. with integrated controls, high level of safety, automation, and SCADA software Application: Packed Tubular reactors are extensively used in chemical and associated industries such as petroleum, petrochemical, oil and gas, mineral and coal industries, pharmaceuticals, fine and specialty chemicals, and biochemicals. Applications may vary considerably from industry to industry and may include cracking of large organic molecules into useful desired products, upgrading petroleum feedstock, conversion of unsaturated organics into saturated products, conversion of coal-derived products, syngas generation, pyrolysis reactions, biomass / coal gasification reactions, multi-purpose reactions, vapor phase reactions, conversion of gaseous reactants into fuels, hydrodeoxygenation (HDO) of bio-oils (upgrading), polymerization of monomers for a variety of commodity applications, liquefaction reactions, etc.

FLUIDIZED AEROBIC BED REACTOR

Get Price Quote

The FBR process is the latest advance in attached growth aerobic biological treatment technology. FBR employs RING PAC MEDIA, neutrally buoyant bio film carrier elements, to achieve outstanding BOD/COD removal productivity from a compact bioreactor. In Fluidized Bed Reactors, the liquid to be treated is pumped through a bed of small media at a sufficient velocity to cause fluidization. In the fluidized state the media provide a large specific surface for attached biological growth and allow biomass concentrations in the range 10-40 kg/m3 to develop. For aerobic treatment processes the reactor is aerated. This is done by recalculating the liquid from the reactor to an oxygenator where air, or possibly oxygen, is bubbled. To overcome problems related to high re-circulation rates, needed when there is high oxygen demand in the reactor, the reactor might be aerated directly. The basis for the use of fluidized bed systems is the immobilization of bacteria on solid surfaces. Many species of bacteria (and also other microorganisms) have the ability for adhering to supporting matrices. In this process, a volume of Ring Pac media is immersed in water and is fluidized (kept in constant motion) through the movement of gas and liquid in the treatment reactor. As the media supports a biomass concentration several times that achievable in activated sludge systems, treatment is significantly more productive. Advantages The FBR requires very less hydraulic retention time (HRT) compared to an extended aeration or activated sludge process to perform the same BOD reduction duty. High resident biomass concentration, intense mass transfer conditions and aggressive biomass-sloughing action enable the process to rapidly respond to variations in process load Less footprint area required for installation. Less operation and maintenance cost during plant operations.

Best Deals from Fluid Bed Reactor