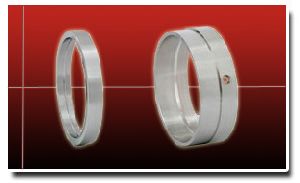

Inconel Forged Rings

1,500 Per Kilogram

1000 Kilogram (MOQ)

Round Forging Ring

Get Price Quote

Best Deals from Forged Components

Inconel Alloy 718 Forged Components

Get Price Quote

Harsh Steel is known for providing its customers Inconel Alloy 718 Forged Components that they can afford and use effectively. Inconel alloys are available in a wide range of shapes. Harsh Steel also offers forging services that include creating custom designs from raw materials. Inconel alloy 718 is a high-strength, corrosion-resistant nickel chromium material used at -423o to 1300oF. The age-hardenable alloy can be readily fabricated, even into complex parts. Its welding characteristics, especially its resistance to post weld cracking, are outstanding. The ease and economy with which Inconel Alloy 718 can be fabricated combined with good tensile, fatigue, creep and rupture strength, have resulted in its use in a wide range of applications. Examples of these Forged Components are liquid fueled rockets, rings, casings and various formed sheet metal parts for aircraft and land-based gas turbine engines and cryogenic tank age. It is also used for fasteners and instrumentation parts.More about Inconel Alloy 718 Forged Components :Inconel alloy 718, W.NR 2.4668, UNS N07718 is available at harsh steel in forms of Inconel alloy 718 Sheets, Inconel alloy 718 Strips, Inconel alloy 718 Round bars, Inconel alloy 718 Seamless and welded pipes and tubes. Inconel alloy 718 is supplied as per AMS 5663, AMS 5832, AMS 5962, and AMS 5662, ASTM B637 standards. Inconel alloy 718 is a Nickel and Chromium alloy which is precipitation hardenable and high temperatures to about 700°C (1290°F). It has higher strength than Inconel X-750 and better mechanical properties at lower temperatures than Nimonic 90 and Inconel X-750.Inconel alloy 718 Strips, Sheets and round bars Chemical composition : Nickel (plus Cobalt) - 50.00% - 55.00% Chromium - 17.00%-21.00% Iron - Balance Niobium (plus Tantalum) - 4.75%-5.50% Molybdenum - 2.80%-3.30% Titanium - 0.65% -1.15% Aluminum - 0.20% - 0.80% Cobalt - 1.00% max. Carbon - 0.08% max. Manganese - 0.35% max. Silicon - 0.35% max. Phosphorus - 0.015% max. Sulfur - 0.015% max. Boron - 0.006% max. Copper - 0.30% max

Stainless Steel Forged Hook

1,350 Per Piece

10 Piece(s) (MOQ)

Forged petroleum drilling ring

Get Price Quote

forged hollow cylinder

100 Per Metric Ton

5 Metric Ton (MOQ)

Stainless steel Forged Plate

Get Price Quote

We can produce 1.7734 EN 15CDV6 stainless steel forged plates 1.7734 EN 15CDV6 forging,sheet,coil,and profiledstrip,Deformed steel,flat steel,mould,steel wire,have all specifications. With production experience, strict control 1.7734 EN 15CDV6 chemical composition and 1.7734 EN 15CDV6 mechanical properties.From casting, forging, steel to hot and cold rolling process, heat treatment, etc, we have the control of professional engineers. We have advanced precision machining equipment, according to the requirements of users machining. in order to achieve the most satisfied with the user requirements.

Nickel Alloy 200 / 201 Rings

Get Price Quote

100 Kilogram (MOQ)

We are Exporter, Manufacturer and Supplier of Nickel 200 Circles & Nickel 201 in India. Nickel 200 has good ductility and low work hardening rate. Nickel 201 has high electrical and thermal conductivity. Alloy 200 Circle (UNS N02200) is ferromagnetic. It provides high thermal and electrical conductivity in comparison to nickel-base alloys, stainless and low alloy steels. Alloy 201 Circle chosen for applications involving exposure to temperatures above 315 Degree C (600 Degree F). Alloy 200 are often used for reactors and vessels in which fluorine is generated and reacted with hydrocarbons. Alloy 201 (UNS N02201) provides high thermal and electrical conductivity in comparison to nickel-base alloys, stainless and low alloy steels, because of its low carbon content. These nickel alloys are also being offered in made-to-order sizes and shapes to our customers.

Forged Plates

Get Price Quote

With the support of our hardworking team, we are occupied in offering a vast range of Mild Steel Forged Plate Flanges to clients. The provided forged plate flanges are appreciated and accepted for their optimum quality and durability. Besides this, offered flanges are thoroughly tested on a series of parameters to ensure its durability and optimum quality by quality checkers.

Forged Ring

Get Price Quote

2 Metric Ton (MOQ)

Forged Components

Get Price Quote

Ashapura steel & alloys offer forged components with different outlets and weldolets and as socket weld or screwed type. They are available in 15 nb to 100nb size and their outlets range from ¼” to 24” and they are available in hydraulic and instrumentation fitting as well. They are available in forms like elbow 45 degree and 90 degree, tee, union and full and half coupling. They are highly temperature resistant and pressure resistant and we manufacture them using high quality materials

Cold Forging Parts

2 - 52 Per Nos

Special Cold Forging Components

Get Price Quote

We are offering Special Cold Forging Components.

Brass Forged Components

10,000 Per Box

Type Available: Regular & Shot Blasted Standard & Specification: Developed specifically as per customer's mould design & requirements. Material Specification: CW614N (CuZn39Pb3), CW617N (CuZn40Pb2), CW602N(CuZn36Pb2As), CW511L (CuZn38As), Cuphin (CuZn21Si3P) or as per customer requirement. * No-Lead manufacturing also available.

Forged Rollers

Get Price Quote

The packaging commences under the strict supervision of experts and other team members; they ensure that the products are packed sternly to circumvent loss during transit. We offer secured online and offline payment processing methods. The transaction, done through online mode, is instantly forwarded to the payment system. We also accept bank account transfers, cash payments, etc. Features : Sturdy design Easy to install Rust proof

Metal Round Forged Component

Get Price Quote

Super Duplex Steel Forged Circle and Ring

Get Price Quote

Ring Rolling Component

Get Price Quote

Bronze forged components

Get Price Quote

We also manufacture and supply all types of bronze forged components. We supply both forged and finish components to customer depend on their requirement

Stainless Steel Forging Parts

Get Price Quote

Hot Forged Eye Hooks

Get Price Quote

We are offering hot forged eye hooks. we are one of the leading manufacturer of eye hooks, having a capacity to manufacture 0.5 tons to 160 tons of eye hooks ranging unto 1500 mm length. This eye hooks are made from fine material and with the art of technology to withstand high load capacity and durability. Eye hooks are available in m.s, alloy steel and in en-8 material. Eye hooks we manufacturer are used in many industries and had stabilized goodwill. available standard : i.s b.s ansi asme din or as per drawing size available : 0.5 tons to 160 tons capacity in hot forged length available : 25mm to 1500 mm in length material : mild steel, steel, carbon steel, alloy steel, en material, surface finish black colour, white plating, golden plating & hot dip galvanized

Forged Steel Ramshorn Hook

Get Price Quote

Hot Forging Parts

Get Price Quote

We are main supplier of this product.

Copper Forging Forged Parts Copper Forged Fittings

Get Price Quote

COPPER FORGINGS COPPER FORGED FITTINGS FORGED COMPONENTS AND PARTS CNC MACHINED COPPER PARTS Conex is a leading manufacturer and supplier of metal forgings forged fittings and forged components from India.We offer Forgings products in a number of materials including Copper Brass Bronze and stainless steel as well as non ferrous Copper alloys. Copper forgings are often used in the electrical industry , building industry as well as in marine applications due to their corrosion resistant and biostatic nature. Forgings are helful where due to uneven shape the part cannot be turned or CNC machiend evenly. Copper that undergoes cold forging and hot forging becomes extremely dense with a refined grain structure which allows forged copper products to reach very close dimensional tolerances. Additionally, the ductility of copper allows its forgings to reach a tight standard of uniformity during production of mass parts and components. This ductility also allows copper forgings to be hammered into smaller, thinner sections which resist cracking or developing flaws that lead to leakage. Copper forgings Copper sstamping hot pressing are often alloyed with other elements and achieve desirable characteristics including high impact and tensile strengths as well as resistance to corrosion or abrasion. The wide range of benefits associated with copper alloy stamping and forgings allows the product to be a cost-effective alternative to many other metals. We have in-house tool room and can offer comeptitive price for tool-making and prototype making. Copper forging hot stamping hot forging up to 5 kgs in each size Brass Forging bronze Aluminium forging Stainless Steel forgings Also offered CDA Copper alloys used: 101, 110, 145 377, 385 377, 385 636, 642, 675 CNC machined Copper forgings and precision swiss machining service available

Forging Accessories

4,200 Per Piece

1 Piece (MOQ)

die block

Get Price Quote

Die Block Size: ETC-5014Part No:H05014

forged tractor parts

Get Price Quote

Heavy & Medium duty Axle Assemblies & parts- Friction welded and press fit types. PTO shafts adapter, Weld on end- friction welded and other types, Top Links Super Links & parts, Linkage parts; Leveling Box assembly & parts, Hydraulic parts-Hydraulic Lift Shafts, Pump parts-Piston, Housing, End Plates, shafts, Valve chamber Body, Kits, Pressure Relief,& Control Valves and component parts.

Forged Rings

Get Price Quote

We are reckoned as a Forged Rings Manufacturer, Exporter and Supplier in the global markets. Made from the best material, our Forged Rings comply with international standards. The Forged Rings offered by us are a complete blend of latest technology and precision engineering by experts. Diameter: 100mm to 500mm Thickness: 25mm to 150mm Grade: 304, 304L, 316, 316L, 309, 310, 347, 321, 317, 317L, 904L etc Stainless Steel Forged Bar Standard : ASTM / ASME SA A182 Grade : 304 , 304L , 304H, 309S , 309H , 310S, 310H , 316 , 316L, 316H , 316Ti , 317L , 321 , 321H , 347 , 347 H , 409, 410S, 420, 430, 440A, 440B, 440C, 446, 904L. Duplex Steel Bar & Super Duplex Bar Standard : ASTM / ASME SA A182 Grade : F51, F53 UNS NO. S 31803 , S 32205 , S 32550 , S 32750 , S 32760, Carbon Steel Forged Bar Standard : ASTM 105, LF 2 Alloy Steel Forged Bar Standard :ASTM / ASME A/SA 182 Grade : F 5, F 9, F 11, F 12, F 22, F 91. Nickel Alloy Forged Bar Grade Nickel 200 Bar – UNS N02200 Nickel 201 Bar – UNS N02201 Monel 400 Bar – UNS N04400 Monel K500 Bar – UNS N05500 Inconel K600 Bar – UNS N06600 Inconel 601 Bar – UNS N06601 Inconel 625 Bar – UNS N06625 Inconel 800 Bar – UNS N08800 Inconel 800H Bar – UNS N08810 Inconel 825 Bar – UNS N08825 Hastelloy C276 Bar – UNS N10276 Alloy 20 Bar – UNS N08020 Copper Nickel Forged Bar C 70600 - COPPER NICKEL 90/10 Bar C 71500 - COPPER NICKEL 70/30 Bar Value Added Services Annealed/Solution Annealed. Hardened & Tempered. Strain Hardened. Centerless Ground. Centerless Ground & Polished. Cold Drawn. SmoothTurned & Polished. Forged & Peeled Buffed (Mirror finish). Rolling Cutting 100% Ultrasonically tested. Other Materials Cupro Nickel Bar Copper (Electrolytic ) Bar Brass Bar Aluminum Bar Lead Bar

Stainless Steel Forged Parts

20 Per Piece

Forged Rolls

Get Price Quote

Taking the industrial sector forward with the help of our range of forged steel rolls is something that we at Sunil Forgings take very seriously. We consider it an opportunity to be able to contribute to the growth and prosperity of a business when we are asked to supply the forged rolls. This is a major reason why we make sure that the products that we create for our clients are made as per the exact requirement. With the most accurate diameters and the perfect weights, our forging steel roll is created to suffice the need of the buyer with a high level of efficiency.The power of customization that we offer with our open die forging method is unmatched in quality by anyone in the industry, which is a huge identity of the experience and expertise that we hold in the field. With state of the art machinery and techniques, Sunil Forgings stands at a level where we have become one among the forging roll manufacturers in India. Our technical know-how and the professional approach have helped us achieve a position where we are considered as pioneer among makers of forged rolls India. Our drive to provide our patrons with nothing lower than the best is something that helps us grow in leaps and bounds and also ensures the smooth functioning of the business processes of our clients and patrons.