Spectacle Blind Flanges

800 - 900 Per piece

8 piece (MOQ)

Stainless Steel Spectacle Blind Flanges:ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904LAlloy Steel Spectacle Blind Flanges:ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91Carbon Steel Spectacle Blind Flanges:ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70, ASTM A350, LF2, LF3Duplex & Super Duplex Spectacle Blind Flanges:ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61, 2205 (UNS No. S31803), 2507 (UNS No. S32750)Copper Alloy Steel Spectacle Blind Flanges:UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)Nickel Alloy Spectacle Blind Flanges:ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020).

Slip On Flanges

Get Price Quote

We offer a range of Slip On Flanges that slide over the end of pipes and can be easily put in place. Ideal for pressure applications, these flanges can be availed in standard specifications and can also be customized as per client's specific requiremen

Best Deals from Pipe Flanges

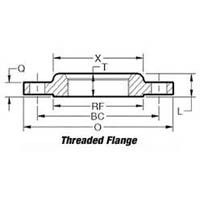

Threaded Flanges

200 Per Piece

1 Piece (MOQ)

Stainless Steel 304 Spectacle Blind Flange

Get Price Quote

1000 Piece (MOQ)

Threaded Flanges

Get Price Quote

Stainless Steel Slip On Flange

175 - 2,400 Per Piece

100 Piece (MOQ)

The slip-on flange has a low hub and is bored slightly larger than the OD of the pipe. This flange is welded on both inside and outside of the flange face to prevent leakage. Used in lieu of welding necks when cost or space is a major consideration. Grades: Stainless Steel 304 Flanges Stainless Steel 304L Flanges Stainless Steel 304H Flanges Stainless Steel 310/ 310H Flanges Stainless Steel 316 Flanges Stainless Steel 316L Flanges Stainless Steel 316H Flanges Stainless Steel 316Ti Flanges Stainless Steel 317/ 317L Flanges Stainless Steel 321/ 321H Flanges Stainless Steel 347/ 347H Flanges Stainless Steel 904L Flanges ANSI/ ASME B16.5 Flanges BS 10 Flanges DIN Flanges EN 1092-1 Flanges JIS Flanges

Slip On Flanges

Get Price Quote

We offer a broad array of Slip On Flanges, which is used to slide over the pipe-ends after which they are welded in the position. Our Slip On Flanges are ideal for easily fitting and welding into a variety of pipes that operate in a low pressure range, with the welding is responsible for reducing the cost of fabrication of the pipes. Our expertise in providing premium Slip On Flanges has made us a highly sought after Manufacturer, Exporter and Supplier from India for Slip On Flanges in different sizes and dimensions. Materials of Construction : Stainless steel Alloy Steel Carbon steel Alloy titanium Monels Titanium Plastics Brass Steel Aluminum Why our Slip On Flanges? Apt for fitting into all pipe sizes Pipes are easier to cut according to this type of flanges Leak proof Economical installation Assured accuracy of the cut pipe Easy alignment of bolting holes due to thinness of flange High strength due to welding on inside and outside Application Areas : Oil refineries Chemical plants Nuclear power plants Shipbuilding industry Paper industry Food industry Range : ½� (15 NB) to 48� (1200NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. Available with NACE MR 01-75 Availability : Stainless Steel : Grade : 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L, 317, 317L, 321, 347, 347 H, 409, 410, 410S, 420, 430L Duplex Steel : Grade : 2205 (UNS No. S31803), 2507 (UNS No. S32750) Nickel Alloy : Grade : Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) Copper Alloy : Grade : UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30) Standard : ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 B.S : BS4504 , BS4504, BS1560, BS10 Other : Plate, Plate Blank What we offer : Hot Dipped Galvanizing Heat Treatment CNC Machining Threading

Alloy Puddle Flange

Get Price Quote

Alloy Puddle Flange We are manufacturers of a wide range of Puddle Flanges. These flanges are manufactured in accordance with international quality standards using high grade raw material and cutting-edge technology. The offered flanges are available in different material and sizes to meet the varied application requirements of clients. Flanges provided by us can be availed in various dimensions at industry leading prices.

Stainless Steel Round Flanges

100 - 10,000 Per piece

10 Piece (MOQ)

Reducing Flange

Get Price Quote

10000 Piece (MOQ)

Threaded Flanges

Get Price Quote

1 Ton (MOQ)

Highly acclaimed Manufacturer & Supplier of Threaded Flanges, Carbon Steel Threaded Flanges, Stainless Steel Threaded Flanges, Alloy Steel Threaded Flanges, Inconel Threaded Flanges, Monel Threaded Flanges, Hastelloy Threaded Flanges in IndiaWe are largest manufacturers of Threaded Flanges & have huge stock of 304 Threaded Flanges, 316 Threaded Flanges, astm a105 Threaded Flanges, astm a182 Threaded Flanges as per asme / ansi B16.5 Threaded flanges, ansi B16.47 Threaded flanges, Din Threaded flanges, jis Threaded flanges & uni Threaded flanges Standards.We offer high quality Threaded Flanges in all size, classes & dimensions like Class 150 Threaded Flanges, Class 300 Threaded Flanges, Class 600 Threaded Flanges, Class 900 Threaded Flanges, Class 1500 Threaded Flanges & Class 2500 Threaded FlangesWe are a largest Manufacturer, Supplier and Exporter of Thread Flanges, ASME 16.5 Threaded Flanges. Threaded Flanges (Screwed flanges)are similar to slip-on flanges in outline, but the bore is threaded, thus enabling assembly without welding. This obviously limits its application to relatively low pressure piping systems. Threaded Flanges may be welded around the joint after assembly, but this is not considered a satisfactory method of increasing the flanges’ pressure applications. Threaded flange use in low press condition usually. These flanges are normally designed for low pressure, non-cyclic applications. They are also used in applications where welding is hazardous. Threaded flanges are widely demanded as pipe flanges i.e called as threaded pipe flanges used in different industrial applications. Threaded Flanges are available in following specifications:

Orifice Flange

Get Price Quote

10 Piece (MOQ)

Orifice Flange Standard Specifications Standards/Dimensions : ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605 Flange Face Types/Connection Type : Flat Face Flange (FF), Raised Face Flange (RF), Ring Joint Flange (RTJ), Lap Joint Flange, Male and Female Flange (M&F), Large and Small Tongue-and-Groove Flange (T&G) Material Test Certificates (MTC) : As per EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103 Test Certificates : 100% Radiography Test Report, EN 10204/3.1B, Raw Materials Certificate, Third Party Inspection Report, etc Tests : Hydrostatic testing machine, Direct-reading Spectrograph, UI trasonic flaw detector, X-ray detector, Magnetic particle detector Equipment/Machines : Press machine, Pushing Machine, Bending machine, Sand-blasting machine, electric bevelling machine, etc. Details : Orifice Flange Material Grades Orifice Flange Standards ASME B16.5 Orifice Flange Class 300 Dimensions ASME B16.5 Orifice Flange Class 600 Dimensions ASME B16.5 Orifice Flange Class 900 Dimensions ASME B16.5 Orifice Flange Class 1500 Dimensions ASME B16.5 Orifice Flange Class 2500 Dimensions How To Order Orifice Flanges? Orifice Flange Industries and Applications Orifice Flanges Supply and Export Network Orifice Flange Price and Other Flange Types Weld Neck Flange Long Weld Neck Flange Slip On Flange Spectacle Blind Flanges Socket Weld Flanges Blind Flanges / Dummy Flange Screwed / Threaded Flanges Orifice Flanges Lap Joint Flanges ANSI B16.5 Square Flanges Ring Type Joint Flanges Tongue and Groove Flange Expander Flanges Reducing Flanges Male & Female Flanges Weldolet Flange Nipolet Flange Backing Ring Flanges Ring Spacer Flanges Paddle Blind Flanges Plate Flange High Hub Blind Flange Custom Flanges Swivel Ring Flange

Carbon Steel Threaded Flange

Get Price Quote

100 Piece (MOQ)

Pipe flanges that are made to standards called out by ASME B16.5 or ASME B16.47 are typically made from forged materials and have machined surfaces. B16.5 refers to nominal pipe sizes (NPS) from ½" to 24". B16.47 covers NPSs from 26" to 60". Each specification further delineates flanges into pressure classes: 150, 300, 400, 600, 900, 1500 and 2500 for B16.5, and B16.47 delineates its flanges into pressure classes 75, 150, 300, 400, 600, 900. However these classes do not correspond to maximum pressures in psi. Instead, the maximum pressure depends on the material of the flange and the temperature. For example, the maximum pressure for a Class 150 flange is 285 psi, and for a Class 300 Flange it is 740 psi (both are for ASTM A105 Carbon Steel and temperatures below 100F). The gasket type and bolt type are generally specified by the standard(s); however, sometimes the standards refer to the ASME Boiler and Pressure Vessel Code (B&PVC) for details (see ASME Code Section VIII Division 1 - Appendix 2). These flanges are recognized by ASME Pipe Codes such as ASME B31.1 Power Piping, and ASME B31.3 Process Piping. Materials for flanges are usually under ASME designation: SA-105 (Specification for Carbon Steel Forgings for Piping Applications), SA-266 (Specification for Carbon Steel Forgings for Pressure Vessel Components), or SA-182 (Specification for Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service). In addition, there are many "industry standard" flanges that in some circumstance may be used on ASME work. The product range includes SORF,SOFF, BLRF, BLFF, WNRF (XS, XXS, STD & Schedule 20, 40, 80), WNFF (XS, XXS, STD & Schedule 20, 40, 80), SWRF (XS & STD), SWFF (XS & STD), Threaded RF, Threaded FF & LJ, with sizes from 1/2" to 16". We are involved in offering a large range of Carbon Steel Flanges in various sizes.

Stainless Steel Threaded Flange

Get Price Quote

To cater to different requirements, our Stainless Steel Threaded Flange is offered in ample of specifications. Our manufacturers make use of the highest quality Stainless steel for their production. Rely in us! Details : Stainless Steel - ASTM A 182, A 240 Carbon Steel - ASTM A 105, ASTM A 181 Alloy Steel - ASTM A 182, GR F1, F11, F22, F5, F9, F91 Nickel Alloys - Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22, C276 Copper Alloys - Copper, Brass & Gunmetal Size - 1/8" NB TO 48"NB Class - 150, 300, 400, 600, 900, 1500 and 2500 Features : Durable Reliable Long service life Low maintenance Corrosion free For SS Threaded Flange Feel Free to Email Us

Lap Joint Flanges

400 Per Piece

100 Piece (MOQ)

Lap Joint Flanges

Get Price Quote

10 Piece (MOQ)

puddle flange

Get Price Quote

Lap Joint Flanges

Get Price Quote

Made from premium steel and other metal alloys, our Lap Joint Flanges are highly demanded in the national and international market. The Lap Joint Flanges are used to help with bolt alignment for erection of piping with large diameter of unusually stiff structure. We take the utmost care to ensure integrity in the designing and manufacture of our Lap Joint Flanges that are made as per the clients specific requirements.Features : High metallurgical strength Easy installation Reliable performance Long service life Resistance to rust Application Areas : Petroleum industry Processing industry Steel plants Refineries Ship building Chemical industry Range : ½ (15 NB) to 48 (1200NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. Available with NACE MR 01-75Availability : Stainless Steel Grade - 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L, 317, 317L, 321, 347, 347 H, 409, 410, 410S, 420, 430L Duplex Steel Grade - 2205 (UNS No. S31803), 2507 (UNS No. S32750) Nickel Alloy Grade - Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) Copper Alloy Grade - UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30) Standard : ANSI - ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 DIN - DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 B.S - BS4504 , BS4504, BS1560, BS10 What we offer : Hot Dipped Galvanizing Heat Treatment CNC Machining Threading

Stainless Steel Butt Weld Flanges

220 Per Piece

1000 Piece (MOQ)

Stainless Steel Slip On Flange (sorf)

Get Price Quote

We are a quality provider of the slip on flange (sorf) which is widely used establish connection of pipes and deliver maximum level of stability in the functionality of these vital structures. The high levels of mechanical support provided by this product are widely appreciated by our clients and the structural engineers directly involved in the complete process. We provide the leverage to our clients to make the order according to their specifications and requirements. Our slip on flange have a number of dedicated buyers across the country and globally mainly due to the high levels of international industrial standards adhered to by us. The raw materials used have been tested and then used to confirm the robust and sturdy character of this product. Our product ensures accuracy and precision so that our clients get value for their money. Moreover, our range of sorf flanges or slip on flanges are offered at industry leading prices. The slip on flange is an attachment fitting that is secured to the end of a pipe for installation purposes. The hardness of this product is thoroughly checked and a detailed quality report is prepared to counter the future complications involved in this industrial domain. features: •stability maintained •experts involved •robust and sturdy flanges form : stainless steel astm a 182, a 240 flanges size : 18" nb to 48"nb. flanges class : 150, 300, 400, 600, 900, 1500 & 2500 flanges grade : f 304, 304l, 304h, 316, 316l, 316ti, 310, 310s, 321, 321h, 317, 347, 347h, 904l.

Raised Face Flanges

Get Price Quote

raised face (rf) flanges manufacturers, stainless steel raised face flanges stockists micron steel & tubes recognize as a trusted manufacturers, suppliers, & exporters of raised face (rf) flanges, asme b16.47/ansi b16.5 raised face flanges, series a & b raised face flanges, raised face forged flange, mss sp-44 raised face flanges, din86029 pn10 raised face flanges, class 300, 600, 900, 1500 raised face flanges dimensions. materials used in manufacturing of raised face (rf) flanges includes stainless steel(ss), hastelloy, monel, inconel, titaniun, duplex steel, nickel alloy, super duplex steel, incoloy, alloy 20, 254 smo, copper nickel, carbon steel(cs), alloy steel, aluminium, bronze, mild steel(ms), brass. as a leading manufacturers of raised face flanges. We, micron steel & tubes invest into resources, technologies and a workforce that is finest. These stainless steel raised face flanges serve the food processing, food and beverage, fmgc, and many more industries. A ss raised face flange is the most frequently used flange-type in process plant applications. Monel rf flanges are easily identified, as the gasket surface of the flange is raised above the bolting circle face. As a result, they are called ‘raised’ face flanges.

Lap Joint Flanges

Get Price Quote

Based in Mumbai, Maharashtra, we are the most trusted manufacturer, exporter and supplier of superior quality Lap Joint Flanges that can be availed in multiple material grades such as stainless steel, carbon as well as alloy lap joint flanges. The lap joint flanges supplied by us are pretty much similar to the other flanges but they do not come with a raised face. You can use these flanges in conjunction with the Lap joint stub End. The ability of this flange to hold the pressure is comparatively low and the fatigue is only one tenth when compared to the welding neck flanges. There are a number of benefits of using the lap joint flanges. You can easily swivel around the flanges and this makes the lining up of opposing flange bolt holes easier. There is no proper contact with the pipe this makes them corrosion resistant. Thus, the flanges will not corrode easily and might be salvaged. The size of the flanges can carry from 1/2 "(5NB ) to 48 "(1200NB). Our products can be globally availed by you in safe packaging and at affordable prices. Specification : Size : 1/2 "(5NB ) to 48 "(1200NB) Standards : ANS B 16.5 , ANSI B16.47 Series A & B , MSS SP44, ASA , API - 605 , AWWA, Custom drawings Pressure Rating : class 150 , Class 300< class 400, class 600, class 900 , class 1500 , class 2500 , PN6, PN10, PN!6 , PN25,PN40, PN64 etc. Carbon Steel Lap Joint Flanges : ASTM A 105/A105N ,A350 LF1, LF2CL1/CL2,LF3CL1/CL2,LF3 CL1/CL2,A694 F42,F46,F48,F50,F52,F56,F60 ,F65 , F70,F516.60,65,70 (Spectacle Blind flange , Spade flange ) , Steel RST37.2,C22.8 Stainless steel lap joint flanges: ASTM A182 F202,F304?304H,F316?316L,F316TI ,F310,F321,F904L Alloy Steel lap joint flanges : ASTM A 182F1, F5,F9,F11,F22,F91 Special Alloy lap Jooint Flanges : Duplex , Super Duplex , Nickel Alloys Flange face type : Flate face (FF) , Raised face (RF) Ring Type joint (RTJ) coating / surface treatment : Anti- rust paint , Oil Black paini , Yellow transparent , Zinc plated. Cold and Hot dip Galvanized Value added services : CNC Machining Customized flanges

SS Plate Flanges

Get Price Quote

Stainless steel Plate Flanges: ASTM A182, Astm A240Plate Flanges Grade: F 304, F 304L, F 304H, F 316, F 316L, F 316Ti, F 310, F 310S, F 321, F 321H, F 317, F 347, F 347H, 904L,Plate Flanges size: 1/8" NB TO 48"NBClass: Plate Flanges class 150, Plate Flanges class 300, Plate Flanges class 400, Plate Flanges class 600, Plate Flanges class 900, Plate Flanges class 1500 and Plate Flanges class 2500

Reducing Flanges

264 Per Piece

Threaded Flanges

Get Price Quote

1 Piece(s) (MOQ)

we are offering threaded flanges. threaded flanges look very similar to slip-on flanges but the main difference is that the threaded flange has been was bored out to match a specific pipe inside diameter. the backside of this center opening is then threaded with the relevant-sized tapered pipe thread. threaded flanges can be used in very high pressure services and their major advantage is that they can be assembled without welding. size : 12"nb to 60"nb in class : 150 lbs, 300 lbs, 600 lbs, 900 lbs, 1500 lbs, 2500 lbs din standard nd-6,10, 16, 25, 40 etc. specifications as per the international standard astm, asme, api, aisi, bs, ansi, din, jis, mssp, nace value added services hot dip galvanizing , epoxy coating, test certificate mill test certificate as per en 10204 3.1b

SS Threaded Flange

Get Price Quote

Orifice Flanges

Get Price Quote

ASME Opening Flanges, ASTM Hole Flanges, Stainless Steel Hole Flanges, Duplex Steel Hole Flanges, Monel and Inconel Hole Flanges, SS Hole Flanges Maker and Exporter in India. ASTM/ASME – A 182, SA 182, ASTM B247, B361, Aluminum Opening Flanges, Carbon Steel Hole Flanges, Nickel Amalgam Hole Flanges, supplier.Shasan Piping Solution is had practical experience in assembling high caliber of Hole Flanges. The primary capacity of an opening Flanges is to propose right of section to a funnel line for metering of gasses or fluids. A hole plate is stuffed together between a couple of Flanges when it’s being introduced in a funnel line and the entire tradition is alluded to as an opening rib amalgamation. Jack-tightens the social event make a basic cancelation of the hole plate. In the mean time, the hole plate, which is the metering mechanical assembly, contains a slim plate with a square edge, concentric, and round opening in the point of convergence. Two weight tap-openings are too entered in every Flanges for to gauge the disparity of weight all through the opening.Range :½” (15 NB) to 60” (1500NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. available with NACE MR 01-75.Features : Dimensional accuracy High efficiency Corrosion resistance Durable Excellent finish Details : Stainless Steel Standard - ASTM / ASME A/SA 182 Grade - F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L Titanium Standard - ASTM B381. Grade - Grade 1, Grade 2, Grade 4, Grade 5, Grade 6, Grade 7, Grade 9, Grade 19, Grade 23 Duplex Steel Standard - ASTM / ASME A/SA 182 Grade - F 44, F 45, F51, F 53, F 55, F 60, F 61 Copper Alloy Standard - ASTM / ASME SB 61 / 62 / 151 / 152. Grade - UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30) C 71640 Nickel Alloy Standard - ASTM / ASME SB 564 / 160 / 472 Carbon Steel Standard - ASTM A 105/A694/ A350 LF3/A350 LF2. Grade - F42/46/52/56/60/65/70 Low Temperature Carbon Steel - ASTM A 350 LF2 / A350 LF3 Alloy Steel Standard - ASTM A182 Grade - F1/F5/F9/F11/F22/F91 Nickel Alloy Standard : Nickel 200 – UNS N02200 Nickel 201 – UNS N02201 Monel 400 – UNS N04400 Monel K500 – UNS N05500 Inconel K600 – UNS N06600 Inconel 601 – UNS N06601 Inconel 625 – UNS N06625 Inconel 800 – UNS N08800 Inconel 800H – UNS N08810 Inconel 825 – UNS N08825 Hastelloy C276 – UNS N10276 Alloy 20 – UNS N08020

Plate Flanges

Get Price Quote

We are offering plate flanges. Plate flanges are special types of flanges that have raised face and back ups. Made from quality mill plates, these flanges have high weldability & hardenability. Our range of plate flanges can be availed in different dimensional specifications depending upon the requirements and their applications. advantages stainless steel plate flanges are produced from quality mill plate. Mill plate produced to the astm a240 and asme sa240 standards is virtually free of voids, non-metallic inclusions and other defects. The inherent corrosion resistance of stainless steel is enhanced by the superior grain structure offered by plate products over forged or cast products. as companies begin to look at life-cycle costing models, in almost every case, the slightly higher initial cost of stainless steel plate flanges is more than offset by the extended service life and the reduction of the normal maintenance costs. stainless steel plate flanges are a widely accepted alternative to cast or forged flanges in low pressure applications.

Socket Weld Raised Face Flanges

Get Price Quote

100 Piece(s) (MOQ)

Ring Joint Flanges

Get Price Quote

Chemtech Alloys Pvt. Ltd is one of the prominent manufacturers and exporters of Ring Joint Flanges & Ring Joint Flange. Our product range also comprises of Carbon Steel Flanges, Spectacle Flange and Slip On Flange Our range of stainless steel ring joint flanges is highly appreciated for strength, durability, reliability, corrosion resistance and close tolerances. These steel ring joint flanges conform to various Indian and international quality standards. Used in a number of industries, these steel ring joint flanges are supplied in various dimensional specifications.