Y-Type Strainer Valve

50 Piece(s) (MOQ)

Class 150 Flanged End Connections Sure Flow Class 150 ASME Flanged strainers are available in Carbon Steel and Stainless Steel. A Machined, tapered seat ensures a perfect fit for the removable, stainless steel screen. Size 2” and larger come complete with flanged blow-off cover, gasket & plug. 1 ½” and smaller come complete with solid threaded cover and gasket. May be installed in vertical or horizontal pipelines with blow-off connection at the lower end of the screen. ConstructionCarbon Steel : Body, Cover – ASTM A216 Grade WCB Stainless Steel : Body, Cover – ASTM A351 Grade CF8M All screens are Stainless Steel

Material : Stainless Steel

Type : Y

...more

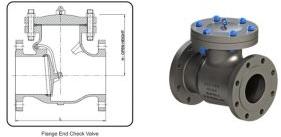

Swing Check Valves

We are the main supplier of this product.

Size : 5/6inch

Color : Silver

Pressure : High Pressure

Feature : Easy Maintenance., Blow-Out-Proof

Number Of Way : 2way

...more

Two-Piece Trunnion Mounted Ball Valve

100 Piece(s) (MOQ)

Material : Stainless Steel

Condition : New

Application : Industrial

...more

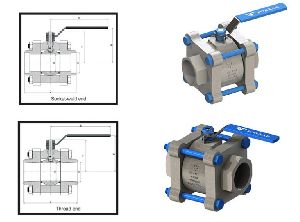

Two-piece Ball Valves Full Bore

Trunnion Mounted Ball Valve

Three Way Ball Valve

Standard Features Available in “T” or “L” Port configurations Full Port Actuator Mounting Pad Blow-out-proof stem Investment cast Benefits Reduces number of valves required in piping system Full port construction improves flow characteristics Standard mounting pad for ease of automation Live-loaded stem packing improves cycle life Balanced 4 seat construction provides for positive shut off Operating / Test Conditions: Operating Temperature Range -200 to 4500 F 100% air tested under water at 80 PSI Maximum Working Pressure :

...more

Three Piece Ball Valve

Stainless Steel Flanges

500 Piece(s) (MOQ)

Types : Weldneck SORF BLRF Slipon High Hub Socket Weld Flat Face Threaded Ring Type Joint Groove & Tongue Expander Spectacle Standards : ASME B16.5 ASME B16.36 ASME B16.47 API 6A EN 1092-1 EN 1098 BS 10 B2291 JIS B2220. Size 1/2” – 24” Pressure Rating Class 150 to Class 2500 PN 6 – PN 100 Table D, E, F. Features : Heat code traceability 100% material annealed & passivated High quality steel finish Three chambers cleaning system ( Surface preparation, Ultrasonic Degreasing, Hot Dry Air.) Notes : (For 150# & 300# Class) This dimension is for large end of hub, which may be straight or tapered. Taper shall not exceed 7 deg on threaded, slip-on, socket-welding, and lapped flanges. This dimension is defined as the diameter at the intersection between the hub taper and back face of the flange. The minimum thickness of these loose flanges, in sizes NPS 3 ½ and smaller, is slightly greater than the thickness of flanges on fittings, which are reinforced by being cast integral with the body of the fitting. For Class 300 these flanges may be supplied with a flat face. The flat face may be either the full tf dimension of thickness plus 2 mm or the tf dimension thickness without the raised face height. Dimensions in Column 15 correspond to the inside diameters of pipe as given in ASME B36.10M for standard wall pipe. Thickness of standard wall is the same as Schedules. To be specified by the Purchaser. 2.0 mm (0.06 in.) raised face for Class 150 and 300 raised face flanges

Material : Stainless Steel

Usage : Industrial

...more

Single Piece Ball Valve

Olets

We are offering Olets

Brand Name : FORXAR

Jacketed Type Ball Valve

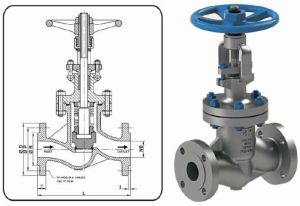

Globe Valves

Gate Valves

Forged Steel Globe Valve

Design Features Designed for quick and easy maintenance one step removal of all working parts including packing. All Pressure containing parts within one body-bonnet forging no joints to leak or welds to cut for servicing. Non rotating stem allows a non spinning disc, ensures low torque and prevents torsional damage of the packing. Fully enclosed, lubricated stem drive system with needle bearing ensures low operating torque. Solid CoCr alloy disc, seat ring and backseat provide excellent long service life even in severe services. Backseat bevel on the stem, not on the disc, satisfies both API-600 and API-602 specifications.

...more

Forged Steel Gate Valve

Design Features A compact but extremely sturdy design for high pressure temperature service. Solid CoCr alloy wedge (optional) ensures low friction and long service life. For Class 1500 valves and for steam service , seats are seal-welded to the body. Packing rings are precompressed to 4000 psi to provide a high intergrity seal. For welded bonnet valves, the bonnet is threaded in and torqued to an engineered value and the body bonnet joint is strength welded, offering double protection against leakage. (body/bonnet threads and strength-weld). Fully guided wedge reduces wear on seating surfaces. Repairable 2-piece stem drive. Optional Features (Special Applications) A special design is also available with double packing, leak-off connection, live-loading and a packing blowout for easy removal of old packing. Bolted Bonnet gate valves for alkylation service. Parallel slide gate valves. API 603 NPS 1/2 – 1 1/2 (DN 15-40), for ASME Classes 150, 300 and 600.

...more

Forged Steel Check Valve

Conventional Port Opening, Piston, Ball or SwingNPS 1/4-2 (DN 8-50), ASME CLASS 800, 1500 1) Ball type only. 2) Swing type only. 3) Bolted bonnet only 4) Piston or swing type only 5) Piston or ball type only 6) Bolted bonnet swing check disc CoCr alloy Gr. 6 only

...more

Flush Bottom Type Ball Valves

Features of Flush Bottom Ball Valves : Better flow capacity for line size. Suitable for drainage system. Tight closing for reliable shut-off even after change in pressure & temperature is sudden and extreme. Wide selection of actuator to meet stringent process requirement. Flexible design capabilities allows fitting in any vessel configuration. Measurement temperature is available with built-in thermometer. Jacketed option available (Full jacketed & Semi jacketed) Unique packing designs to suit various temperature & fluid needs. Excellent shut-off performance. Valve Size : NPS 1” to 8” ( DN 25 to DN 200 ) Pressure Rating : ANSI 150#, 300# & 600# Equivalent to BS 10, DIN, IS, JIS etc. Body Material : Carbon Steel, Stainless Steel, Duplex, Super Duplex, Monel, Inconel, Hastelloy, Aluminum, Bronze and Higher Alloys available on request. Plug Options : Contoured Flow Characteristics : ON – OFF End Connection : Flanged (RF, TG) Leakage Class : Class IV & V ( Metal to metal seated ) & Class VI ( Soft seated ) as per FCI 70-2 Temperature Range : -73 to 500°C Manual Over-ride : Top Mounted Version, Side Mounted Version Product Specification : Valve Size : NPS 1” to 8” ( DN 25 to DN 200 ) Pressure Rating : ANSI 150#, 300# & 600# Equivalent to BS 10, DIN, IS, JIS etc. Body Material : Carbon Steel, Stainless Steel, Duplex, Super Duplex, Monel, Inconel, Hastelloy, Aluminum, Bronze and Higher Alloys available on request. Plug Options : Contoured Flow Characteristics : ON – OFF Design Flexibility : The outlet flange is 45 Deg inclined to the axis of the valve. These valves are available in two types of constructions, one the plug opens into the vessels & second the plug opens into the valve body. These valves are available with actuators and manual operated. Special temperature sensing arrangement within the valve body itself also can be provided. Also the body can be provided with steam / oil / hot water jacketing arrangement to avoid solidification where in some application fluid tend to solidify at low temperature and discharged in hot condition only. These valves are compact, lightweight design and ideal for inline maintenance under the tank. Design Standard : Design Standard : ASME B16.34 & SFS EN 12516 Testing Standard : ANSI / FCI 70-2 Face to Face : As per manufactures standards Flange Fitting : ANSI B16.5, 150#, 300# & 600# Actuator Type : Pneumatic Diaphragm Actuator Pneumatic Cylinder Actuator Electrical Actuator Accessories : Pneumatic valve positioner Electro – Pneumatic valve positioner Air filter regulator Solenoid valve Limit switches Proximity switches Air lock relay Volume booster Other accessories available on request

End Connection : Flanged (RF, TG)

...more

Flanges

Double Eccentric Butterfly Valve

Accessories: Extension spindle Street covers Handwheel Stem cap for rod Adaptor gearside Post indicator Dismantling joint Combi-flange Adaptors different types of gearboxes and electric actuators Double eccentric butterfly valve, for water to max. 70° C, designed according to EN 593, Face to face according to EN 558 table 2 basic series 14. Standard flange drilling to EN1092-2 (ISO 7005-2) Hydraulic test according to EN 1074-1 and 2 / EN 12266. Features & Benefits Double eccentric designThe double eccentric design gives minimal wear of the disc seal, as the disc swings open/close like a door relieving the stress on the seal just after a few degrees of opening. The seal is fully compressed in closed position which gives 100% drip-tight closure. The disc and seat are designed to give the lowest possible operating torque in opening and closing direction at full differential pressure. Shaft sealingEncapsulated O-rings, self-lubricating bearings and bronze bushings protect against galvanic corrosion. Disc and seat designThe slim and streamlined disc design ensures low pressure loss across the valve, and the disc enables bi-directional flow. The seat is casted in the valve body, which is epoxy coated to avoid corrosion. The disc seals are mounted in a stainless steel retainer ring, and are exchangeable independent of flow direction. The disc is fixed by means of a keyway and set screws protecting against flutter between shaft and disc.

...more

Check Valve

Butterfly Valve

Integrally-molded Butterfly Valve sets a new benchmark in performance for butterfly valves. The versatile valve is offered in a variety of elastomer-disc combinations to address myriad process requirements. The highly reliable butterfly valve has successfully completed over 10,000 cycles at its rated pressure. Available in sizes from 50 mm (2”) to 600 mm (24“), the valve is available in Cast Iron, SG Iron and carbon steel, in a variety of body styles, materials and actuation options. The body seat of Aquaseal 16 Butterfly Valve is vulcanised insitu onto the body, which provides longer life and superior performance when compared to valves with loose liners. Feature & Benefits Longer LifeThe strength of the vulcanised liner as well as its strong bonding with the body ensure that it doesn’t get deformed and torn by the disc during valve operations. Further, friction during operations is minimized owing to the smooth liner surface. The strong seat and reduced friction greatly enhance service life of the valve. Tight Sealing and Consistent Low TorqueBubble-tight sealing is obtained by the tight interference fit between liner and disc. The insitu moulded seat does not deform with age, and hence the operating torque stays low and consistent during the entire life cycle of the valve. High reliability and consistent torque make Aquaseal the ideal valve for actuated systems. Assured Shaft SealingThe flat profiles on the top and bottom of Aquaseal Plus disc engage with matching profiles on the body liner, and the large area of contact prevents leakage to atmosphere. Integrally molded O-Ring that compresses around the blowout-proof shaft provide a secondary seal. Actuator Mounting PlatformThe integral ISO 5211 platform facilitates direct mounting of actuators and gear units, thereby improving system reliability and efficiency. Enhanced ReliabilityThe rugged body is designed to withstand pipeline stresses and vibrations. Further, enhanced liner thickness assures reliable performance over an extended service. Reinforcements are provided on Aquaseal disc also. Lower Torque, Longer LifeThe Aquaseal disc is profiled for smoother flow. Further the coating/ encapsulation of Nylon and EPDM on the disc helps to reduce torque and prevent disc damage. Reliable DriveIn Aquaseal a two-piece shaft is employed for closer control and smooth operation. The shaft is Xylan-coated to reduce friction and improve wear resistance. While the square shaft provides positive drive, the bottom shaft acts as a pivot for operational ease.

...more

Butt Weld Fittings

Bellow Sealed Valves

We are offering bellow Sealed Valves

Bellow Sealed Valve

WHAT ARE BELLOW SEALED VALVES? Bellow Sealed Valves are a new breed of industrial Process valves, designed to eliminate valve leakage and are also known as Zero Leak Valves or Emission Free Valves. In these valves, conventional gland packing is appended /supplemented by a metallic Bellow Cartridge joined to the valve bonnet at one end, and the stem at the other end. A bellow is a long accordion-like tube. As the valve stem strokes, the bellow expands or compresses with the stroke movement. The stem is fully covered with metallic bellow in wet zone, process fluid never reach to the gland area. Thus the fluid will enter the valve from the seat of the valve & come in contact with the bellow, but will not come in contact with the stem. Since the stem is the only moving part in the valve, it is a source of potential leakage through the gland due to constant friction caused by the axial movement. In a bellow sealed valve this potential leak through gland is totally avoided due to the metallic bellow which blocks the leak path effectively by not allowing the media to come in contact with the stem and thus the gland. A bellow is the heart of this type of valve. We use only formed bellows, as in spite of being more expensive than welded bellows, their life is many times more than welded bellows.

...moreBe first to Rate

Rate ThisOpening Hours