Wall Putty

Frigmaires are skilled professionals with a long and successful experience in the field of manufacturing and exporting wall putty plants.We have till date supplied and installed many wall putty plants in India. Frigmaires is a market leader in India's Wall Putty Industry, being one of the largest manufacturer,supplier and exporter. We are an ISO 9001:2008 certified company. Our wall putty plants meet the highest international standards as well as matching the Indian conditions.We supply wall putty plants designed for manufacturing a wide range of pre mixed mortars suitable for repairing, water Proofing, tile fixing,plasters and grouts.

...more

Vibro shifter

Vibro Shifter Is a highly efficient modular designed machine which imparts three directional vibrations on the screens. It is designed for all types of screening applications. The unit is run by a unbalanced vibrating motor with shafts at both ends. The machine is available in a number of decks and mesh sizes depending on the application. Output can be varied by simple adjustment of unbalanced weights on motor shafts. Units with dust covers are available to prevent dusting. All parts are easily removable and replaceable for manufacture.

...more

Used Transformer Oil

Transformer Oil or Dielectric Insulation Oil and other oils required for electrical machinery and installations can be manufactured using hydro finished base oils of group II +. The base stocks are selected based on viscosity requirements of the user. In colder countries pour point is also a critical property for base oil selection. Transformer Oil (TO) be used for filling the transformer with a primary objective of providing electrical insulation between the primary and secondary coils. Dissipation of heat generated during the process is also an important function. Electrical insulation is favored by high viscosity and heat dissipation is favored by low viscosity and circulation of fluid. Base oil viscosity at a compromise level is selected. Viscosity ranges for base oil slightly defer country to country, generally in the range of 10 to 40 cst. at 400 Degree C. During the service temperature of oil rises to about 60-800 Degree C. Viscosity of oil decreases due to temperature rise. Transformer has large extended surfaces exposed to atmosphere. The oil circulates through these tubes and dissipates heat into the atmosphere.

...more

TRANSFORMER OIL PLANT

Transformer Oil or Dielectric Insulation Oil and other oils required for electrical machinery and installations can be manufactured using hydro finished base oils of group II +. The base stocks are selected based on viscosity requirements of the user. In colder countries pour point is also a critical property for base oil selection. Transformer Oil (TO) be used for filling the transformer with a primary objective of providing electrical insulation between the primary and secondary coils. Dissipation of heat generated during the process is also an important function. Electrical insulation is favored by high viscosity and heat dissipation is favored by low viscosity and circulation of fluid. Base oil viscosity at a compromise level is selected. Viscosity ranges for base oil slightly defer country to country, generally in the range of 10 to 40 cst. at 400 Degree C. During the service temperature of oil rises to about 60-800 Degree C. Viscosity of oil decreases due to temperature rise. Transformer has large extended surfaces exposed to atmosphere. The oil circulates through these tubes and dissipates heat into the atmosphere.Transformer Oils are very sensitive to contamination by water or dirt and fibers as there are serious loss electrical properties. Dust particles and textile fibers absorb moisture and orient in an alignment or bridge to connected high voltage and low voltage side resulting into ‘Arcing’ and dielectric breakdown. While major breakdown are rare and lead to ultimate failure of machine, formation of small local arcs are common. It does not cause immediate damage to machine but damages the oil. These small arcs expose the oil to a very high corona temperature for split second, resulting into thermal breakdown of oil constituents. Some of these are gaseous and accumulate in the vapor space within the machine; others polymerize and settle down forming sludge. Over a period of time excess accumulation of gases and sludge may lead to serious dislocation of operation or even explosion. Thermal breakdown and oxidative degradation of oil could be reduced by incorporation of appropriate low temperature oxidation inhibitors and additives. Some users insist upon ‘uninhibited’ products in some cases oxidation inhibitors are to be blended. Manufacture of TOs therefore has following process steps.

...more

three roll mill

Used for grinding & dispersing of inks, paints, chocolates, carbon pastes, polymers, rubber, coatings etc. The machine consists of three rollers operating at different speeds. The material is fed between the first two rolls and is discharged from the final roll by a scrapper blade. The paste passing between the rolls is subjected to high stress & frictional forces resulting in the breaking up & separation of the particle to produce a finely dispersed film. The gap adjustment between the rolls can be done manually or hydrualically. Rollers are independently cooled by a water circulating facility. Rolls are available in S.S. 304 or Chilled Cast Iron construction.

...more

Thermoplastic Road Marking Paint

Brand Name : Frigmaires

Sturdy Design Dry Mix Mortar Mixing Plant

Brand Name : Frigmaires

Weight : As Per Model

Condition : New

Warranty : 1 Year

Application : Construction

...more

spray plastering machine

Wall plaster spraying machine is engineered by FRIGMAIRES in collaboration with BAUMANN, Germany. These are TuV, CE, GS and ISO 9001 certified and acclaimed for longer service life. These are engineered using best available techniques and following international industrial standard. These are admired for unique design, compact size and high functional efficiency.FRIGMAIRES iM4 is a very compact, flexible and efficient mixing pump.Up to 4 mm diameter. Fully equipped with a reliable compressor and a high performance water pump.iM4 Buddy is the all-rounder amongst plastering machines, well known in many markets. With a 200

...more

sodium grease

These are usually more or less fibrous in structure texture depending mainly on the nature of the fatty material, high unsaturation yielding very fibrous greases. They have high dropping points usually not less than 150ºC and sometimes as high as 200ºC and are useful for relatively high temperature service. Owing to the solubility of the soap in water they are not water resistant.

...more

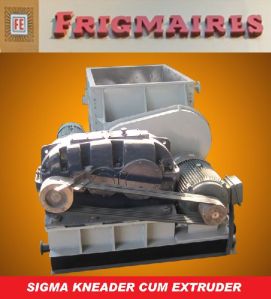

Sigma kneader

Excellent for kneading and mixing of highly viscous materials like dough, putty, rubber solutions, adhesives, polymers etc. The mixing action is a combination of smearing, stretching, folding, dividing and recombining as the material is processed between the sigma blades and the container walls. Jacket arrangement is provided for heating or cooling application. In bigger models the container is tilted by a hydraulic cylinder to ensure complete discharge of mass.

...more

Sand Mill

Used mainly by the paint, ink & coating industries for size reduction and dispersing of pigments in liquids. Particle size reduction upto 2 microns is possible in a single pass. The material to be processed is pumped from the bottom of the mill into the milling chamber which is filled with grinding media of 3mm dia. The media is agitated by a shaft fitted with a number of impeller discs along its length. As the material moves upwards it is subjected to high hydraulic & shearing forces between the grinding media which results in fine grinding of the material. This material then passes through the screen which separates the media from the process material. All mills are povided with a jacket arrangement for cooling the material in the grinding chamber.

...more

Putty Mixer

Putty Mixer is excellent for mixing of putties and high viscosity material. The discharge is from the bottom Valve. Two shafts run in opposite directions. The shafts are mounted on bearing blocks. The blades are fabricated from plates and are clamped onto the shaft for easy maintenance. The final drive run through rear gears in an oil bath. The entire machine is fitted on a sturdy frame fabricated to minimize vibrations.

...more

Plaster Machine

wall plaster spraying machine is engineered by frigmaires in collaboration with baumann, germany. These are tuv, ce, gs and iso 9001 certified and acclaimed for longer service life. These are engineered using best available techniques and following international industrial standard. These are admired for unique design, compact size and high functional efficiency. Frigmaires im4 is a very compact, flexible and efficient mixing pump. Frigmaires im4 buddy is designed to process almost all pumpable pre-mixed dry mortars of grain size up to 4 mm diameter. Fully equipped with a reliable compressor and a high performance water pump. Easy to disassemble and easy to transport. Frigmaires im4 your best buddy in every job site unique design, powerful, reliable im4 buddy is the all-rounder amongst plastering machines, well known in many markets. With a 200 lmin air compressor and powerful 5,5w pump drive it can handle most pumpable dry mixed mortars

...more

paint packing machine

Paint Filling machine suitable for filling of 30 Ltrsmin of Paint Distemper in Tins or Pouches. The machine is also suitable for filling 1 and 4 ltrs cans. The machine is complete with SS 304 contact parts & an electronic counter, one set of spare 'O' rings. The machine is provided with a S.S. 304, 40 liters capacity hopper for paint. The paint is to be fed pumped into the hopper after straining if necessary. The machine is driven 0.75 HP, 440 VAC, 3 Phase, and 50 Hz electric motor. The machine is provided with an electronic, two digits and digital preset counter for multi stroke filling. Thus the operator can preset the number of strokes to be filled on the counter enabling the machine to fill quantities upto 99 literskgs. Machine stroke can be set at say 1.0 kg per stroke and the counter at 05 strokes. Therefore the machine, once actuated, can fill 5.0 kgs & stop in each cycle.

...more

paint filling machine

Paint Filling machine suitable for filling of 30 Ltrs/min of Paint/ Distemper in Tins or Pouches. The machine is also suitable for filling 1 and 4 ltrs cans. The machine is complete with SS 304 contact parts & an electronic counter, one set of spare 'O' rings. The machine is provided with a S.S. 304, 40 liters capacity hopper for paint. The paint is to be fed / pumped into the hopper after straining if necessary. The machine is driven 0.75 HP, 440 VAC, 3 Phase, and 50 Hz electric motor. The machine is provided with an electronic, two digits and digital preset counter for multi stroke filling. Thus the operator can preset the number of strokes to be filled on the counter enabling the machine to fill quantities upto 99 liters/kgs. Machine stroke can be set at say 1.0 kg per stroke and the counter at 05 strokes. Therefore the machine, once actuated, can fill 5.0 kgs & stop in each cycle.Accuracy+/-0.5%. Filling capacity / stroke 200 to 1100 cc adjustable. Actuation By foot switch. Overall dimensions 500 mm W x 600 mm L x 1500 mm H. Loading & Unloading Manual. Nominal speeds 30 strokes per minute.

...more

oil insulation test kit

Transformer Oil or Dielectric Insulation Oil and other oils required for electrical machinery and installations can be manufactured using hydro finished base oils of group II +. The base stocks are selected based on viscosity requirements of the user. In colder countries pour point is also a critical property for base oil selection. Transformer Oil (TO) be used for filling the transformer with a primary objective of providing electrical insulation between the primary and secondary coils. Dissipation of heat generated during the process is also an important function. Electrical insulation is favored by high viscosity and heat dissipation is favored by low viscosity and circulation of fluid. Base oil viscosity at a compromise level is selected. Viscosity ranges for base oil slightly defer country to country, generally in the range of 10 to 40 cst. at 400 Degree C. During the service temperature of oil rises to about 60-800 Degree C. Viscosity of oil decreases due to temperature rise. Transformer has large extended surfaces exposed to atmosphere. The oil circulates through these tubes and dissipates heat into the atmosphere.

...more

Industrial Mixer

We are the main supplier of this product.

Type : Automatic

Certification : CE Certified

Application : Industrial Use

Voltage : 220V

Power : 1-3kw

Driven Type : Electric

Warranty : 1 Year

After-Sales Service Provided : Spare Parts

...more

Lubricant Filling Machine

Our auto grease filling machine has tin lifting arrangement which is provided for efficient grease lifting purposes. This auto grease filling machine is electro pneumatically operated and made by using excellent grade stainless steel and mild steel. It is known for its low electricity consumption as it requires only 415 V of alternating current. Our auto grease filling machine is widely demanded in packaging lines of different industries for providing smooth packaging operation and high accuracy. Furthermore, it is also equipped with volumetric filler and transfer conveyor.

...more

LUBEOIL BLENDING PLANTS

A typical blending plant comprsies of the following sections : Tank farm Blending area Storage, Filling And Packing Base oils from the tank farm are pumped into the blending vessels and mixed with additives at the required temprreature to obtain a homgeous mix.there are several methods to achieve and optimum blend depending on the product and plant requirments. The blended product is then filtered and transferred to storage tanks from where it is taken to the filling station and packed in containers or barreles.the entire process can be carried out in a basic manually operated plant or auotmated plc controled plants The lube oils are manufactured to api or other required specifications LUBE OIL BLENDING PLANT FRIGMAIRES OFFERS COMPLETE PLANTS ON A TURN KEY BASIS FOR THE PRODUCTION OF A WIDE RANGE OF LUBRICANTS.THE SERVICES OFFERED BY US INCLUDES PLANT DESIGN.DETAILED ENGINEERING SERVICES,TANK FARM DESIGN,EQUIPMENT MANUFACTURE AND SUPPLY,ERRECTION AND COMMISIONING.LAB SET UP.TRAINING .FORMULATIONS.RAW MATERIAL SOURCING AND SUPPLY.PLANTS ARE TAILOR MADE TO MEET THE PROJECT COST AND LOCAL MARKET CONDITIONS.TPYES OF LUBRICANTS AUTOMOTIVE LUBRICANTSINDUSTRIAL LUBRICANTSMARINE LUBRICANTSSYNTHETHIC LUBRICANTSPLANT LIST BLENDERS(ABB.ILB.SMB) PIGGING UNITS DRUM DECANTERS FILLING LINES FILTERS THERMIC FLUID HEATRES COOLERS/HEAT EXCHANGERS TESTING EQUIPMENTSAUTOMATION AND SCADAPIPING AND INSTRUMENTATIONLABORATORY PLANTSSKIDS AND PLATFORM MOUNTED PLANTS

...more

lube

Our auto grease filling machine has tin lifting arrangement which is provided for efficient grease lifting purposes. This auto grease filling machine is electro pneumatically operated and made by using excellent grade stainless steel and mild steel. It is known for its low electricity consumption as it requires only 415 V of alternating current. Our auto grease filling machine is widely demanded in packaging lines of different industries for providing smooth packaging operation and high accuracy. Furthermore, it is also equipped with volumetric filler and transfer conveyor. Specifications Packing range: 200 gm to 5 Kg. Capacity 34-36 Cans / Min. for 200 gm 20-24 Cans / Min. for 1 Kg 12-14 Cans / Min. for 2 Kg 8-10 Cans / Min. for 3 Kg 4-6 Cans / Min. for 5 Kg Filling accuracy: ± 0.5% of HPS At S. O. P. and S. O. C. Operation: electro-pneumatic Electric supply: 415 V AC, 3 Phase Power consumption: 5.5 HP Approx Air supply: @ 6 kg/cm2 Air Consumption: 120 LPM Man Power reqd: 2 Nos Space requirement: 6.1 Mtr. x 1.5 Mtr. IN-Feed Conveyor: Construction: dodge type Track width: 250 mm Height: 800 mm Length: 1000 mm + 2100 mm (in-feed + filler Guide rails: Adjustable Drive: HP gear motor Operation: electrical, through V/F drive Volumetric Filler: Filler: augur type volumetric type timer base [as per attached specs.] Range: 500 gm to 5 Kg Can lift auto infeed: pneumatic for cavity killing System: using infeed valve actuator assy. (40 mm) photo sensor operated Transfer conveyor (for lid dispenser & presser): Construction: S.S. slat belt type Belt width: 190 mm Track width: 250 mm Height: 800 mm Length: 3000 mm Linear Speed: 14 mtrs per min Guide Rails: adjustable Drive: ½ HP gear motor Operation: electric Technical Specification (Filler Unit): Material: industrial grease - temperature: 70-80 degree centigrade Range: 0.5 to 5 kg., in tins / pails Hopper capacity: 35 Ltr. approx. made out of 16 swg., S.S. 304 sheet Product feed: automatic through actuated valve having auto level control Material flow: by rotating auger Flow control: digital programmable timer Fill setting: with key pad switches Fill accuracy: ± 0.5% of HPS at S.O.P. & S.O.C. Filling rate: 300 gms. / sec Augur control - by E / M clutch break unit Drive transfer: using ‘V’ belt Augur drive motor: 1 H.P., 3 phase, 415 V A.C. Mixer / wiper drive: using additional gear motor cap. 0.5 HP with suitable starter Power supply: 415 V A.C., 3 phase 4 wire 230 V A.C., 1 phase 3 wire Compress air supply: @ 6 kg / cm² Consumption: 40 LPM General construction: the machine fabricated out of M.S. angle, sheet etc, hopper and all other contact parts are made out of S.S. 304 and wiper strips of PTFE

...more

Alkyd Resin Production Line Plant

After-Sales Service Provided : Online support, Engineers available to service machinery overseas

Type : Alkyd Resin Plant

Automatic Grade : Automatic

Voltage : Frigmaires

Weight : As Per Model

Warranty : 1 Year

...more

Horizontal Super-Mill

Horizontal Super mills are used for processing of inks, paints & coatings etc etc where a high level of size reduction & dispersing is required. Grinding & dispersing takes place in a pressurized chamber. A shaft fitted with wear resistant impeller discs agitates the grinding media.. Particle size reduction in sub micron size is possible in a single pass. Mills are equipped with a cooling chamber as a standard feature.

...more

gyro shaker

Gyro Shaker Machine is useful for blending a variety of paints, plasters, lacquers, spackling compounds, chemicals and many other hard to mix compounds in a very short time say 2-3 minutes. The machine enables effective mixing, uniform blending and homogenous mixing. The machines are maintenance free reliable and guarantees smooth and trouble free operation.

...more

GREASE PLANTS

Grease is a fine dispersion of an oil-insoluble thickening agent - usually soap in a fluid lubricant which is generally mineral lubricating oil. The soap is made up of fatty acid, tallow or vegetable oil saponified with alkali which can be hydrated lime, caustic soda, lithium hydroxide or aluminum hydroxide. The lubricating oil component is refined base oil-naphthenic, of medium viscosity index, or cylinder oil stock.Structurally grease is a “water-in-oil” emulsion. Its appearance is smooth, mostly translucent, soft or hard.Properties essential for performance of grease are structural stability, lubricating quality, low and high temperature performance (which are provided by the selected lube oil base stock), where as properties such as water resistance, high temperature quality, resistance to break down through continuous use and ability of grease to stay in place are provided by the soap.Additives eg. Graphite, modified clay, asphalt, oxidation and corrosion inhibitors, extreme pressure additives melybdenum disulphide etc. are used to impart specific properties as required by end application. UNIT PROCESSES AND UNIT EQUIPMENT IN GREASE MANUFACTURING. 1. Pumping of raw material from storage tanks into day tanks 2. Raw materials measurement by volume or weight using weighing scales, meters, tank gauges etc.3. Preparing the soap by heating and premixing fat and lube oil in kettles with counter rotating scraper stirrer operated by motor and reduction gear.4. Cooling of the prepared soap and balancing with oil to prepare grease in a cooling kettle.5. Formation of grease structure by dispersion in a milling machine under controlled moisture and temperature parameters.6. Deareation using deareator.7. Filtering through filter.8. Filling using weigh scales/ filling machines.9. Instrumentation - indicators/recorders for temperature and pressure.10. Pumps- gear and centrifugal for lube oils, vegetables oils, liquid soap and grease at various stages of manufacturing.11. Material handling equipment like hoist, pallet trucks, and fork lifts to handle solid fats, additives, alkali, drums etc.12. Safety and fire protection devices.13. Lab equipment14. Utilities like hot oil system, cooling system, air compressor, water etc

...more

Thermoplastic Road Marking Paints

Thermoplastic Road Marking Paint is the best marking system and is premixed with glass beads evidently visible and reflective throughout day and night. The paint is offered in both yellow and white colors with exceptional shine and whiteness. Our paint is examined and approved by quality auditors and are made available as per the requirements of our clients and can be offered at industry leading prices. Further, this paint is environmentally friendlier with no carcinogenic solvents used. Features Color stability Superior weathering resistance Long lasting retro reflectivity Excellent wear resistance

...moreBe first to Rate

Rate ThisOpening Hours