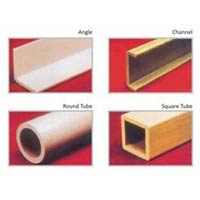

pultruded fiberglass sections

Get Price Quote

Material : FRP

Color : White, Grey, Yellow etc.

Application : Industrial

Thickness : 5-12 mm

Length : 3-6 m

Surface Treatment : Color Coated

Ever last Pultrudd Fiberglass Sections provide an unique and unmatched combination of corrosion resistivity, high strength, thermal & electrical non-conductivity, dimensional stability and light weight sections providing virtually maintenance free services in most harsh industrial environments where traditional materials like steel, aluminum or wooden have failed to provide all the above properties. These FRP Sections are widely used as a better alternative to stainless steel and other expensive components. Compared to these materials, the manufacture of ever last pultruded FRP products produces fewer air and water emissions, consumes less energy and emits less greenhouse gases, leading to both reduced environmental impact and lower carbon footprint. Ever last FRP Composite products have high resistance to rot and corrosion, a longer and more economical service life and require less frequent energy-intensive maintenance and replacement. These inherent advantages lead to superior overall sustainability for our FRP products. Ever last FRP pultruded sections include angles, channels, I-Beams, wide flange beams, round, rectangular & Square Tubes, Round and square bars, flat sheets, concrete embodiment angles, etc. Ever last FRP pultruded sections are manufactured using highest quality materials under stringent quality check and testing norms coupled with better service delivery. Large volumes can be delivered within short span of time thereby adhering to strict deadlines with the help of best in class infrastructure and quality & trained workforce. IMP : Custom sections can also be manufactured which are specific to certain applications and as per the requirements. Key Characteristics of Ever last FRP Pultruded Sections Maximum Corrosion Resistance : Responsible for Enhancing the life of the product in harsh environments subject to extreme corrosion conditions in industries. High Strength and light weight : This property of FRP allows dependable support to applied loads providing higher strength to weight ratio as compared to any other material. Thermal & Electrical non-conductivity : Very essential characteristics ensuring highest safety standards for the personnel working there. Dimensions stability : The product is so designed which maintains cross-section of shapes based on low co-efficient of thermal expansion. Electromagnetic transparency : The products does not interfere with the transmission of radio and microwave frequencies Product Applications Walkways & Bridges Electrical insulating sections Cooling tower sections Cable Tray Systems Maintenance platforms Pipe and equipment racks tank loading platforms Trash and bar screens Decks Ladders and hand rails Fencing & signboards Building and sheds Mezzanines Booths Baying platforms