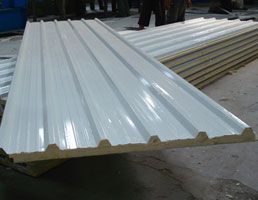

Sandwiched (PUF) Panels

Sandwich Panels are cost-efficient prefabricated elements that consists of an inner insulation core between two colour-coated steel sheet layers. The insulating core can be mineral wool or polyisocyanurate. Sandwich Panel is a structure made of three layers: low density core inserted in between two relatively thin skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression.

...more

Highway Gaurd Rail Roll Forming Machine

Roll forming, also spelled roll forming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing parts with long lengths or in large quantities. It can also produce parts of multiple lengths from the same tooling. Virtually any material that can be formed using sheet forming techniques can also be roll formed. Roll forming may also be an excellent solution whenever consistency of the cross-sectional profile is critical.

...more

Floor Decking Roll Forming Machine

Roll forming, also spelled roll forming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing parts with long lengths or in large quantities. It can also produce parts of multiple lengths from the same tooling. Virtually any material that can be formed using sheet forming techniques can also be roll formed. Roll forming may also be an excellent solution whenever consistency of the cross-sectional profile is critical.

...more

Corrugated Sheet Roll Forming Machine

Roll forming, also spelled roll forming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing parts with long lengths or in large quantities. It can also produce parts of multiple lengths from the same tooling. Virtually any material that can be formed using sheet forming techniques can also be roll formed. Roll forming may also be an excellent solution whenever consistency of the cross-sectional profile is critical.

...more

Bare Profiles Sheets

Colour coated and bare Roof and Wall sheets are manufactured from galvanized and also zinc aluminium alloy coated high tensile steel. The sheets are available in attractive range of colours. In brands like JSW, Essar, Uttam and Bhushan Steel.

Feature : • Smart appearance with subtle square fluting, • Accurate thickness, width and length gives a perfect fit for any roof

...more

Coil Slitting Machine

Slitting is a type of metal cutting process where large rolls, or coils, of sheet metal stock are cut using extremely sharp rotary blades. In metal slitting, straight lines are cut lengthwise into the large coil to create strips of metal that are narrower in width. As the coil runs through the slitter, circular blades – one upper, the other lower – make the cuts. These are commonly called knives and can be moved to make sheet metal strips of differing widths. In metal fabrication, slitters often come equipped with multiple knives. Slitting blades are designed depending on the job required. The three critical determinants of the blade configuration include: • the work piece material thickness • the type of material to be slit • the tolerances that must be held while slitting. We provide coil slitting machine for slitting of coils from width of 50mm to1500mm and thickness ranging from 0.2mm to 3mm. Our slitting line works on plc which operates decoiler, slitting line and re-coiler.

...more

Roll Forming Machine

Roll forming, also spelled roll forming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing parts with long lengths or in large quantities. It can also produce parts of multiple lengths from the same tooling. Virtually any material that can be formed using sheet forming techniques can also be roll formed. Roll forming may also be an excellent solution whenever consistency of the cross-sectional profile is critical.

...more

Automatic Decoiler

Decoilers also known as uncoilers, are designed and engineered for a smooth efficient unreeling of coil material into a cut to length line with a load capacity up to 10 ton. The Machinery is manufactured in various sizes for different coil loads. Our decoilers cater to nearly the entire market of sheet metal working, with a maximum width of 1550 mm which are universal and adapted to all kinds of coil widths.

...more

c z purlin roll forming machine

Highway Guardrail Roll Forming Machine

Cable Tray Roll Forming Machine

Metal Roofing Profile

color coated sheet coil

Be first to Rate

Rate This