vacuum vessels

As we are the name on which the customers lay their trust for quality, as we are supplying the finest Vacuum Vessels. Delivering the orders on time is one of our specialties for which we are highly admired by the clients. Technical Specifications : Glass Jacket can be used for a maximum operating pressure of 0.5 bars and a maximum o operating temperature of 130oC in jacket. The temperature difference between jacket & vessel 0 should not be exceeding than120oC.Vacuum Jacket Ensures : Transparent insulation Minimum heat loss Process visibility Minimize frost formation for cryogenics operation Vacuum Jacket & Main Vessels are Detachable Ensures : Ease of cleaning No breakages due to thermal expansion Partial Replacement of any part can be possible reduce the Maintenance cost

...more

Vacuum Jacketed Vessel

For special applications, we manufacture, supply, and export Vacuum Jacketed Vessel with a jacket for heating or cooling. Our Vacuum Jacketed Vessel is sealed to the vessel with Viton 'O' ring and other sealing compositions. The seal prevents high stresses between vessel and jacket by allowing the movement flexibility between two due to thermal expansion. Moreover, we provide Vacuum Jacketed Vessel at the most competitive prices to our clients. Technical Specifications : Glass Jacket can be used for a maximum operating pressure of 0.5 bars and a maximum o operating temperature of 130oC in jacket. The temperature difference between jacket & vessel 0 should not be exceeding than120oC. Vacuum Jacket ensures : Transparent insulationMinimum heat lossProcess visibilityMinimize frost formation for cryogenics operation Vacuum Jacket & main vessels are detachable ensures : Ease of cleaningNo breakages due to thermal expansionPartial Replacement of any part can be possible reduce themaintenance cost

...more

scientific glassware

Rotary Film Evaporator

We are a prominent Manufacturer, Exporter and Supplier of Rotary Film Evaporator in Mumbai, India. Our evaporator is automatic and corrosion resistant. We make available evaporator in different sizes and technical specifications to meet the diverse demands of buyers. We provide Rotary Film Evaporator that is widely used in various industries such as pharmaceutical, R&D. bulk drugs and many more. Our Evaporator is ideal for heat sensitive materials. Capacity : 2 ltr � 100 ltr Raw Material Used : An electrically heated SS heating bath with facility for raising and lowering the height.Rotating flask of corrosion resistant borosilicate glass which is connected to drive by a coupling.

...more

Reactive Distillation Unit

100,000 - 1,500,000 Per Piece

1 Piece (MOQ)

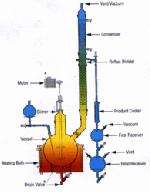

The unit has been designed to suit the customers requirement of combination of versatile reaction / distillation or combination for pilot plant work. This has a flexibility of working at atmospheric pressure as well as under vacuum. Typical unit has a reaction vessel fitted in a metal heating/cooling bath having facility for heating and cooling bath by means of heating/cooling Fluids as a media. The Standard system is equipped with stirrer heaving mechanical seal, a packed column on the side neck of the vessel, reflux divider, coil type condenser and or receiver system having a product, cooler, vent, drain and vacuum valves, Option of speed variation by machanical variator or electronic variator can be provided. Receiver system is equipped with product cooler. Vent / vaccum valve and drain valve. The above unit are available in 10 Ltr., 20 Ltr., 50Ltr.,100 Ltr., 200 Ltr. & 300Ltr capacity with spherical reactor.

Driven Type : Mechanical

Condition : New

Power : 10-15kw

Power Source : electrical

...more

Reaction Distillation Unit

This Unit is Used for Carrying Out Reactions Under Stirred Condition and with Provision for Simple Reflux Distillation. the Reaction Vessel is Mounted in a Heating Bath and Fitted with Addition Vessel, Motor-driven Stirrer and Provision for Condensation with Refluxing. the Product is Sub-cooled and Collected in a Receiver. the Units are Available in Vessel Sizes of 20, 50, 100 & 200l and is Suitable for Operation Under Atmospheric Pressure and Full Vaccum.

...more

Pilot Plant

Our Pilot Plant is manufactured using 3.3 borosilicate glass in order to assure the finest quality. Condensation, fractionation and stirring are some of the functional features of our Pilot Plant. The plant that we offer is highly durable in nature due to its strong and sturdy construction. Our plant is corrosion resistant and can withstand adverse climatic conditions. WE make available Pilot Plant with different technical specifications to be used in various industries such as chemical, R&D and many more. Raw Material Used : Excellent corrosion resistance to very large number of chemicals, unmatched by other materialSmooth pore free surfaceClear visibility Features : Solvent Recovery PlantBench Scale Reaction UnitsGlass Pilot Plant AssemblyMultipurpose Reaction SystemsJacketed Reaction Units Brief about product : We offer our customers with an intriguing range of Industrial Pilot Plant that are made with quality materials of construction and conform to international quality standards. These plants have been standardized with all the basic and essential functional features such as heating, stirring, condensation, fractionation and cooling. They have several multipurpose uses and have high durability. Solvent Recovery Plant, Bench Scale Reaction Units, Glass Pilot Plant Assembly, Multipurpose Reaction Systems, Jacketed Reaction Units

...more

Laboratory Glassware

Our Laboratory Glassware is known for its dimensional accuracy and excellent quality. We are one of the leading Manufacturers, Exporter and Suppliers of glassware in Maharashtra, India. The glassware, we provide is manufactured using 3.3 grade borosilicate glass ensuring the best quality and durability. Our Laboratory Glassware is widely used in laboratories, R&D and chemical industries. We believe in delivering Laboratory Glassware within the promised time frame. Technical Specifications : All Glass items shown are manufactured from borosilicate glass 3.3 are widely used as the basis for the construction of complete process systems all over the chemical, dyestuff, food pharmaceutical, and petrochemical industries. The abbreviation for the coefficient of linear expansion which is (3.3 ± 0.1) x 10-6 K-1 . This is lower than any other industrial glass. Since this glass expands less, the tensile stresses in the glass wall during heating are less, which means that it is able to withstand a greater thermal shock and the maximum working pressure for a given operating temperature is greater. One reason for this widespread used is the special properties of borosilicate glass 3.3 (see below), complemented by the use of other highly corrosion resistant materials such as PTFE and ceramics

...more

Jacketed Vessels

Transparent insulation, easy to clean and requires low maintenance are some of the key features of our Jacketed Vessels. Our vessels are manufactures as per the international quality standards ensuring the best quality and longer life. The vessels that we provide are known for their excellent quality. It can withstand variant temperatures and pressures. We make Jacketed Vessels with different technical specifications to meet the diverse demands of buyers. Features : Vacuum Jacket ensures Transparent insulationMinimum heat lossProcess visibilityMinimize frost formation for cryogenics operationVacuum Jacket & main vessels are detachable ensures Ease of cleaningNo breakages due to thermal expansionPartial Replacement of any part can be possible reduce the maintenance cost Technical specification : Glass Jacket can be used for a maximum operating pressure of 0.5 bar and a maximum o operating temperature of 130 C in jacket. The temperature difference between jacket & vessel 0 should not be exceed than120o C. Brief about product : For special applications, cylindrical vessels can be supplied with a jacket for heating or cooling. Jacket is sealed to the vessel with Viton 'O' ring and other sealing compositions. The seal prevents high stresses between vessel and jacket by allowing the movement flexibility between two due to thermal expansion

...more

Industrial Glassware

We are an affluent Manufacturer, Exporter and Supplier of Industrial Glassware in Mumbai, Maharashtra. Our glassware is manufactured using borosilicate glass ensuring the best quality. The Industrial Glassware that we offer is widely used in chemical, pharmaceutical, food and in many other industries. Our glassware can be installed in both horizontal and vertical pipelines ensuring maximum visibility of flow. Buyers can acquire Industrial Glassware fro us at reasonable price. Sizes available : DN25 to DN450 Special Features : All Glass items shown are manufactured from borosilicate glass 3.3 are widely used as the basis for the construction of complete process systems all over the chemical, dyestuff, food pharmaceutical, and petrochemical industries. The abbreviation for the coefficient of linear expansion which is (3.3 ± 0.1) x 10-6 K-1 . This is lower than any other industrial glass. Since this glass expands less, the tensile stresses in the glass wall during heating are less, which means that it is able to withstand a greater thermal shock and the maximum working pressure for a given operating temperature is greater.One reason for this widespread used is the special properties of borosilicate glass 3.3 (see below), complemented by the use of other highly corrosion resistant materials such as PTFE and ceramics

...more

Hospital Equipments

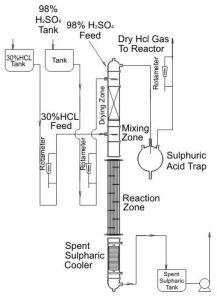

HCL GAS GENETRATION ( SULPHURIC ACID ROUTE )

Commercial hydrochloric acid is available in the market as 30% aqueous solution and is widely used in industry in large quantities. But for certain application e.g. in bulk drug pharmaceutical industry HCL gas is required in anhydrous state for critical reactions where moisture cannot be tolerated. Such users generate anhydrous HCL from commercial grade for their captive consumption. Several methods have been adopted but generation through SULPHURIC ACID ROUTE is the most reliable and handy technique. Salient Features 1. Operational reliability - the unit can be startedstopped in seconds. 2. Compact and continuous unit - all operations viz. drying, mixing, gas generation and cooling achieved in same unit. 3. Available in wide range capacities - from ± 5kg to 200kghr of dry HCL. 4. Except cooling water no other utility e.g. Steam, chilled water etc. are required. 5. Anhydrous gas. 6. Ease of installation. 7. Capable of operating from 25-120%. 8. Negligible pressure drop. 9. High efficiency - 99% Raw Material Requirement The indicative requirements for 20 kghr HCL gas generator are given below: 1. 30% HCL - 70 2. 98% H2SO4 - 170 3. Cooling water 2 m³hr

...more

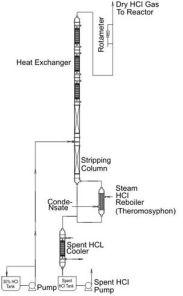

HCL GAS GENETRATION

Commercial hydrochloric acid is available in the market as 30% aqueous solution and is widely used in industry in large quantities. But for certain applications e.g. in bulk drugpharmaceutical industry HCL gas is required in gaseous form. Such users generate anhydrous HCL from commerical grade for their captive consumption. Several methods have been adopted and genertion through BOILING ROUTE is also a reliable technique. Salient features 1. Operational reliability 2. Available in wide range capacities - from 10kg to 200kghr of dry HCL. 3. Except commercial hydrochloric acid, no other raw-material is required. 4. The spent acid about 21% HCL usually finds use for captive consumption. 5. Capable of operating from 25-100% . 6. Easy of installation. 7. Negligible pressure drop. Raw Material & Utility Requirements The indicative requirements for 20kghr HCI gas generator are given below 1. 30-32% HCI, (kghr) : 250 2. Cooling water at 30°C (M3hr) : 3.5 3. Chilled brine at - 10°C (M3hr) : 4 4. Saturated Steam at 2.5 Kgscm² - g (Kgs) : 50

...more

hcl gas generator

We form a combination of Chemical Engineers in the field of Process engineering and itsapplication in the glass equipments/process packages.DESIGN AND SUPPLY OF VARIOUS UNITS as per client`s requirement are as under: 1. Absorption systems for gases such as HCl, Cl2, SO2, HBr. NH3, Br2, NOx etc. 2. Anhydrous HCl Gas Generation Unit by different routes viz. - Sulphuric Acid Route - Boiling Route - Calcium Chloride Route - Cyclic Route 3. HBr Gas Generator (By Boiling Route) 4. Sulphuric Acid Dilution Units. 5. Hypochlorite Manufacturing Units 6. MCA Condensation Assembly 7. Distillation - Conversion of Batch Process to Continuous Process. 8. Solvent Recovery 9. Iodine Recovery 10. Raw DCB Plant. KNOW-HOW WITH PLANT for the following products : 1. Bromine recovery from industrial waste / salt bittern 2. Nitric Acid Concentration. 3. Sodium Hypochlorite

...more

Hcl Gas Absorber( Falling Flim Type )

We are offering The Falling Film Absorbers are typical Heat Exchangers with weir tube arrangement at the top - which is always vertically mounted. In Falling Film Absorbers gas to beabsorbed enters atthe top of FFA and flows co currently with absorbent liquid coming from storage tank by pump.Heat of solution released as a result of the absorption process is removed by the cooling water flowing in the shell - side of the falling film unit. Thus noxious gas absorption is effected at lower temperatures enablinga higher absorption rate than adiabatic absorption towers. The absorbed gas leaves at the bottom of FFA at a very low temperature for storage and disposal. The un - absorbed gas and any inert gases also leave via vent at the bottom of FFA and enter the venturi scrubber or bottom of tail gas tower scrubber as is shown in the figure. Falling film absorbers can be used for absorption of gases like HCl Cl2 So2 NOX HBr – where higher efficiencies of absorption are required.

...more

Hcl Gas Absorber ( Adiabatic Type )

We are offering Process Description HCL absorption columns are used for absorption of Hydrochloric gas, which statutorily are not permitted to vent into the atmosphere, and to produce the HCI acid. The column is constructed with a series of packed sections, a gas introduction point below that, a condenser on the top, and a cooler at the bottom. Make water is sprayed from the top and acid is collected from the bottom. HCL absorption columns are available in 80DN to 300DN diameter (for the gas rate 10 Kgshr to 300 Kgs hr approx).

...more

Glass Stirring Assembly

glass reaction distillation assembly

Glass Reactors Kilolab are multi-purpose pilot plant units having flexibility of utility. Glass Reactor/distillation unit have been standardized by incorporating all basic & essential features such as heating, stirring, condensation, fractionation, cooling etc. for multi-purpose use. Therefore, though termed Kilolab from constructional view point they actually serve as Flexi Units from utility point of view, also known as Glass Reactor and distillation unit. These glass reactor kilolab are used in educational institutions, R&D centers and industries. Distillation unit can be conveniently and quickly modified according to specific process needs due to modular construction. Borosilicate glass offers additional benefits of universal corrosion resistance, visibility and cleanliness.

...more

glass pipelines

Borosilicate glass 3.3 pipeline offer many advantages for its use in chemical, pharmaceutical industries together with precious metal refining, dye works & electroplating because of its following characteristics. Inert to almost all chemicals, hence no risk of contamination and no unwanted flavors or colours are imparted into product. Transparency allows visual monitoring of the process, flow patterns, colour changes etc. Almost universal resistance to corrosion. A long service life is guaranteed. Smooth surface permits easy cleaning and prevents fouling. All the components are suitable for operation under full vacuum conditions. Pipeline Components are available from DN 15 to DN 600. DN 800 pipeline parts are available on request.

...more

Glass Lined Reactor

100,000 - 1,000,000 Per

Country of Origin : India

Type : GLASS

Brand Name : GARG

...more

glass equipments

Glass Distillation Column

12,000 - 100,000 Per

Material : Glass

Thickness : 0-5mm

Condition : New

Capacity : 0-1000L

...more

glass column components

Glass Column: In many operations like reaction, extraction & absorption, the transparency of glass is particular advantage. For such process a range of glass column components are available in Borosilicate glass. Advantages of Glass Column: 1. Insert to almost all chemicals hence no risk of contamination. 2. Transparency allows visual monitoring of the process, flow patterns, colour changes etc. 3. Almost universal resistance to corrosion. 4. Smooth surface permits easy cleaning and prevents fouling.

...more

Fractional Distillation Unit On Glr

Buyers are free to place orders and can expect timely deliveries of the same. As, our organizations is a suppliers of Fractional Distillation Unit on GLR; purchasers can place wholesale orders for it, and get them at the lowest prices.

...moreBe first to Rate

Rate ThisOpening Hours