Industrial Valves

We are considered a trusted Manufacturer, Supplier and Exporter of Industrial Valves from Mumbai, Maharashtra. We assure of the quality of our valves which are fabricated using high grade components and latest techniques. Owing to our efficient logistic structure, we are capable of delivering small or bulk orders of Industrial Valves all over the world.

...more

Structures Fittings

That is why we are a celebrated Manufacturer, Supplier and Exporter of Structures Fittings from Mumbai, Maharashtra. Mainly used for supporting glass structures, our Structures Fittings are highly popular for their precise designs and high dimensional stability. We are highly proficient in handling bulk orders of Structures Fittings for our clients from all over the world.

...more

Simple Distillation Unit

We are the noted Manufacturer, Exporter & Supplier of especially designed Simple Distillation Unit. The unit contains a vessel mounted in a heating bath and fitted with a condenser to condense the fumes. Our Simple Distillation Unit is available in vessel size of 20ltr, 50 ltr, 100ltr, 200 ltr, and 300 ltr. It is suitable for operations under the atmospheric pressure and full vacuum. The receiver with drain valve can be added for receiving the condensate. Optional Items Available With It : Heating mantel instead of jacketed heating/cooling bath Flush bottom valve instead of drain valve Cylindrical vessel instead of spherical vessel

...more

ptfe labware

Our company is a distinguished Manufacturer, Supplier and Exporter of PTFE Labware from Mumbai, Maharashtra. Our Labware are highly demanded in various medical establishments, laboratories, etc. because of their high durability and long working life. Our PTFE Labware are appreciated in various countries and can be availed at reasonable costs. Introduction : GARG SCIENTIFIC INSTRUMENTS Laboratory Ware And Accessories Are Designed For Use Under The Most Severe Laboratory Conditions. Superior Performance Results From The Out Standing Properties Of PTFE, FEP And PFA Fluoropolymer Resins And The Techniques Used In Their Fabrication GARG SCIENTIFIC INSTRUMENTS Has Perfected The Means Of Fashioning Laboratory Ware From Fluoropolymer Resins Which Have An Unmatched Combination Of Chemical Inertness, Heat Resistance, Low Temperature Toughness And Non Adhesive Qualities. The Resulting GARG SCIENTIFIC INSTRUMENTS Products Are Exceptionally Safe And Reliable For The Most Critical Laboratory Experiments. HEAT & COLD RESISTANTY PTFE AND PFA Can With Stand Continues Heat As High As 500 F (260° C) While FEP Can With Stand Continues Heat Of 480 F (205°C) PTFE< FEP And PFA Can With Stand Intermittent Heat To 600 F (315°C) 550 F (288°C) And 500 F (260°C) Respectively. Experience Has Shown That Exposure To These High Temperatures Does Not Affect The Utility Of GARG SCIENTIFIC INSTRUMENTS Laboratory Ware Products. Fluoropolymers Also Have Out Standing Low Temperature Toughness And Flexibility. It Restains Its Useful Properties Down Through The Cryogenic Range. In Addition To The Properties Inherent In Fluoropolymer Resins, GARG SCIENTIFIC INSTRUMENTS Laboratory Ware Brings You These Special Advantages : Extra Smooth Surface Resulting From The Finest Moulding Equipment & Techniques Assure Easy Through Cleaning Easy To Handle Products Are Light In Weight Familiar In Shape Styled For Easy Handling. Properties of Garg Scientific Instruments scientific Instruments Ptfe Products Non - Stick : Very few solid substances will permanently adhere to a "Garg Scientific instruments Scientific instruments PTFE" coating. And while tacky materials may show some adhesion, almost all substances release easily. Non - Wetting : Since " Garg Scientific instruments Scientific instruments PTFE" surfaces are both oleo phobic and hydrophobic, they are not readily wet. Clean-up is easier, more through and in many cases self-cleaning. Heat Resistance : There is no decomposition of "Garg Scientific Instruments Scientific instruments PTFE" finishes below 400o F; insignificant decomposition between 400 and 500 F which requires no special precautions. From 500 to 575 F, intermittent service is possible with adequate ventilation. Low Coefficient of Friction : The coefficient of friction of "Garg Scientific Instruments Scientific instruments PTFE" is generally in the range of 0.05 to 0.20, depending upon the load, sliding speed and particular “Garg Scientific Instruments Scientific instruments PTFE" finish used. Cryogenic Stability : Many "Garg Scientific instruments PTFE" will withstand severe temperatures extremes without loss of physical properties. "Garg Scientific Instruments PTFE" may be considered for use at temperatures as low as -450o F. Unique Electrical Properties : Over a wide range of frequencies, "Garg Scientific Instruments PTFE" has high dielectric strength, a low dissipation factor, and very high surface resistivity. By special techniques, it can be made conductive enough to be used as an anti-static coating. Chemical Resistance : "Garg Scientific Instruments PTFE" is normally unaffected by chemical environments. However, certain coatings are permeable or have a lower resistance to attack. The only chemicals known to affect all "Garg Scientific instruments PTFE" finishes are the alkali metals and highly reactive fluorinating. Types of PTFE Labwares : ptfe Beakers, Ptfe Lid, Ptfe Bottle Narrow Mouth with Screw Cap, Ptfe Vessel or Jars with Screw Cap, Ptfe Bottle Wide Mouth with Screw Cap, Ptfe Crucible, Ptfe Lid, Ptfe Magnetic Stirrer Bar, Ptfe Policeman (or Magnetic-retriver), Ptfe Stirrer Guides, Ptfe Stirrer Guides, Ptfe Stirrer Guides, Ptfe Stuffing Box with Stirrer Guide, Ptfe Mercury Seal, Ptfe Stirrer Plain with S.s. Rod, Ptfe Stirrer Rod Plain, Ptfe Thermometer Pocket, Ptfe Watch Glass, Ptfe Hexagonal Stoppers,Ptfe Homogenizers (tissue Grinder), Ptfe Plain Test Tube with Round and Flat Bottom, Ptfe Test Tube with Screw Cap Round, Ptfe Test Tube, Ptfe Plain Centrifuge Tube, Ptfe Centrifuge Tube, Ptfe Centrifuge Tube, Ptfe Test Tube or Centrifuge Rack, Ptfe Vials , Ptfe Vial Rack , Ptfe Evaporating Dishes, Ptfe Dishes Crystallizing, Ptfe Dishes Assay or Culture Petri, Ptfe Tray Drying (heavy Wall), Ptfe Gas Wash Bottle with Screw Cap, Ptfe Dropping Bottles, Ptfe Conical Flask Narrow Mouth, Ptfe Conical Flask Wide Mouth , Ptfe Conical Flask with Screw Cap, Ptfe Digestion Vessel , Ptfe Transfer Container, Ptfe Tube or Sleeve Thin Walls, Ptfe Tube or Sleeve Heavy Walls, Ptfe Reduction Adaptor, Ptfe Expansion Adaptor, Ptfe Gas Inlet or Outlet Tube, Ptfe Solid Spherical Balls, Ptfe Raising Rings, Ptfe Scraper, Ptfe Relative Density, Ptfe Weighing Bottles, Ptfe Cap Liner, Ptfe Stop Cock, Ptfe Sleeve, Ptfe Volumetric Flask, Ptfe Iodine Determination Flask, Ptfe Bellow Adapter, Ptfe Redistributors for Columns, Ptfe Packing Support for Columns, Ptfe Funnel 60o , Ptfe Desicators, Ptfe Sight Glass Packing, Ptfe Valve Bellow, Ptfe Valve Bellow Cap Only (gft) , Ptfe Expansion Bellow, Ptfe Vaccum Expansion Bellow, Alluminium Bellow Flanges, Ptfe Garg Scientific Instruments Type Crescent, Ptfe Garg Scientific Instruments Expansion Envelope Gasket, Ptfe Stirring Assembly Bellow, Ptfe Sheets, Ptfe Stirrer Blade.

...more

Pipeline Components

We are into the business of manufacturing, exporting and supplying different types of Pipeline Components. Our borosilicate glass pipeline components find universal application in chemical, pharmaceutical, food and drink and other allied industries. Pipeline Components with a standard flat buttress ends are available from DN 25 to DN450. Moreover, for standard flat buttress end connections from DN25 to DN300, it is possible to achieve a 3o deflection in the joint by using a flexible gasket. Our Pipeline Components such as 90o bends, tee pieces and equal crosses are interchangeable. DN refers to the nominal bore unless & otherwise it is stated that all dimensions are given in mm.Benefits : With almost universal resistance to corrosion, a long service life is guaranteed and maintenance is kept to a minimum. Their transparency permits visual monitoring of the Process at all times. Being inert, the risk of contamination is negligible. Smooth surfaces allow easy cleaning and sterilization and prevent the build-up of solid on the inner walls. Available Items : Pipe Sections types Pipe Sections Reducers 90oBends 45oBends Tee Equal Tee Equal Long Tee Unequal Crosses Equal Pipe Closure Hose Connector 90o Reducing Bends 90o Bends with Thermometer Branch

...more

Temperature Indicators

We are a widely acclaimed Manufacturer, Supplier and Exporter of Temperature Indicators based in Mumbai, Maharashtra. Manufactured in compliance with set industrial norms, our Temperature Indicators are precisely designed and show a highly accurate result. Our huge logistic network ensures that small or bulk orders of the product are delivered to the buyer well within the stipulated time.

...more

liquid Extraction Unit

Liquid Extraction Unit that we manufacture, export and supply is also known as solvent extraction unit in which separation of constituents of a liquid solution is done by contacting it with another insoluble liquid. Our Liquid-Liquid Extraction Unit is for semi-batch operation. We make available our Liquid Extraction Unit in vessel size of 10, 20 and 50 ltr. It is suitable for operation under atmospheric pressure. Functioning : The extracted liquid is poured into an extraction vessel and the solvent is in a reboiler vessel and condensed in an overhead condenser. The condensed liquid is then collected in a reflux divider and passes through pipework to the extraction vessel. The pipework incorporates valves in order that the solvent can enter the extraction vessel at either the base or the top, depending on the elative densities of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and process is repeated unit the extraction is complete. The extraction vessel is then drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enabling the two liquids to be drained from their respective vessels.

...more

Industrial Stirrers

Our company has garnered reputation as the Manufacturer, Supplier and Exporter of Industrial Stirrers from Mumbai, Maharashtra. The Stirrers offered by us can be used for various functions like boiling, monitoring of various processes, controlling reactions etc. Our buyers can avail an assortment of Industrial Stirrers at highly affordable rates.

...more

HCL Gas Absorber

Our company is a famed Manufacturer, Supplier and Exporter of HCL Gas Absorber from Mumbai, Maharashtra. Our HCL Gas Absorber is highly popular for its superior performance and long functional life. We offer HCL Gas Absorber in quality and sturdy packing and can transport them to any country within the promised time. Process Description : HCL absorption columns are used for absorption of hydrochloric gas, which statutorily are not permitted to vent into the atmosphere, and to produce the HCL acid. The column is constructed with a series of packed sections, a gas introduction point below that, a condenser on the top, and a cooler at the bottom. Make water is sprayed from the top and acid is collected from the bottom. HCL absorption columns are available in 80DN to 300DN diameter (for the gas rate 10 Kgs/hrto 300Kgs Ihr approx).

...more

Glass Jacketed Vessel

We present to our esteemed clients with Glass Jacketed Vessel that are used for various chemical reactions. Made from strong and durable glass, our vessel can withstand strong reactions with ease. That is why we are a celebrated Manufacturer, Supplier and Exporter of Glass Jacketed Vessel from Mumbai, Maharashtra. The vessel can be availed from us at minimal costs. Introduction : All GLASS Jacketed vessels manufactured by Garg Scientific Instruments are based on the flat flange system. This standardized flange system provided customers with a comprehensive range of accessories and replacement parts. The O-ring groove in the vessel's flange facilitates simple safe mounting of the vessel with the Associated lid.The GLASS Jacketed vessels are available as standard in three versions. Vessels without outlet and vessels with outlet. The outlet can be either a spherical ground joints our valve. In the range of temper able GLASS Jacketed vessels various joints for coolants are possible In addition to the classic GLASS olive joints; threaded GLASS joints with removable plastic olive joints DN1S and DN25 are available. All GLASS Jacketed vessels including the standard types are manufacturers to customer’s orders. Therefore, modifications to joints or flanges are usually offered at no extra cost. In case where GLASS Jacketed vessels have been designated with a particular over pressure, the difference in temperature in the GLASS wall may not exceed 20o C. All GLASS Jacketed vessels are subjected to individual pressure tests at the works following production. The GLASS Jacketed vessels are subjected to 1, 5 of nominal pressure at room temperature. Versions other than those the versions described here are always available. On request we can supply you with a professional overview of our products per CAD drawings. Types : Types of Outlets for Glass Jacketed Flask, Plain Vessel Cylindrical, Plain vessel Cylindrical with “L” Valve, Plain vessel Cylindrical with “J” Valve, Heatable Glass Jacketed vessel with Thermal Jacket Connection GL 18-Olive, Heatable Glass Jacketed vessel with Thermal Jacket Connection DN15-Flange, Heatable GlassJacketed vessel with Thermal Jackect Connection GL – 18 Olive “J” Type, Heatable Glass Jacketed vessel with Thermal Jacket Connection DN15-Flange “J” Type, Heatable Glass Jacketed vessel with Thermal Jacket Connection GL 18-Olive & “L” Valve, Heatable Glass Jacketed vessel with Thermal Jacket Connection DN15-Flange & “L” Valve, Heatable Glass Jacketed vessel with Thermal Jacket Connection GL 18-Olive & Drain S40 Joint, Heatable Glass Jacketed vessel with Thermal Jacket Connection DN15-Flange & Drain S40 Joint, Heatable Glass Jacketed vessel with Flat Bottom & Thermal Jacket Connection GL 18-Olive, Heatable Glass Jacketed vessel with Flat Bottom & Thermal Jacket Connection DN15-Flange & Drain S40 Joint, Heatable Glass Jacketed vessel, Vacuum Jacket with Thermal Jacket Connection DN15-Flange & “J” Valve, Lid For Glass Jacketed, Stirrers.

...more

Glass Heat Exchanger

We make available our Glass Heat Exchanger in two categories, namely Coil type and Shell & Tube type. It can be used for variety of applications such as condensation, cooling, heating, boiling and suitable combinations of the above. Moreover, the selection of equipment depends upon the type of application, heat load, availability of heating/cooling media and various other factors. Moreover, our Glass Heat Exchanger is reasonably priced. Functioning :In all types of glass Heat Exchangers the heat transfer is through the wall of the glass tube. The heat transfer co-efficient can be of a moderate order because of low wall thickness. With 1.5 mm thick walled tubes, the wall heat transfer co-efficient is about 725 Kcals/hr m2oC and we can obtain an overall heat transfer co-efficient for steam condensation with water-cooling as about 550 Kcals/hr m2oC. The allowable pressure inside the tubes can be vacuum to 3 kg/cm2 while that on the domes as well as on the shell depends upon the size of the shell corresponding to the values mentioned in technical specifications. The Heat Exchangers can safely be used up to 150oC with the limitations of thermal shock up to 120oC and temperature gradient across the wall less than 50oC. The shell side pressures on metallic shell & tube heat exchangers can be as high as 2.5 kg/cm. For higher pressure requirement up to 4 kg/cm2 , the PTFE tube sheets need redesigning and can be made on special request.Available Types : Coil Condensers Product Coolers Immersion Heaters Boilers Coil Condensers, InformationComposed completely of glass, coil heat exchangers are typically used as vapor condensers and liquid coolers. They are usually designed and installed as an integral part of a vertical column. To provide a reliable corrosion resistant internal seal, the coil battery is sealed to the jacket, creating a single unit. Boilers and immersion heaters are also available in this all-glass coil design.Other DesignsWe also offer glass cascade coolers, bayonet and jacketed-type heat exchangers. For further information on these special application models, please contact us.Technical Data Heat Transfer in CondensersThe heat transferred in coil condensers con be considered generally as 55 Btu/hr-ft2-oF for any unit. This figure may vary from 10 to 72 Btu/hr-ft2-oF depending on the fluids involved and the operating conditions.

...more

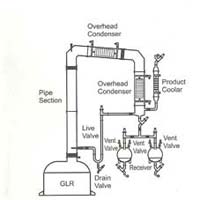

Distillation Overhead Assembly

The company is the known Manufacturer, Exporter & Supplier of durable and high-performance Distillation Overhead Assembly. The design and features of our assembly can be built according to the requirements of the clients. Our distillation overhead assembly for GLR can be obtained at reasonable price from us. We make use of glass lined reactors instead of glass reactors, especially when the scale of operation is large and relatively high pressure steam is to be used as heating media. Sometimes, assemblies like simple distillation unit, fractional distillation unit and others are also installed above our glass lined reactors. The basic features of such assemblies remain the same but glass shell & tube heat exchanger is preferred due to large scale operation.

...more

Industrial Couplings

We are renowned for offering high quality Industrial Couplings for use in various industries. Though present in various models, sizes and shapes, clients have the option to customize their order of couplings according to their industrial requirement. That is why we are a prominent Manufacturer, Supplier and Exporter of Industrial Couplings from Mumbai, Maharashtra.

...more

Column Components

Our company has carved a niche as the Manufacturer, Supplier and Exporter of Column Components from Mumbai, Maharashtra. Fabricated using advanced machinery and accurate molds, our Column Components are preferred by various research establishments. Clients from all over the world can order bulk quantities of Column Components from us at affordable rates. Introduction Like their pipeline counterparts, Borosilicate glass column components find universal application throughout the world’s chemical, pharmaceutical, food and drink and allied industries where the advantage of using glass as a basis for the construction of complete process systems have long been recognized: With almost universal resistance to corrosion, a long service life is guaranteed and maintenance is kept to a minimum. Their transparency permits visual monitoring of the process at all times. Being inert, the risk of contamination is negligible. Smooth surfaces allow easy cleaning and sterilization and prevent the build-up of solid on the inner walls. In many unit operations such as reaction, extraction and absorption, the transparency factor of glass column components is a particular advantage. As an example, color changes in reaction processes are easily monitored, droplet separation in extraction processes can be observed unhindered and constant visual monitoring of hydraulic performance in packed columns is possible.Column components are available from DN 80 to DN 450 with a smaller range of precision bore components available from DN 25 to DN 150 for specific applications where close internal tolerances are essential.The complete range of column components is described on the following pages. All column components have standard flat buttress end connections. Further details of theses are provided in section: Technical Information.For standard flat buttress end connections from DN25 to DN300, it is possible to achieve a 3° deflection in the joint by using a flexible gasket. Details of these and all other couplings and gasket can be found in section Couplings. DN refers to the nominal bore. Unless otherwise stated all dimensions are given in mm.For permissible operating conditions, unless otherwise stated in the individual description, please see section Technical Information. Applications of internalsColumns used for absorption and extraction processes can be fitted with many different internals such as packed beds, structured packing and sieve or bubble-cap trays. The typical operating characteristics, as well as the recommended and possible areas of application for each of these internals, are detailed in this section: the processes being limited to gas/liquid operation in the form of rectification and absorption processes.Packed beds or structure packing are used to create the surface required for mass transfer by increasing the area of contact at the surface of the liquid when it flows over the internals as a film. Irregular packed beds have a relatively high-pressure drop. Figure 1 shows the pressure drop for ceramic saddles. A very significant reduction in pressure drop, particularly in regard to vacuum rectification, can be achieved by the introduction of structured packing. Figure 2, for example shows the pressure drop values for SULZERKERAPAK. A clear reduction in pressure drop is discernible here. Applications of internals In plate columns the boundary surface for mass transfer is created by the liquid phase flowing across the trays being penetrated by the gas or vapour rising from the plate below. The main distinctions here are between bubble cap trays and sieve trays. Plate columns have higher-pressure drop then packed columns. To illustrate this, Figure 3 on the previous page shows the pressure drop of the buyer low-rise tray. The pressure drop of the tray is about the same as for 1 meter packing of 25mm ceramic saddles.The suitability of internals to a particular process is really determined by the process conditions in each case. If a low-pressure drop is required, then structured packing are the main ones to choose. In all other cases the permissible operating range of the various internals for a particular application is the determining factor. Packed and plate columns have different operating ranges as a result of the different type of boundary surface creation. The terms operating range here refers to the range of gas and liquid flows within which problem-free operating of the column is possible. Figure 4 shows typicall load characteristics of a packed column with the operating range shaded. This is mainly limited by the so-called upper load limit, designated by flooding, against higher flow. The lower load limit designated by minimum wetting stems from the requirements that the packing has to have an even film of liquid to achieve the desired separation. It can also be seen from Figure 4 that it is possible to individual cases, however, the achievable separation effect should be checked.Plate columns have different operating characteristics. As the load characteristics in Figure 5 show, several factors limiting the operating range have to be taken into consideration with this design. It must be emphasized in particular that turndown of the liquid load is much greater for the plate column.

...more

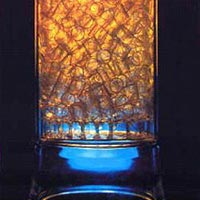

Sight Glasses

With an experience of more than 30 years, we are recognized as a major Manufacturer, Supplier and Exporter of Sight Glasses from Mumbai, Maharashtra. Made from high grade glass, our product has attributes like heat and chemical resistance, great durability, low thermal expansion, etc. Buyers can avail bulk quantities of Sight Glasses from us at competitive prices Introduction :Sight glass is the only item which has nothing to do with glass pipelines. This is used to check inline flow of chemicals or liquids in horizontal as well as vertical installation. It is constructed to give full view from any angle to save time and energy. It is also made a multi-purpose to achieve high standards of economy. Since one sight glass can be used with MS/rubber/lead glasslined etc. It leads to less inventory. One sight glass consists of a glass pipe section, one metal frame, one pair of teflon bush and washers.( Metal frame can be made of MS/SS 304/SS 316)Glass pipe section is made from borosilicate glass which is highly heat resistant and has low thermal expansion and excellent chemical durability. This pipe section is flared at both ends to increase its compressive strength as well as to ensure of leak proof fitting in metal frame.Metal frame is of mild steel, zinc plated or resin powder coated, as desired, to eliminate the risk of corrosion. Both flanges of frame are welded with stud so that the stresses and vibrations of line, where it is to be fitted, would not transfer to glass pipe section. Its chuck nut system keeps the glass pipe section in compression and make it easy to replace the same.Teflon bushes are provided on both the sides of glass pipe section in a way that flowing liquid/chemical would not be in contact with any metallic part of the sight glass. Further teflon washers are provided to use as gasket on both sides at the time of fitting.Sight glasses can be supplied with the flanges frilled as per customers requirements. However as it is found that most of our clients using sight glasses demand ASA 150 table flanges. We use to keep ASA 150 table glasses ready in stock.

...more

Shell and Tube Heat Exchanger

We are a renowned name as the Manufacturer, Supplier and Exporter of Shell and Tube Heat Exchanger based in Mumbai, Maharashtra. The Shell and Tube Heat Exchanger we provide is widely appreciated for their sturdy construction, robust designs and high precision. We can fulfil the bulk demands of exchanger by our clients easily. SHELL AND TUBE Heat Exchangers, they can be used for variety of applications, namely, Condensation, Cooling, Heating, Boiling and suitable combinations of the above. The selection of equipment depends upon the type of application, heat load, availability of heating/cooling media etc. In all types of glass Heat Exchangers the heat transfer is through the wall of the glass tube. The heat transfer co-efficient can be of a moderate order because of low wall thickness. With 1.5 mm thick walled tubes, the wall heat transfer co-efficient is about 725 Kcals/hr m2 oC and we can obtain an overall heat transfer co-efficient for steam condensation with water-cooling as about 550 Kcals/hr m2 oC. The allowable pressure inside the tubes can be vacuum to 3 kg/cm2 while that on the domes as well as on the shell depends upon the size of the shell corresponding to the values mentioned in Technical Specifications. The Heat Exchangers can safely be used up to 150o C with the limitations of Thermal Shock up to 120o C and temperature gradient across the wall less than 50o C. The shell side pressures on Metallic Shell & Tube heat exchangers can be as high as 2.5 kg/cm. For higher pressure requirement up to 4 kg/cm2, the PTFE tube sheets need redesigning and can be made on special request Range of the Models : Shell & Tube Heat Exchangers Type RGM Shell & Tube Heat Exchangers Type RGG Shell & Tube Heat Exchangers Type RMG

...more

hcl gas generator

We are an eminent Manufacturer, Supplier and Exporter of HCL Gas Generator from Mumbai, Maharashtra. Fabricated using high-grade components, our generator are known for their efficient performance and compact design. Our large distribution network ensures that customers from all over the world receive their order of HCL Gas Generator quickly and well packed. Azeotropic Boiling Route : Commercial hydrochloric acid is available in the market as 30% aqueous solution and is widely used in industry in large quantities. But for certain applications e.g. in bulk drug/pharmaceutical industry HCL gas is required in gaseous form. Such users generate anhydrous HCL from commerical grade for their captive consumption. Several methods have been adopted and genertion through BOILING ROUTE is also a reliable technique. Salient features Operational reliability Available in wide range capacities - from 10kg to 200kg/hr of dry HCL. Except commercial hydrochloric acid, no other raw-material is required. The spent acid about 21% HCL usually finds use for captive consumption. Capable of operating from 25-100% . Ease of installation. Negligible pressure drop.

...more

Reaction Distillation Unit

We are a well know Manufacturer, Supplier and Exporter of Reaction Distillation Unit from Mumbai, Maharashtra. The Reaction Distillation Unit offered by us is designed to suit the customer’s requirement and can work at different atmospheric pressures. We ensure the satisfaction of customers by timely delivering their order of Reaction Distillation Unit. This unit is designed for the combat ion veseratile recation/ distillation or combination for polt plant work. This has the flexibility of working under atmospheric and vacuum.Standard Unit has a reaction vessel fitted in a metal heating/cooling bath for heating and cooling purpose of Fluid as media. The standard system is equipped with stirrer heaving mechanical seal, a packed column at the side neck of the vessel , reflux divider, coil type condenser or receiver system having product, cooler, vent, drain and vacuum valve, option of speed variation by mechanical variator or electronic variator can be provided. Product cooler, vent/vacuum valve and drain valve are the part of Receiver system. This unit is available in 10 ltr., 20 ltr., 50 ltr,. 100 ltr., 200 ltr., and 300 ltr. Capacity with spherical reactor. The optional material that can add as per your requirements are as follow:- Heating mantel. In place of jacketed heating/cooling bath MS PTFE lined stirrer in place of glass stirrer. Simple drain valve.

...more

Fractional Distillation Unit

We are a premium Manufacturer, Supplier and Exporter of Fractional Distillation Unit from Mumbai, Maharashtra. Available in various vessel sizes, clients can also customize the design of the unit according to their industrial requirements. We are capable of delivering bulk orders of Fractional Distillation Unit to our clients within promised time. This unit is main purpose is for distillation and fraction under vacuum and atmospheric pressure. Standard Items that are used in this unit are distillation vessel fitted in metal bath of heating/cooling with a packed column above reflux divider and coil type condenser below are fitted on the packed column. Condensed material is taken back to vessel or to the receiver via product cooler. This unit is available in 10 ltr., 20 ltr., 50 ltr,. 100 ltr., 200 ltr., and 300 ltr. Capacity with spherical reactor The optional material that can add as per your requirements are as follow : Heating mantel. In place of jacketed heating/cooling bath. Simple drain valve.

...moreBe first to Rate

Rate ThisOpening Hours