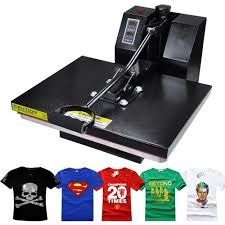

T Shirt Printing Machine

10,000 Per Units

textile printing machine

Get Price Quote

Tauschen Brand Printer is equipped with latest printing technology which applies color to fabric in definite patterns or designs. Tauschen provides you best quality Textile printing machines for Sari printing, T-shirt printing and coating padding. The machine is made with preapproved standard quality components availed from relevant vendors who work according to the set industrial rules. Features: Good resolution Good speed Best quality pictures

Best Deals from Garment Printing Machine

Print Fabric

Get Price Quote

Traditional Hand Block Printed Fabric offered features smooth fabric quality as well as come with elegant designs, intricate patterns so as to meet the demands of designer appearance. Further, the beautiful and exclusive block print designs of these fabric choices also makes them preferred choices of the customers.

polyester printing machine

Get Price Quote

WebFlex Machines is popular manufacture and exporter of Polyester Film Printing Machine. The robust construction and smooth execution of jobs are some of the salient features of this machine. UNWIND Unit: Polyester Film Printing Machine unwind unit has specially designed ball bearing assembly to accept standard cores and this is done by incorporating a shaft with tapered reel cones. We have arranged for lateral displacement with mechanical clutch at crucial points for easy operations and also to maintain perfect web tension adequate idle rollers are provided.

digital textile printing machine

Get Price Quote

Kyocera printhead with excellent durability Maximum 140m²hr productivity Capable of printing variable clothes such as cotton, silk, linen, rayon and polyester High capacity dryer for fast printing Various safety sensors for operators (including obstacle detection, wrinkleThe DGI FD-1904 Fabrijet Printer is designed for high speed textile printing, sampling and mass production printing. FD 1904 operates at a max speed of 200 m2hr and delivers a production mode of 115 m2hr. Used is a Kyocera 2,656 nozzle printhead (4 heads) for excellent durability. detection and Fabric end detection)

Digital Garment Printing Machine

Get Price Quote

Digital garment printing machine is designed for high speed textile printing, mass production printing capable of achieving 100 linear metres per hour. FD 1908 delivers a speed of 200 m2hr with a max print width of 1,850 mm and a max media width of 1,900mm. Used is a Kyocera printhead (8 heads) for excellent durability.

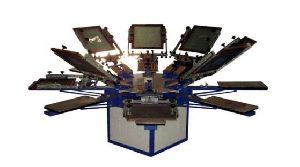

textile printing machine

Get Price Quote

We are engaged in offering to our client premium Textile printing Machines These are fabricated using high grade material sourced from market trusted vendors. Our precision-engineered machines offered by us are widely appreciated for cost-efficient printing on different type of fabrics. We offer these machines in varied specifications in varied specifications and size to match the application specific requirements of the clients. The machines offered by us are widely appreciated for the following factors Scree Size : 22" Max

Polyester Film Printing Machine

Get Price Quote

WebFlex Machines is popular manufacture and exporter of Polyester Film Printing Machine. The robust construction and smooth execution of jobs are some of the salient features of this machine. UNWIND Unit: Polyester Film Printing Machine unwind unit has specially designed ball bearing assembly to accept standard cores and this is done by incorporating a shaft with tapered reel cones. We have arranged for lateral displacement with mechanical clutch at crucial points for easy operations and also to maintain perfect web tension adequate idle rollers are provided. MOTORISED REGISTER CONTROLS: In order to obtain fine registration of multi-colour prints at operational speeds we have provided Mechanical devices at operating side, which helps during cross as well as lengthwise registration. Similarly compensating roll moving up and down on linear screw system with servo motor is used for longitudinal registration or alternatively for longitudinal registration we also provide SS roll cantilevered by screw and slo syn motor and this is easily operated due to individual panel board which has individual push button controls for smooth and easy operations of the unit. Based on customer’s requirement we provide pneumatic or manual Rubber Roll Impression. Laminated Foil Printing Unit: This laminated foil printing unit is a cylindrical unit and includes removable impression rollers and doctor blade. The roller can be removed for changing, working and making it ready to use. Similarly doctor blade can be removed to sharpen and replace blades. The position and angle can be adjusted of the oscillating doctor’s knife as suitable to the diameter of the printing cylinders. We have fitted laminated foil printing unit on low friction gun metal bushing with mechanical oscillation off the gear box drive. All the units of blades have been made ready with devices for oscillation and change of angles of blade are designed to suit diameter of the cylinders. GEAR BOX: Polyester Film Printing Machine's Gear Box is spiral bevel reduction/oil immersed and fixed at the unit side frame along the machine. It has a mechanical drive for alternate transversal movement of the doctor blade. The adjustable stroke of doctor’s blade is of +/- 9mm. The special feature of Polyester Film Printing Machine’s gear box is the reverse printing facility, we have provided at few stations. REWIND UNIT: In the rewind unit printed web is coiled around the shaft made from steel alloy on a paper core, which is locked by tapered cones provided in the shaft and mounted on ball bearing assembly. Friction clutch mechanical assembly drives rewind shaft and controls the web tension and this enables perfect and tight rewinding without any stretch of the film.

textile printing machine

Get Price Quote

The ND-4 uses an individual direct drive to each screen, due to this, the blanket and screen heads are synchronised precisely. Lateral and diagonal settings and magnet pressure can be set on individual printing heads and stored in memory.

T Shirt Printer

Get Price Quote

We are offering t shirt printer. Technical data: printer model hj-8420 printing methods c m y k (+ w w w w ) c m y k + lc lm lk llk c m y k + c m y k printing precision 720dpi/ 1440dpi/ 2880 dpi printing speed a4/ draft mode 19.5s a4/ quality mode 40.5s a4/ precision mode 1min40s printhead cleaning method auto ink supply system 200ml/ 8color ink cartridge printhead protection infrared sensors rack sprinklers automatic adjustment system printable size (max.) 420mm * 600mm print object height detection intelligent sense dual-detection system media thickness(max.) 10cm data transmission interface usb 2.0 power ac 220v/110 ± 10, 50hz-60hz, power ≤ 350w operating environment temperature: 18~32℃ humidity: 40~70% output software hong-jet-softrip weight 110 kg printer dimension 850 * 810 * 450 mm ( l * w * h) package dimension 1040 * 1020 * 840 mm ( l * w * h)

T Shirt Printing Machine

Get Price Quote

T Shirt Printing Machine, emboss machine, Embossing Machine

Rotary Flat Bed Trendy Fabric Printing Services

Get Price Quote

Rotary Flat Bed Trendy Fabric Printing Services, Mild Garment Washing Services

Color Ribbon Hot Printing Machine

Get Price Quote

Color Ribbon Hot Printing Machine, Ring Foiling Machine

textile rotary printing machine

Get Price Quote

textile rotary printing machine, dew drop machine, Fabric Printing Machine

textile printing machine

Get Price Quote

textile printing machine, Heat Press Machine

T-Shirt Printing Machine

Get Price Quote

T-Shirt Printing Machine, Semi Automatic Multi Color Lanyard Printing Machine

cap printing machine

Get Price Quote

cap printing machine, Textile Machines, textile printing machinery

Garment Printing

Get Price Quote

Garment Printing, sublimation printing