Workshop Vehicle

Application Field Work shop cabin on wheels.

Wind Turbine Parts for Wind World India Ltd

A set has 3 components of Carbon Steel of about 4m diameter weight 7.3 tons Fabrication of a combination of Prismatic and cylindrical sections to accuracies of +/- 1mm over 4m length As these structures are prone to heavy distortion during welding, special fixtures are developed to control distortion Extensive use of automatic welding processes – FCAW and SAW SPM for drilling holes on disc rotor, with multi spindle drilling

...more

Transfer Magazine (STIB) 220 MW

Used for transferring new fuel bundles from NFM to Fueling machine & transferring spent fuel back to Shuttle Station Material : SS 304 Size: 1.2 meter x 600 mm x 3.2 meter Weight: 5 Tons / assembly Critical requirements: Precision distortion controlled fabrication Very accurate Linear recirculating roller bearing made from AISI 440C Challenges: 200 precision components per assembly Machining of components with tolerances in the range 10 to 20 microns Optical alignment of magazine tubes within 100 microns Development of Linear recirculating roller bearings

...more

Toroidal Vacuum Vessel

What is Toroidal Vacuum Vessel Its High vacuum vessel with vacuum requirement of 1 x 10-9 Torr (Highest ever made in GPE) Material of construction : SS 304L Size Weight Critical Aspect of : Its High vacuum vessel with vacuum requirement of 1 x 10-9 Torr (Highest ever made in GPE) Material of construction is SS 304L Total 111 nos. of ports on Toroidal vessel All the weld joints tested for helium leak testing at rate of less than 1 x 10-9 Mbar L/s Vessel is undergone various cleaning procedures like buffing, Degreasing, Electro- polishing and ultrasonic cleaning to achieve the surface finish of 1 micron and achieve highest cleanliness to reduce out gassing effect. ID of vacuum vessel is electro-polished to improve surface finish to less than 1 micron All the weld joints tested for helium leak testing at rate of less than 1 x 10-9 mbar L/s ID of vacuum vessel is electro-polished to improve surface finish to less than 1 micron. Total 111 nos. of ports on Toroidal vessel

...more

Stand Pipe Thimble Assemblies 220 MW

Control Rods move within SPTA. Connects Drive Mechanisms to nuclear reactor core Each reactor requires 81 assemblies Material: SS 304 Sizes: 150 to 300 mm diameter and 3 meter to 6 meter in length Weight: 18 tons per reactor Critical requirements: Precision machined parts for accurate precise assembly at site Challenges: Ovality within 50 to 150 microns Straightness within 100 microns per 300 mm, maximum 1 mm over 6 meter length

...more

Shuttle Transfer Stations 500 MW

Used for moving spent nuclear fuel bundles from reactor core to under water storage area Material: SS 304L Size:2 meter diameter x 5.5 meter height Weight: 8 ton Critical Requirements : High-pressure leak proof water hydraulic cylinders Equipment works under heavy water Service life 30 years Challenges : Optical alignment of guide ways to ensure movement within 200 microns over 4.5 meter Aligning guide rods within 100 microns for 5 meter length

...more

Shuttle Station (STIB) 220 MW

Used for transferring spent fuel bundles from Transfer Magazine to discharge area. Two assemblies required per reactor Material: SS 304 Size: 1.2 meter diameter, 4 meter long Weight: about 3 Tons / assembly Critical requirements: Precision distortion controlled SS shell fabrication Precision alignment of fuel ports Challenges : Realization of 150 precision components having tolerances 10-20 microns Optical alignment of carriage guides with fuel ports

...more

Rotating Plugs

Used for aligning fueling arm with fuel channels in Fast Breeder reactor Material: A48 P2 plates, forgings Size: 7 meter diameter 2.5 meter height Weight: 120 tons Critical Requirement: Position accuracy within 0.5 mm Challenges : Procurement of A48 P2 plates, rings and forgings to required dimensions Large precision fabrication of 7 meter diameter shells, ovality control within 3mm, gap between two shells within 20 mm VTL machining with temperature correction, flatness 150 microns Thermocouples installation with He-leak test & RT Thermocouples installation with He-leak test & RT Development of custom built Gear boxes designed for seismic conditions Manufacturing of Turntable Slewing bearings, 7 meter and 4.7 meter diameter as per IGCAR design Teflon coating proving and application on rings prior to finish machining Assembly and functional testing to prove position accuracy

...more

Primary Sodium Pump Shaft, PFBR for BHAVINI through KBL

Main shaft of Primary Circuit Sodium Pump for Prototype Fast Breeder Reactor. Material: SS Size: 700 mm diameter x 11 meter long Critical Requirement: Position accuracy within 0.5 mm Made from three parts, two solid forgings about 3.5 meters long and one hollow forged pipe about 5 meters long, at the centre Shaft to be dynamically balanced at 600 rpm Challenges : Reconditioning and calibration of lathe to deliver 50 microns over 12 meter length. Development of line boring 650 mm ID x 5 meter long and honing of centre piece Optical alignment and welding of 3 pieces together within 2 mm over 12 meter length. Development of machining process, parameters to deliver accuracy of 50 microns over entire 12 meter length. Bearing diameter grinding

...more

Preventing Maintenance Contract

Benefits of the Preventing Maintenance Contract(PMC) Helps you in minimizing the maintenance & operation cost with minimum downtime of your Godrej machine by planned and proper periodic maintenance. You can avail concessional rate for spares which are required to be ordered and kept in stock. Concessional service charges compared to one time call. Attention by skilled and trained technicians who will attend to your Godrej machine, suggest timely remedial measures and recommend suitable spare parts to be procured if any. This will help you in proper maintenance of your machine at minimal cost. Preventive Maintenance Schedule For Godrej Power Press & Mechanical Press Brake Lubrication Flush out and clean the lubricating system and refill with fresh oil Check the oil lines, oil holes and oil grooves for clogging up. Drain the oil from the enclosed gear box and fill fresh oil to the specified level. General Left-to-right and front-to-back level of the machine and correct, if required. Clearance in the gib guides if excessive, adjust. Adjust back gauge driving and indicator chains. Adjust belts for tightness. Condition of brake liner and brake adjustment. Tripping linkage/EPT System. Counter balance assembly. Clutch assembly for liner wear and replace liner if required. Electrical contacts and connections and rectify where required. P B tooling for condition & recommend. Productivity improvement necessity and recommend any accessories / upgrading. Preventive Maintenance Schedule For Godrej Mechanical Shear Lubrication Flush out and clean the lubricating system and refill with fresh oil Check the oil lines, oil holes and oil grooves for clogging up. Drain the oil from the enclosed gear box and fill fresh oil to the specified level. Motor bearings (with grease) Drain and refill oil in hold down box. General Check Left-to-right and front-to-back level of the machine and correct, if required. Clearance in the gib guides if excessive, adjust. Adjust back gauge driving and indicator chains. Adjust belts for tightness. Condition of brake liner and brake adjustment. Knife clearance and reset, if required. Tripping linkage. Counter balance assemblies Hold down units for leakage Electrical contacts and connections and rectify where required. Blade sharpness and recommend grinding / spare blade. Terms & Conditions For PMC Duration of this agreement will be ONE YEAR w.e.f. date of receiving full earnest money. Machines are expected to be in good working condition while accepting the contract. In case there is a breakdown then the machine will be attended first at cost and the PMC will be separately discussed. In order to ensure minimum downtime the customer is advised to order and stock all the required spares for Preventive Maintenance Contract (PMC) in advance. The list of spares is available on the net for standard models or can be requested. In any case our representative will hand over such list while finalizing the contract. All recommended lubricants, oils, tools, etc., are in the scope of the customer. In addition, we request the customer to provide basic help to our technician like the material handling equipment and semiskilled labour etc. In order to get the best results, it is obvious that the customer should carry out the daily maintenance as per the guidelines given in manual. Preventive maintenance shall be carried out as per the laid down format enclosed. However we will be open to carry out any job over and above the scope of preventive maintenance at an extra cost. The customer is expected to keep available the said machine / s or other facilities. In case of any difficulty the date should be changed in advance by mutual consent. Alternatively the visit will be treated as completed. It is possible that machine covered under the plan can breakdown. Our services will in any case be available in such event at an extra cost. We can also undertake overhaul of subassemblies / assemblies at an extra cost. We shall be entitled to terminate the agreement in the event of change of ownership or location of the said machine. Either party shall entitled to terminate the agreement at any time giving one month’s advance notice, and the customer shall be entitled to refund of the advance on pro-rata basis for the unexpired period of the agreement. If prior to offering the machine for PMC the machine is offered for overhauling, a lump sum quotation towards service charges will be offered with concessional service charges as above. Fill the below mentioned form for Preventive Maintenance Contract (PMC)

...more

precision engineering equipment

Godrej Precision Engineering Division delivers customized solutions meeting exacting quality requirements in the high technology domain. Broadly Godrej Precision Engineering business can be classified as:Equipment for Nuclear Power Generating plants of Nuclear Power Corporation Ltd : Godrej Precision Engineering is qualified for several fuel handling and positioning systems for the Power Plants and competes for orders from NPCIL.Equipment for Indian Defence : Largely contributed for 1st time developmental projects for Indian Defence systems.Customized equipment : Large precision fabricated and machined equipment for Gas & Steam Turbines, Turrets for Ladles in Steel industry for the continuous casting process.Manufacture of Wind Turbine Generator Parts : These are precision fabricated and machined to close tolerances. The present focus is to produce the large parts needed for gearless wind turbines.Precision Engineering Services : Offering lifetime support service for equipment and system supplied by PES

...more

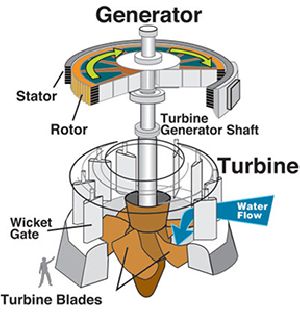

Oil Header Assembly of Kaplan turbine

Application System through which pressurized oil enters from top end of turbine and rotates the runner. It includes series of pipe (total size 34m) passing through shaft center Scope include Raw material procurement, fabrication, stress relieving, machining, hydro testing with oil Critical requirement Precision fabrication Accurate & Precise machining of pipe Hydro testing at pressure 240 bars Developed first time India for customer

...more

Object Laying Equipment

Used to lay, bury, camouflage, Anti-Tank bar mines across the plain, desert and semi-desert terrain. The system is built on a 8x8 TATRA V 815 vehicle Capacity to carry maximum 507 mines at a time Key Features : First time development in India for Army. Power supply system to produce required power of 138HP. GPS system having accuracy 20 mm, to record position of each mine layed. Automatic dispensing arming, trenching and camouflage system. Designed to work at -15° to +50 ° Celsius. Challenges : Space constraints – Accommodating sub-assembliesto store and dispense 507 mines in a fully automated mode, with space for seating for two operators. Accommodation of DG for Power supply. Making the system highly reliable and robust, to handle ammunitions in a very dusty environment. Modification of the engine chassis to suit our requirements.. Short deploying time - Retaining the mobility of the system (departure angle, belly angle) even while enabling the system to become mission ready in couple of minutes. Laying mines at 10 seconds interval, continuously. Electrical: Harnessing the entire wiring. Junction box of DG Cable laying and ducting. Designing and development of GPS system with 20 mm accuracy

...more

New Fuel Magazine (STIB) 220 MW

Used for handling new nuclear fuel bundles from storage area to Transfer magazine, Two units per reactor Material: SS 304 Size :1.4 meter x 1.2 meter x 3 meter Weight: 3 Tons / assembly Critical requirements: Precision distortion controlled fabrication, precision alignment of all tubes with two fuel ports Challenges: 400 precision components per assembly Machining of components with tolerances in the range 5 to 10 microns Optical alignment of magazine tubes within 100 microns

...more

Mobile SAR for Defence Lab

Application System used for microwave mapping of large objects by Defence Laboratory, Jodhpur. Key Features : Product Development from concept. Positional accuracy and movement, with repeatability in 0.5 mm. Movement : X axis 10 meters Y axis 3.0 meter Z axis rotation 120 – degree.

...more

Mobile Replenishment Vehicle

Application Replenish Mobile Launchers with loaded missile containers and remove spent containers from launchers. Key Features : System mounted on TATRA 12x12, used for transporting missile containers. Autonomous operation with crane mounted on vehicle.. Removes spent containers from launcher, loads launcher with new containers. Loads spent containers on vehicle and transports back spent containers to depot. System maintains Missiles at desired temperature during transit

...more

Mobile Autonomous Launcher

Application Vehicle mounted Launcher for 3 BrahMos missiles, for autonomous - self sufficient launch. Key Features : Operation in extreme conditions -40 to +55 deg C Mechanical system with Low alloy high strength material, requiring special welding process, distortion control. High flow hydraulics Variable speed Power-Supply. Electrical controls, Software development for Auto-Launch-cycle. Complete System integration of subsystemsMechanical, Hydraulic, Electrical Controls, Power Supply, A/C, Thermal conditioning, Equipment shelter with Nuclear-Biological filters. Prompt Site Support for Launcher for Joint Receipt Inspection of Defence forces for induction. After sales service / AMC.

...more

Microtron Magnet Assembly

What is Microtron Microtron Magnet Assembly is used to generate and energize electrons & photons Material of construction : Extra Ferrite Electric Steel (EFE) SS 316 LN Size Weight Critical Aspect of Microtron: Welding of EFE required manufacturing of electrodes out of the material itself Magnet Pole, Yoke & Vacuum chamber all needed with demanding accuracies. Flatness of 0.03mm was achieved over a span of 1400mm Helium leak testing with leak rate less than 1 x 10-9 Mbar-litre per second 1

...more

Nuclear Reactor 500 MW Air Lock Doors

Air Lock Doors (main and for fuel) Material: SA516GR 70 Size: max 4500 x 5270 (ht) mm Weight : 16 Ton / 11 ton Heavy Fabrication, Machining & Assembly with door opening closing mechanisms Shop testing and demonstration

...more

machine tool service

Aging machines lead to increasing maintenance cost, unpredictable breakdowns and hence, a drop in performance. Instead of buying a new machine, reconditioning the old one provides almost original performance, is much faster and cost effective, and existing manpower can be utilised. We undertake complete reconditioning of old machines of local and imported makes, providing a 6 months warranty and the Godrej Preventive Maintenance Contract facility. Reconditioning involves complete re-building of the entire machine in order to restore complete functionality and accuracies of the equipment. Based on the scope of contract and your budget, the extent of re-furbishing can include the following: Complete strip down of the machine with a thorough inspection and replacement, if required, of all worn-out and failed parts with genuine parts. Machining, grinding, scraping of guides, tables and bearing bushes. Rewiring of the entire electricals. Retrofitting of modern hydraulic & CNC systems, if required Replacement of old lubrication system with a central, motorized, automatic, metered lubrication system with an electronic controller. Reassembly of the machine. Realignment of the machine to ensure the original accuracy. Final inspection, trials & painting of the machine. Inspection by customer & customer trials. Re-erection, re-commissioning, trials, training at site. Satisfied Customers M/s BEML, Bangalore M/s Balmer Lawrie, Sylvassa M/s BHEL, Bhopal M/s Kerala Electricals, Kerala M/s S.M.Rolling, Pune HAL, Bangalore M/s Supangita Engineers, Bangalore M/s Northern Railway, Amritsar M/s Vibha Enterprises, Mumbai M/s P.M. Techno Bangalore M/s Remi Motors, Mumbai Case 1. Imported Machine Customer Name: MICO, Nashik Make: Krupp 250 T Yr. of Mfg.: 1973 Type of M/c: Forging (H Frame) No. of Yrs used: 25 years Year of Reconditioning: 2000 Customer Name: Supangita Engineers, Bangalore Make: Godrej 100 T Press Type of Press: Forming / Blanking (C frame) Yr. of Mfg.: 1980 Type of M/c: Forging (H Frame) No. of Yrs used: 16 years Year of Reconditioning: 1996

...more

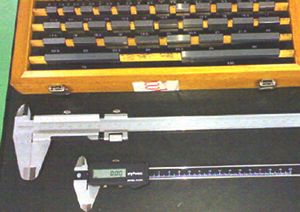

Machine Calibration

Scope of machine calibration: Calibrating all type of CNC machine with Laser Long slip gauges. Height master. Height gauge (Digital / Vernier) L. C.= O. 1 µm Glass scale Electronic level CMM CNC. (Linear Axes Only) L.C.=0.1,µm/1µm etc Universal Measuring Microscope Gauge Measuring Machine / Tool Centers. 1D, 2D, & 3D, etc. Linear Axis Profile Projector

...more

Ladle Turrets for Steel Industry Concast India Ltd

Used for movement of molten metal filled ladle from furnace to "Continuous Casting Machine" for higher output Material: carbon steel plates max thickness 130 mm and pipes Precision fabricated and machined material handling equipment Manufactured Turrets of both types – "with Lower & Lift", "without Lower & Lift", weighing from 15 tons to 75 tons Delivered more than 20 nos. to Concast India Ltd.

...more

instrument calibration

Objective: We are committed to complete the calibration of instruments within minimum possible time and without any complaint from our customer. Scope of instrument calibration: Visual inspection instrument for abnormalities. Zero Setting. Calibrating using master which are traceable to Primary Standards or National Standards. Servicing for minor deviations. Maintaining calibration record in Calibration software. Generating Calibration identification and Reports. Providing sticker for validation. Type of instrument calibration: Outside/Ball Micrometer. Vernier Calipers. Vernier Height gauge. Bore gauges. Depth Micrometers. Inside Micrometers. Measuring Pins. Bevel Protractor. Thread Plug Gauges. Surface Plate. Dial Gauges(Plunger/Lever). Heigh tMeasuring Instruments. (Micro hite,Trimos etc.)

...more

Glove Box

What is Glove Box {Glove Box (Qty 91 Nos.) Client DAE, (MRPU) } A Glove Box is a sealed container that is designed to allow one to manipulate objects where a separate atmosphere is desired Material of construction Size Weight Critical Aspect of Glove Box: Generally, there are two types of glove boxes exist One allows a person to work with hazardous substances, such as radioactive materials or infectious disease agents The other allows manipulation of substances that must be contained within a very high purity inert atmosphere such as argon or nitrogen

...more

LMM Calibration services, UMM Calibration services

UMM / LMM Calibration. NABL Accredited for UMM / LMM Machine Calibration with Laser Interferometer. Range of Calibration: 0- 1000 mm. Uncertainty of Measurement: 0.4 micron. Our Stength Unique Set up to Handle all types of Machines calibration for with different types of precision Laser Equipment. Competency to perform Calibration and Compensation in all types of Models and Make of Controllers. Our Equipment are with latest model and well handed to operate with Minimum uncertainty of Measurements. Team is competent to Interpret Results and guide Customer for Mechanical Error correction plan

...moreBe first to Rate

Rate ThisOpening Hours