Ayurvedic Herbs Grinding Machine

Get Price Quote

Wet Dal Grinder Machine

19,750 Per Piece

1 Piece (MOQ)

Best Deals from Grinding Machine

CNC Gear Grinding Machines

Get Price Quote

4 Inch Hikoki Angle Grinder Machine

3,000 - 4,000 Per piece

5 piece (MOQ)

Mild Steel Surface Grinding Machine

175,000 Per Piece

1 Piece (MOQ)

Granulator Recycling Shredder Machine

300,000 - 500,000 Per Piece

1 Piece (MOQ)

In today's world, waste management and recycling are critical for sustainable development. One of the key players in this process is the Granulator Recycling Shredder Machine. This powerful machine, such as those manufactured by SHREDALL, plays a pivotal role in recycling various waste materials, turning them into reusable products. A Granulator Recycling Shredder Machine, like the ones from SHREDALL, is a robust piece of equipment used in the recycling industry. It's designed to shred, crush, and granulate waste materials into smaller, manageable sizes. These machines are commonly used for processing materials such as plastic, metal, rubber, and paper. The Working of Granulator Recycling Shredder The working principle of a SHREDALL Granulator Recycling Shredder Machine involves a two-step process: shredding and granulating. Initially, the waste material is fed into the shredder, which reduces the material into smaller pieces. These shredded pieces are then transferred to the granulator, where they are further processed into tiny granules ready for recycling. Key Features Recycling not only benefits the environment but also has economic advantages. The materials processed by these machines can be sold to manufacturing industries, creating a profitable recycling business. Shredding Material The SHREDALL Granulator Recycling Shredder Machine efficiently processes various materials like plastic, metal, rubber, and paper. Its robust design and two-step process make it a key player in waste management and recycling. Shredding Machine Type The SHREDALL Granulator Recycling Shredder Machine, for instance, is an industrial shredder capable of processing a variety of materials for recycling purposes. It’s a robust and versatile machine, Dual Shaft, making it a valuable asset in waste management and recycling. Usage/Application The SHREDALL Granulator Recycling Shredder Machine is widely used in various sectors for its versatility. Its primary application is in waste management and recycling facilities, manufacturing industries to recycle waste materials into reusable resources, contributing to economic benefits and environmental sustainability. Capacity With a shredder from 100 kgs/hr to 500 kgs/hr, the machine is available for small, medium to large-scale operations. Automation Grade The Shredder Machine is fully automatic, which makes it easy to operate. Motor Power The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance. Country of Origin Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess. High Performance and Easy Installation The SHREDALLGranulator Recycling Shredder Machine is known for its high performance. It efficiently processes a variety of materials, ensuring optimal waste management and recycling. Despite its robust capabilities, the machine is designed for easy installation. This combination of high performance and ease of installation makes it a preferred choice in various sectors. Product Description The SHREDALL Granulator Recycling Shredder Machine is a high-performance, easy-to-install recycling solution. It’s designed to process a variety of materials, including plastic, metal, rubber, and paper, into smaller, manageable sizes. This robust machine is widely used in waste management and recycling facilities, contributing to environmental sustainability and economic benefits. Its efficient operation and easy installation make it a valuable asset in various sectors. Contact Us We are here to assist you. Feel free to contact us: Email: info@shredall.in +91 9820020754 Conclusion The SHREDALLGranulator Recycling Shredder Machine is a vital tool in our quest for a more sustainable future. Its ability to efficiently process waste materials into reusable resources makes it an invaluable asset in the recycling industry.

Commercial Spice Grinder Machine

500,000 Per Units

4 Jar Fortune Juicer Mixer Grinder Machine

2,385 Per

500 Piece (MOQ)

Granulator Machine

Get Price Quote

Oscillating Granulators, plays an important part in the process of granulation in tablet making as quality of tablet is determined by the virtue of the granules used for its compression Oscillating granulator can be used for wet and dry aspect of the granulation process.

Double Ended Eye Grinding Machine

Get Price Quote

Two Cup wheel arrangement with central lever force arrangement to clamp eye centre position. Both ends ground simultaneously Grinding Wheel Size: 12" x 4" x 4" Electric Motors: 3 HP x 2 nos Eye Grinding Capacity: 125 x 80 mmDimensions: 1.55 x 1.00 x 1.30 m Approx Weight: 1000 kgs .

Edge Floor Mini Surface Grinder

Get Price Quote

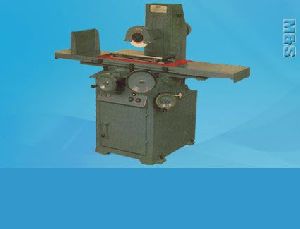

OMEGA Mechanical Surface Grinders

Get Price Quote

'OMEGA' Precision surface grinder are manufactured by incorporating modern techiques and ensure absolute vibration-free and nolseless working. The grinding accuracy of the machine are within easy reach of the opertor. The base is on heavy duty cast iron,which further ensures vibration-free service. All components are precisely manufactured to acheive maximum accuracy, which is invariably expected from a grinding machine.

Grinding Machine

Get Price Quote

We are a reputed Exporter and Supplier of Grinding Machine. Our Grinding Machines are sourced from the trusted vendors who manufacture their products as per international quality standards with high-grade components using the advanced technology. Our large assortment of Grinding Machine is acknowledged for its performance, robust construction and longer service life. Highlights : SturdyFlawless performanceLow maintenanceCompetitive price

Centreless Grinder

Get Price Quote

CENTRELESS GRINDER

Abrasive Belt Grinder Machine

Get Price Quote

Abrasive belt grinders are very versatile machine generally used by forge shops, press shops, ferrous & non ferrous foundries, fabrication shops, engineering industries, plastic & glass industries, rubber & leather industries, wood industries etc. The machine is fitted with excellent quality motor made from superior quality stamping and die cast rotors, which are dynamically balanced. This helps in minimizing vibrations and smooth running is achieved. Telescopic tendering arm for belt tensioning is provided. Machine is supplied complete with Abrasive Belt, Serrated Rubber Contact Wheel , Rotary Switch Starter and Safety Belt Guard. Machines are available in two Models i.e. Single ended and Double ended. And in bench type or pedestal type. Combination Multipurpose machine with abrasive belt assembly on one side and Grinding Wheel on other side is also provided The bench model machines are available from 1.0 HP to 5.0 HP capacity Kindly ask for details.

High Precision Vertical Double Disc Grinding Machine

1,000 - 5,000 Per piece

Plastic Small and Lower Output Crushing and Grinding Machine

50,000 - 2,000,000 Per piece

1 piece (MOQ)

Oscillating Granulator Milling Machine

Get Price Quote

Cylindrical Grinder

Get Price Quote

TOS BHU32 Cylindrical Grinder 1500X350 mm Cylindrical Grinder TOS BHU 32 used machine Used Machine TOS BHU 32 1500×350 mm TOS BHU 32 Cylindrical Grinder machine for sale Cylindrical Grinder TOS BHU 32 used machine, TOS BHU 32 Cylindrical Grinder, TOS BHU32 Cylindrical Grinder 1500X350 mm, Used Machine TOS BHU 32 1500x350 mm

WIRE EDGE GRINDING POINTING MACHINE.

475,000 Per UNITS

1 UNITS (MOQ)

This machine is to make Wire edge grinding pointing machines. Especially it makes all different types of wire edge grinding and pointing machines. We develop this model as per our customers given sample pic and dimensions or shape.. This is customized made to order machines. This machine is mechanical cam operated automatic machines. This machine video is visible to be seen on Youtube.. please see video link below