Ultrafine Mill

Get Price Quote

For almost 30 years, TQMC has being specializing in all facets of grinding mill design and maintenance. SCM series ultrafine mill is specially designed for super fine powder grinding. Now it’s growing more and more popular with its reliable technology and perfect after-sale services. Features High Output and low energy consumption High fineness and flexible adjustment Safe and Reliable Clean and environmental friendly

Colloid Mill

Get Price Quote

We are among the most trusted firms, engaged in manufacturing, supplying and exporting Colloid Mill Machine. Designed to perfection, our machines are manufactured using quality material and components that are sourced from the reliable vendors of the market. These machines are provided to customers in various models and sizes at market leading prices. Also, we provide tailor-made solution for Colloid Mill Machine as per clients needs.

Best Deals from Grinding Mill

Attritor Mill

Get Price Quote

We bring forth Attritor Mill that is also known as Stirred Ball Mill. The Attritor Mill that we deal in is made using steel of supreme quality and therefore renders longer service life as well. Besides, the Attritor Mill is highly suitable for wet or dry material blending as well as grinding.

Vertical Colloid Mill

Get Price Quote

Features : No castings are used for avoiding contamination problems. Coupling provided between motor shaft and rotor shaft for ease in maintenance —Vertical Model. oil seals between the motor and the processing chamber to prevent liquid going in the motor winding, resulting in the burning of the motor. Modified design of semi concave teeth in rotor and stator reduced motor HP and gives better performance in size reduction without damaging the product. Extended bearing housing specially designed to facilitate fine adjustments of bearing clearances or backlash to avoid metal to metal contact of rotor and stator. This unique design provides smooth and consistence all round performance and long life of rotor and stator. Three-way cock for draining and re-circulation of liquids provided as standard. Contact parts can be easily dismantled for cleaning. Special design facilitates adjustment of grinding gap by an exterior screw by means of handle even during operation. Flameproof motor and flameproof rotary switch can be provided on request at extra cost.

Devlieg Jig Mill

Get Price Quote

Hydraulic rock splitter machine c-12 Diesel Power pack

Get Price Quote

Vertical Planetary Ball Mill

Get Price Quote

Body & Glaze Preparation

Get Price Quote

Hdmi Splitter

Get Price Quote

The GefenToolBox 1:4 Splitter for HDMI 4K x 2K distributes one Ultra Hi-Def AV source to four Ultra HD displays simultaneously, without loss of quality or resolution. This product works with any Ultra Hi-Def source and supports resolutions up to 4K (3840 x 2160 @ 60Hz 4:2:0) and 4K Cinema (DCI) (4096 x 2160 @ 24 or 30Hz 4:4:4). It features Fast Switching Technology, and supports HDCP, Deep Color, 3DTV pass-through, and lossless audio formats such as Dolby® TrueHD and DTS-HD Master Audio™.

Nut Splitter

Get Price Quote

ENS Hydraulic Nut Splitter Triple edge replaceable cutting blade Blade positioning scale to eliminate bolt damage Cutting depth adjusted by rotating the cylinder Size Range from 3/4" to 3-1/2" bolt diameter Designed to fit BS1560/ANSIB16.5 flanges Special subsea versions available Versatile, reliable and trouble-free operations Operates off a standard 10,000 psi pump unit Order a cylinder and head to make complete nut splitter. Cylinders are interchangeable with heads within specific size ranges. Each are sold separately.

Hammer Mill

Get Price Quote

1 Piece(s) (MOQ)

We are offering hammer plant. For heavy wet and dry grinding, puree, paste, chutney. Heavy duty motor to take load on continuous basis.

Hydraulic Nut Splitter

Get Price Quote

We manufacture superior quality Hydraulic Nut Splitter in various specifications. The Hydraulic Nut Splitter offered by us is made from special alloy steel sourced from trusted vendors. The Hydraulic Nut Splitter offered by us is carried out at every stage of manufacturing to achieve the highest accuracy and long life during use. We are among the renowned manufacturers and suppliers of Hydraulic Nut Splitter in India. The highly reasonable prices at which we offer our Hydraulic Nut Splitters have contented the client�s to a greater degree. Features : Easy operationCompact designLightweightSingle acting spring returnOperates without making noiseReplaceable chiselComplete finishEquipped with a cylinder Uses : Quickly cuts and remove seized nutsUsed in petrochemicals, steel plant, marine, mine, construction & cement plants

Mini Colloid Mill Machine

65,000 Per Piece

Inline Colloid Mill

Get Price Quote

By way of introduction. We are pleased to introduce Parag Pharma Pump And Equipment is one of the leading manufacture of Inline colloid Mills developed for the first time in India, suitable for total dispersion of pharmaceutical formulation, creams and cosmetics,ointment,food products,etc. The process is carried out in single pass under a closed and pressurized system with improved color, reactivity and with no contamination. They come as tailor made for particle size reduction. This allows the industries to choose the colloid mill as per their specific requirements. The construction of the Mill is in stainless with built in jacket for heating or cooling, serrated rotor stator design with calibrated hand wheel adjustment with micrometer indicator for precisely varying the grinding gap between rotor and stator during the operation. In a short period of time we have achieved high level of technical excellence meeting the customers requirement resulting in an acceptable quality supported by series of trials conducted at our works. SALIENT FEATURES Inline Horizontal design Works under closed and pressurized system Process is carried out in single pass under hydraulic shear Discharge at elevated level Temperature rise is minimum and no aeration Quality uniform throughout the batch Can handle high viscosity media Improves color, reactivity with no contamination Jacketed mill housing for heating/ cooling Simple to use, easy to clean, less expensive to maintain Parag Pharma Pump And Equipment has develop for the first time in India, Horizontal Model inline-Colloid Mill for the Quick processing of all types of emulsions, dispersions of various media and micro grinding under wet condition. Colloid Mills have innumerable users. To list a few, manufactures of adhesives, cosmetics, coatings, ceramics, dyes and pigments, food products, insecticides, latexes, paints, toothpastes, pharmaceuticals etc. Parag Pharma Pump And Equipment backed by the two decades of technical excellence and experience in the process industries has the answer for getting difficult solid-liquid and liquid-liquid product mix inti.

Colloid Mill

Get Price Quote

SPECIAL FEATURES * All contact parts are made out of SS304 SS316 SS316 L quality material. * Coupling provided between motor shaft and rotor for the ease in maintenance. * 3 way valve system for draining and re-circulation of liquids or discharge spout for viscous products can be provided. * Contact parts can be easily dismantled for cleaning. * Flame proof construction provided if customer requires. * Jacketed model with jacket to the hopper.

Colloid Mill

Get Price Quote

Operation Product is fed to the operating area of rotor, having a speed of 3000 rpm by specially designed feed device. The product is processed by high shear, pressures & friction between the stator & rotor, & is also subjected to intensive vibration which exerts their force on it by means of pressing & releasing actions. due to the slightly deviating tapering of the milling surfaces of stator & rotor, the angular gap becomes narrower towards the discharge section. This processed product continuously leaves the mill through the drain pipe, if required, it can be recirculated. Salient Features All contact parts are made out of SS. 304 (SS.316 on demand at extra charges). No casting are used for avoiding contamination problems. Coupling provided between motor shaft & rotor shaft for ease in maintenance. Three oil seals between the Motor & the processing chamber to prevent liquid going in the motor winding, Resulting in the burning of the motor. Modified design of semi concave teeth in rotor & stator reduces the motor HP & gives better performance in size reduction without damaging the product. Extended bearing housing specially designed to facilitate fine adjustment of bearing clearances or back lash to avoid metal to metal contact of rotor & stator. This unique design provides smooth & consistence all round performance & ong life of rotor & stator. Leak proof neoprene sealing device. Three way cock system for draining & recirculation of liquids provided as standard. Extra discharge spout provided as standard for viscous products. DOL Starter with over load relay for protection against single phasing & low voltage. Contact parts can be easily dismantled for cleaning. Special design facilitates adjustments of the grinding gap by an exterior screw by means of handle even during operation. Flame proof motor &Flame proof rotary switch can be provided on request at extra cost. Output Depending upon material characteristics viscosity, density & micron size.

Granulation Colloidal Mill

Get Price Quote

It works on the rotor stator principle. The complete assembly is provided with serrations for better mixing. Better mixing can also be obtained by adjusting the gap between the rotor and the stator by the handle provided. The product is subjected to a high shear action in the rotor stator assembly due to which the particle reduction takes place. The material is then pushed out through the outlet for further process or for recirculation. The mill is optionally provided with a cooling water jacket and a mechanical seal for leak proof operation. Granulation Line:- Colloid Mills is suitable for homogenizing, mixing, emulsification, dispersion of liquids, ointment, creams, and other similar difficult to mix products. mill is optionally provided with a cooling water jacket and a mechanical seal for leak proof operation.

Rubber Grinder Mill

Get Price Quote

Rubber mixing mills (rubber processing machineries) are the Flagship of G.G. Engineering works. We offer mixing mills from 10”X24” to 26” X 84” with Anti friction spherical roller bearings having built in swivel action. We specialize in rubber processing machinery, rubber grinder mill and various other rubber machineries that are manufactured in our factory in Mumbai, India.

air attrition mill

Get Price Quote

The machine works along the same lines as the agitator mills. The vertical special agitator with self rotating hardened dot welded beaters is fitted with agitator shaft which are arranged in staggered positions one above the other and at a certain angle in relation to one another. The agitator runs in a con�tainer which can be cooled or heated, as required. Thus it is possible to process high-viscosity abrasive hard solid materials to grind one micron or less particles. Attrition milling is batch operation where materials to be ground are fed in as a suspension or as single components. A built-in product discharge valve with screen enables the separation of product and grinding media.

Colloid Mill

Get Price Quote

Colloid Mill

Get Price Quote

MEVISH Colloid Mill is suitable for Homogenising, Emulsifying, Dispersing, Mixing, Comminuting of liquids to highly viscous products. It is based on rotor- stator principle. It is available in plain as well as Water Jacketed model which is suitable for heat sensitive products. Flame proof electrical can be supplied on demand at extra cost. . Colloid Mill is based on Rotor and stator principle, as you decrease the gap between Rotor and Stator you can get fine product.Colloid Mill Machine is a machine used in the disintegration of solid particles or droplet size of a liquid present in suspension or emulsion. The Colloid Mill Machine consists an inlet (which is subjected to a tremendous shearing action that effects a time dispersion of uniform size) and an outlet. Colloid mill works on the rotor-stator principle.

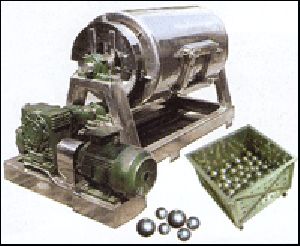

Ball Mill Motor Driven

Get Price Quote

Description :-For mixing & grinding, electrically operated having capacity of few gms to 1 KG & 2 KG. Fitted with geared motor with max speed of 80 rpm. The jar is made of SS and having steel balls of different sizes to be put in jar for mixing & grinding pesticides power. Jar is interchangeable and easily removable, light in weight and compact unit working on 220 V AC with 1 KG cap.— do — SS Drum 2 KG capacity— do — Aluminium Drum 1 Kg Capacity— do — Aluminium drum 2 KG capacity

Fibre Optical Splitter

Get Price Quote

With the assistance of our capacious warehouse and sophisticated inventory system, we are able to meet the bulk as well as urgent requirements of the clients. Moreover, our experts keep a stringent check on the safety of the products. The organization is indulged in offering secured payment procedure including both online and offline methods. To maintain more clarity of the transaction, we offer an invoice as well.

Motor Driven Disintegrator

Get Price Quote

Description :-Laboratory Size, hammer type with H. P. heavy duty motor (single phase) 220 volts, 50C/s A.C. consisting of four steel hammers fixed to a disc of 3″ in dia 1″ thick through which passes a shaft being revolved at 3000 RPM. The hammers are enclosed in a C.I. drum, the sides and upper surface of which are roughened in a C.I. drum, the sides and upper surface of which are roughned. The inner surface is undulating. The lower part of drum is made of chrome plated brass and is detachable so that SS sieves of different mesh size (a set of three sieves of coarse, medium & fine) supplied with the instrument can be easily placed. Hopper is made of die casted aluminium, built on angle iron frame of size 24″ x 14″ x 20″ high.

Colloid Mill

Get Price Quote

• Unique for Grinding , Homogenizing , Emulsifying , Dispersing , Mixing and Extracting. • Versatile Machine for Homogenizing and Milling Upto 5 to 10 Micron Particle. • Three way Cock System for Draining and Recirculation of the Liquids Provided as Standard. Extra Discharge Sprout Provided as a Standard for Viscous Products. • Modified Design of Semi Concave Teeth in Rotor and Stator Reduces Motor H.P. and Gives Better Perfomance in Size Reduction without Damaging the Product. • Contact Parts Can Easily Dismantled for Cleaning.

Ball Mill

Get Price Quote

Excellent for dry & wet fine grinding , mixing, reacting of colour paints, emulsifiers, enamels, refractoriies etc. Micro Ball Mills are provided with twin mouths for charging & discharging. Additional Gear & pinion are provided which results in power saving & smooth running.

Ball Mill Grinder Machine

Get Price Quote

We are working with a pool of professionals who are diligent at their work and make sure that the offered lot is packed in high quality material and timely dispatched. Our products are the most sought after in the market, as they are specifically made as per global and domestic quality managements.

TV Satellite Splitter

300 Per Piece

10 Piece (MOQ)

Hammer Mill/Pulversier

41,000 Per Piece

LL Pulversier comes with powerful crusher and best quality grinding at much higher speed. Usage For heavy wet and dry grinding, puree, paste and chutney. Model : PUL01-3 Hp Capacity 20 to 30 Kg http:llequip.com?page_id=34