horizontal sand mill

Get Price Quote

1 Piece (MOQ)

Grinding Mill

Get Price Quote

Best Deals from Grinding Mill

horizontal colloid mill

175,000 - 275,000 Per Piece

1 Piece (MOQ)

With us, buyers are free to place orders and can expect timely deliveries of the same. For the safe storage of the entire lot, we have installed our own facility that is laced with all the modern amenities for complete quality satisfaction. Model : 1 HP / 3HP / 5HP

FBT Fiber Optic Splitter

Get Price Quote

1 Piece (MOQ)

Rock Breaking, Hydraulic Rock Splitter

Get Price Quote

We are offering Hydraulic Rock Splitter.

Ultrafine Mill

Get Price Quote

1 Piece (MOQ)

Vertical Colloid Mill

Get Price Quote

Features : No castings are used for avoiding contamination problems. Coupling provided between motor shaft and rotor shaft for ease in maintenance —Vertical Model. oil seals between the motor and the processing chamber to prevent liquid going in the motor winding, resulting in the burning of the motor. Modified design of semi concave teeth in rotor and stator reduced motor HP and gives better performance in size reduction without damaging the product. Extended bearing housing specially designed to facilitate fine adjustments of bearing clearances or backlash to avoid metal to metal contact of rotor and stator. This unique design provides smooth and consistence all round performance and long life of rotor and stator. Three-way cock for draining and re-circulation of liquids provided as standard. Contact parts can be easily dismantled for cleaning. Special design facilitates adjustment of grinding gap by an exterior screw by means of handle even during operation. Flameproof motor and flameproof rotary switch can be provided on request at extra cost.

3 HP Stainless Steel Colloid Mill Machine

95,000 Per Per Machine

1 Unit (MOQ)

Ball Mill

Get Price Quote

We are offering Ball Mill. we manufacture and supply superior quality ball mills that are made from premium quality materials that offer sturdy structure and durability to them. the world class ball mills offered by us are designed by expert team of designer keeping the specific needs of our clients in mind. the wide demand of our ball mills in the market proves our claim of being the prime ball mill manufacturer and supplier from vasai, maharashtra. features made from premium quality materials designed by expert teamunique construction durable anti corrosiveanti abrasive widely used in chemical industriespaint industries food industries construction industries pharma industries steel industries beverages industries etc.

Ultrafine Mill Machine

Get Price Quote

1 Piece (MOQ)

Colloid Mill

90,000 Per Piece

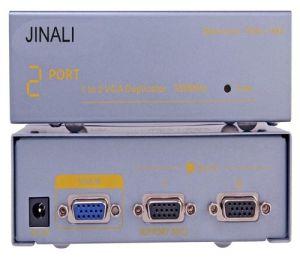

JV08/2-250 VGA SPLITTER 1X2

900 Per Pair

Jv082-250 jv082-250 vga splitter 1x2 support up to 30 mtrs 1x2 रु1,800 2 900 720 black box vga video splitters allow you to send clear eye-catching images to 2 monitors from your pc. these video splitters are great for presentations, trade show or point of sale displays, or for displaying multimedia video to large audiences at sales or training meetings. Support up to 30 mtrs description 4-port vga splitter for industrial and automotive use, supports over 1600x1280, duplicates vga signal to 4 outputs for multi-monitors, 11~24volt dc input features • supports over 1600x1280 • duplicates vga signal to 4 outputs for multi-monitors • industrial automotive grade • support 30 mtrs • metal body,powder coated • 250 mhz support 30 mtr length

Laboratory Attritors

Get Price Quote

Known for several features such as fast and efficient grinding, easy operation, flexibility etc., our Laboratory Attritors are widely acclaimed by clients. Laboratory Attritors are used for obtaining homogenous and fine dispersions under controlled conditions. These Laboratory Attritors have a compact design, and are used for agriculture flowables, chemicals, ceramics, metal oxides etc. SF Attritor is used for producing fine & homogenous dispersons quickly & repeatedly under controlled conditions. Used for the manufacture of ceramics , inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals & pharmaceuticals. The Attritor is often referred to as a agitated ball mill. The material to be ground is charged into a vertical tank filled with grinding media. Both the material and grinding media are then agitated by a shaft with arms causing the media to exert shearing & impact forces on the material. This action produces an extremely fine material measured in microns. No pre mixing is required. All attritors are provided with cooling jackets. Recirculating facility is available as optional. Attrition Mills, Also Called Stirred Ball Mills, Are A Very Fast, Powerful And Efficient Method For All Operations Of Grinding, Blending And Milling, Either Wet Or Dry. The Advantage Of An Attrition Mill Is That It Ensures That All The Grinding Media Are In Action All The Time. This Results In Much Faster Action. For Example, Wet Milling A Casting Slip Can Be Completed In One Tenth Of The Milling Time Required In A Conventional Ball Mill. Advantages of Using a Batch Attritor Ten times faster than ball mills Simple to operate Energy efficient No premixing required Minimum maintenance required Rugged construction Compact design No special foundation necessary Advantages of SF Lab Attritor Fast And Efficient Grinding, Scale-Up Capability, Numerous Options, No Premixing, Flexibility, Easy Operation, Repeatability, Low Maintenance SF Customer Knows From Experience That The Attritor Is One Of The Most Versatile Pieces Of Equipment In There Lab. It Can Be Equipped Or Retrofitted Easily And Inexpensively With A Wide Variety Of Components And Accessories. With The Attritor, Users Can Choose Wet Or Dry Grinding, Introduce Inert Atmospheres, Operate At Controlled Temperatures, Vary Grinding Speed, Overcome Product Contamination, Change Media Size And Type, And Get Precise Energy Consumption Information, All On The Same Machine. Results Are Repeatable From One Test Grind To Another For Maximum Credibility. Finally, The Attritor Is Ideal For Formulating, Quality Control, And Scale-Up Studies. Uses Paints, toners, inks Ceramics Agricultural flowables Food products Chocolate, confectionery Paper coatings, calcium carbonate, clay Chemicals Ferrites Metal oxides Minerals, ores, coal Sulphur dispersions Operating Principal Machine Operates According To The Principle Of An Agitator Bead Mill. The Vertically Arranged Special Agitator Is Equipped With Agitator Pegs.Ideal Flow Conditions Are Reached Through The Combination Of Optimally Arranged Agitator Pegs And The Hemispherical Grinding Chamber FloorCirculation Grinding Guarantees An Exact Reproducibility And High Product Homogeneity. Working The Attritor Is Often Referred To Generically As A �Stirred Ball Mill.� The Operation Of An Attritor Is Simple And Effective. The Material To Be Ground Is Placed In A Stationary Tank With The Grinding Media. Carbon Steel, Stainless Steel, Chrome Steel, Tungsten Carbide And Ceramic Balls Are Commonly Used Media. The Material And Media Are Then Agitated By A Shaft With Arms, Rotating At High Speed. This Causes The Media To Exert Both Shearing And Impact Forces On The Material. The Final Result Of This Remarkably Efficient Process Is An Extremely Fine Material, Measured In Microns Or Fractions Of Microns, Distributed On A Very Narrow Curve. The Laboratory Attritor Works Up To Ten Times Faster Than The Conventional Ball, Pebble Or Jar Mill. Its Compact, Vertical Profile Requires Minimal Space. No Premixing Is Necessary. Adding Ingredients (Or Taking Samples) Can Be Done At Any Time During The Grinding. Construction The Vessel Is Made From Thick S.S.304. Material To Withstand Heavy Loads And Is Provided With A Top Cover In Two Halves Which Can Be Locked On To The Main Vessel By Means Of Eye Bolts. A Jacket In M.S. Construction For Heating And Cooling Is Provided Complete With Inlet Outlet And Drain Fittings. Cooled Chamber And Product Pipeline. A Specially Designed Ball Valve With Strainer Is Provided At The Bottom Of The Vessel For Quick Discharge Of The Material. The Complete Vessel Is Mounted On Steel Shaft Perfectly Balanced And Housed On The Frame Structure. The Entire Vessel Can Be Tilted By Means Of A Mechanical Device To Facilitate Cleaning Operations. Residue-Free Discharge And Easy Cleaning Due To Dish Bottom Chamber. The Main Shaft Is Connected To The Output End Of The Gear Box Assembly By Means Of C.I./M.S. Rigid Flange Type Coupling. The Shaft Is Carefully Machined And Fitted With Specially Designed Adjustable Attrition Arms Which Rotate At 120 RPM. The Unit Is Painted With 2 Coats Of Metal Primer And 2 Coats Of Synthetic Enamel Paint. Electricals : All Electrical Are 3 Phases, 50 Cycles, and 400 V. Panel : The Machine Is Complete With An Electrical Panel Consisting Of Ammeter, Voltmeter And �ON/OFF� Switches. Drive : The Drive Unit Is Enclosed In Steel Cabinets Supported And Stiffened By Structural.

Power Splitter

Get Price Quote

Power Splitter, Air Compressor, Mining Services, Hydurilic splitter

GUN SPLITTER

Get Price Quote

Gun Splitter Quick-flush feature saves time and materialLets you use two spray guns with one XP SprayerThe Graco Gun Splitter lets you use two spray guns with one XP Plural-Component Sprayer. In addition, you can independently clean and flush one gun, while the other gun remains in use. If you’re using a higher production XP machine such as the XP50 or XP70, the Gun Splitter helps you become even more productive.Features:Independently sprays or flushes two guns for faster-setting materialsSaves time, improves uptimeLess solvent wasteDesigned with minimal dead space, greatly reducing material build-up inside the splitter

PSI LAB Air Jet Mill

Get Price Quote

r & d model or qualifying model emco has designed this new and compact lab model for r & d purpose and also it acts as a qualifying model for the higher size production models. the latest designed computational fluid dynamics (cfd) is a branch of fluid mechanics that uses numerical analysis and data structures to solve and analyze problems that involve air flows. computers are used to perform the calculations required to simulate the interaction of carrying medium with surfaces defined by boundary conditions. this subsequently improved geometry of the milling chamber and ring integrated nozzles have led to a very narrow psd (particle size distribution). documentation to support fda validation design qualification (dq) operation qualification (oq) factory acceptance test (fat) installation qualification (iq) performance qualification (pq) features of jet mill - emco psi lab narrow particle size distribution (psd) simple and rapid assembly or disassembly limited number of components low energy consumption sterile manufacturing no heat generation no cross contamination variety of available liners to resist abrasion benefits for the cosmetics industries ultra-fine loose and compact powders improved metallic pigments effect perfect skin adherence increased binding effect ultraviolet radiation reflecting properties

Colloid Mill

Get Price Quote

Colloid Mill is an ideal & perfect homogenizer cum emulsifier Feed Hopper, recirculating pipe & mouth hopper are supplied as standard with colloid mill. Fine particles size at high speed Lower Maintenance Models available in AISI SS 316 / AISI SS 304 MOC Available in Jacketed / Non-Jacketed type. Drive mechanism is an electric motor with couple shaft Special 3 way valve is provided for recirculation & discharge of the product. Finish products available as low as 5 micron. It is suitable for small, medium as well as large batches of production cGMP Construction With High Pharmaceutical Finish With Documentation .

Horizontal Flour Grinding Mills

Get Price Quote

- Suitable for Grinding sugar, wheat, rice, maize, corn, coffee, cocoa, food grains, spices, etc. - Supplied with Synthetic Black Emery Stones or Natural Red Emery Stones. - Stones supplied in Black Bond or White Bond as per customer's requirement - Supplied with Flat Pulley - Prime Mover (Electric Motor or Diesel Engine) supplied on request at extra cost

Hdmi Splitter

Get Price Quote

We are the main supplier of this product.

Colloid Mill

Get Price Quote

We are among the most trusted firms, engaged in manufacturing, supplying and exporting Colloid Mill Machine. Designed to perfection, our machines are manufactured using quality material and components that are sourced from the reliable vendors of the market. These machines are provided to customers in various models and sizes at market leading prices. Also, we provide tailor-made solution for Colloid Mill Machine as per clients needs.

Yamamoto Ultra Large Hydraulic Rock Splitter

10,000,000 - 13,000,000 Per Piece

Yamamoto hydraulic rock splitters can be mounted on any brand of excavator from 12~23 ton class. It is used for splitting hard rock vertically & horizontally.

horizontal sand mill

Get Price Quote

Root Laboratory 0.5L horizontal sand mill is specially designed for dispersing and grinding of sub-micron, micron, sub-nano and nano grade material. The high efficient cooling system and fine-gap centrifugal separating system could avoid the block of material in separator and ensure a smooth product discharging. It is specially used in the lab formulation research and small batch production. The lab mill grinding result could be scaled up to the industrial production.

MTM Trapezium Grinder

Get Price Quote

MTM Medium Speed Trapezium grinder is a kind of leading-world-level industrial milling machinery. It is designed by our own engineers and technical workers, basing on industrial mill research of many years and adopting world-leading-powder processing technology. Now a number of customers are fond of it for its incomparable features. Features Technical improvement based on environmental protection concept.. High efficient and energy saving centrifugal draft fan. High density and precision impeller device. Quick adjustment and maintenance

Hydraulic Nut Splitter

Get Price Quote

We manufacture superior quality Hydraulic Nut Splitter in various specifications. The Hydraulic Nut Splitter offered by us is made from special alloy steel sourced from trusted vendors. The Hydraulic Nut Splitter offered by us is carried out at every stage of manufacturing to achieve the highest accuracy and long life during use. We are among the renowned manufacturers and suppliers of Hydraulic Nut Splitter in India. The highly reasonable prices at which we offer our Hydraulic Nut Splitters have contented the client�s to a greater degree. Features : Easy operationCompact designLightweightSingle acting spring returnOperates without making noiseReplaceable chiselComplete finishEquipped with a cylinder Uses : Quickly cuts and remove seized nutsUsed in petrochemicals, steel plant, marine, mine, construction & cement plants

Hammer Mill

Get Price Quote

Hammer Mills are used to pulverize copra, palm kernel & other oil seeds. The Hammers (Beaters) are rectangular for efficient grinding and are made from hardened alloy steel. Salient Features : Easy opening arrangement. Easy removal of the mesh which leads to less down time due to chocking. Hardened tempered specially designed rectangular beaters. Grater plates are provided to ensure efficient pulvarising. Alloy steel well balanced rotor shaft supported on self aligning double raw spherical roller bearing ensure a very smooth, vibration free rotation of the rotor. Hammer mill and motor mounted on a single base frame with shock absorption rubber padding. MODEL CAPACITYHR H.P.REQUIRED HM-A1 500 KGS 7.5 HP HM-1 1000 KGS 20 HP HM-2 2000 KGS 40 HP HM-3 3000 KGS 50 HP HM-5 5000 KGS 75 HP HM-8 8000 KGS 100 HP

Bead Mill

95,000 - 180,000 Per Set

1 Set(s) (MOQ)

Hdmi Splitter

4,500 - 4,600 Per Piece

Ball Mill

Get Price Quote

Hammer Mill

Get Price Quote

1 Piece (MOQ)

pug mixer

Get Price Quote