TUBE ICE PLANT / TUBE ICE MACHINE

Our Tube Ice Machines are designed to satisfy the varying needs of different industries and customers. Capacity varies from 1300 kg. to 40,000 kg. of tube ice per day. These machines are operational on ammonia (NH3) & Freon (R-22) as refrigerant. We supply a perfect tube ice machine no matter what’s your need, if any of our many models does not suite your need. We will gladly work with you to custom design a model that fulfill your requirement. The unique design of our Tube Ice Machine freezes ice automatically in the vertical stainless steel tubes by the refrigerant circulating around tubes in freezer shell, the swirl of water falls from top of each tube, the hole is formed during the formation of ice because the falling film of water, freezing takes place inside the vertical tubes, as the water freezes the impurities are washed back to the sump tank to be released as and when required, when the ice in the tubes is frozen to the desired thickness. Hot gas is released automatically in to the freezer shell releasing tubes of ice on to a cutter, the cutter cuts the pieces of desired preset length. The cylindrical ice is available in three standard diameter 1.3/8” (34mm.), 1.1/8” (28mm.) & 7/8” (22mm.) standard length is approximately 1” or can be designed to customer requirement.

...more

tube ice plant machine

Our tube ice machines are designed to satisfy the varying needs of different industries and customers. Capacity varies from 1300 kg. To 40,000 kg. Of tube ice per day. These machines are operational on ammonia (nh3) & freon (r-22) as refrigerant. We supply a perfect tube ice machine no matter what’s your need, if any of our many models does not suite your need. We will gladly work with you to custom design a model that fulfill your requirement.

...more

Tube Ice Machine

Highly efficient consumes less power. » Lesser space required for production. » Ice Produced in batches of 20-25 minutes. » Minimum Maintenance and does not require any replacement parts for a long period. » Investment lower than Block Ice Plant. » Easy delivery through screw conveyers. » Can be sold in any packed quantity for any use.

...more

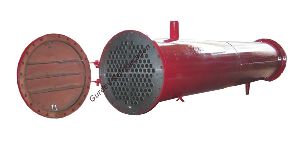

shell condenser

We make horizontal shell and tube ammonia condenser, which are available in different capacity ranging from 5tr to 400 tr.a shell and tube condenser (heat exchanger) is the most common type of heat exchanger used in refrigeration industry.

...more

Shell and Tube Condenser

We make Horizontal Shell and tube ammonia condenser, which are available in different capacity ranging from 5TR to 400 TR.A shell and tube condenser (heat exchanger) is the most common type of heat exchanger used in refrigeration industry.Shell and Tube Condensers are having two divisions one is shell and other is Tubes. Here water runs through the tubes, and ammonia vapor flows over the tubes (through the shell) to transfer heat between the two fluids. For this purpose seamless/ERW or Rolled shell are used for shell. And Seamless/ERW tubes are used for Tubes. Different Pass Arrangements are made by providing baffles in the water heads, Like Two, four, six and eight pass designs are common because the fluid can enter and exit on the same side. This makes construction much simpler and Helps to limit the tube Length.The ammonia vapors enter the shell and get condensed by rejecting the heat to the circulating water in the tubes there are Baffles directing flow through the shell side so the vapor does not take a short cut through the shell side leaving ineffective capacity.These shell and tube condensers are tested at a hydrostatic pressure of 27 kg/sq. cm gauge (380 psig). We also make shell and tube condensers with SS tubes and SS water heads where the water is saline or very hard so the tubes can be cleaned easily with chemicals.

...more

Plate Freezer

Ice Plant Machinery

Tube Ice Machine freezes ice automatically in the vertical stainless steel tubes by the refrigerant circulating around tubes in freezer shell, the swirl of water falls from top of each tube, the hole is formed during the formation of ice because the falling film of water, freezing takes place inside the vertical tubes, as the water freezes the impurities are washed back to the sump tank to be released as and when required, when the ice in the tubes is frozen to the desired thickness.

...more

Ice Cans

We are one of the leading manufacturer supplier and exporter of ice cans in India since 1982. The Ice cans are made from 16 gauge Galvanized Iron sheet (1.53mm – 1.55mm. thick). The M.S. Ring is riveted at the top of the can in which holes for lifting pins are made. The ring reinforces the top and prevent it from damaging and to further reinforce the cans from sides. These cans are made with single or double groove at the sides depending upon the size to make the cans sturdy and long lasting. These Ice cans are available in standard sizes of 50 lbs, 100 lbs, 200 lbs, 300 lbs, 400 lbs & 500 lbs, but we can also offer our clients, an array of ice cans of different size and standard that is designed in compliance with international quality standard. The smooth construction of these ice cans with slight taper towards the bottom enables the ice block thawing very easily. Each ice cans is strictly tested for leaks so it ensures a leak proof service.

...more

Evaporative Condenser

Condenser Shell

Condenser shell are available in different capacity ranging from 5TR to 400 TR.A shell and tube condenser (heat exchanger) is the most common type of heat exchanger used in refrigeration industry. Shell and Tube Condensers are having two divisions one is shell and other is Tubes. Here water runs through the tubes, and ammonia vapor flows over the tubes (through the shell) to transfer heat between the two fluids. For this purpose seamlessERW or Rolled shell are used for shell. And SeamlessERW tubes are used for Tubes.

...more

cold storage plant

cold storage door

BrINE Agitators

We manufacturer two different models of Brine Agitator. MONO BLOCK / COUPLED BRINE AGITATOR Made up of heavy duty M.S. Pipe in which a 1½” (38 mm.) shaft is fitted with gunmetal bush at both ends or taper rolling / ball bearing as required by the customer. These agitators are fitted with 14” Dia. C.I. Impeller/ Fan and the capacity of the agitator can be varied by changing the degree of Impeller/ Fan blades. V BELT DRIVEN BRINE AGITATOR Made up of heavy duty M.S. Pipe in which a 2" (50 mm.) Shaft is fitted. The shafts has gunmetal bush at the fan end and taper roller bearing at the pulley end and are fitted with various sizes of C.I. fan / impeller. i.e. 8”, 12”, 16”, 18” & 20” according to capacity of the ice plant. These agitators come in different models suitable for various depths of tank or as per customer requirement.

...more

Air Cooling Units

air cooling shells

Condensers

coupled agitators

Ice Plant

oil receivers

Oil Separators

Refrigeration Equipment

tube chillers

Air Cooling Unit

AXIAL FAN

Be first to Rate

Rate ThisOpening Hours