Cooling Tower Grid Fills

Get Price Quote

10 Piece(s) (MOQ)

Optic Grid Fills Is A Direct Replacement Splash Fill For Use In Counter Flow Cooling Tower Where Dirty Water Is A Concern .Optic Grid Splash Fills Is Maximizing Number Of Water Drop Lets & Highest Surface Of Water Are Passing Through Air .This Fills Are Made Of Polypropylene,(Pp) It Is Resistant To Attack From Acids, Alkalis, Muddy Water , Ash, Etc.

Cooling Tower

Get Price Quote

Best Deals from Heat Exchangers

blanking panels

350 Per Piece

5 Piece (MOQ)

Condenser Shell

Get Price Quote

Condenser shell are available in different capacity ranging from 5TR to 400 TR.A shell and tube condenser (heat exchanger) is the most common type of heat exchanger used in refrigeration industry. Shell and Tube Condensers are having two divisions one is shell and other is Tubes. Here water runs through the tubes, and ammonia vapor flows over the tubes (through the shell) to transfer heat between the two fluids. For this purpose seamlessERW or Rolled shell are used for shell. And SeamlessERW tubes are used for Tubes.

Condenser Tubes

Get Price Quote

Condenser tubes in annealed and pickled, bright annealed, mill finish and polished conditions. One of our client from Saudi Arabia says that Trident Steel always has the quality inventory to cover our needs and the personnel that ensures it gets to us on-time, every time.

Vertical Accumulators

250,000 Per Piece

rcc cooling towers

Get Price Quote

Manufactures & exports concrete (RCC) counterflow cooling towers using vide varieties of film and splash fills selected based upon the circulating water quality, either for fresh water or sea water application. Generally, reinforced cement concrete cooling towers are constructed as per the requirement of the customers. These towers are either offered on a turnkey basis by Canara or Civil construction can be in the customer's scope. However, detailed Engineering for RCC construction is offered by Canara. Designing and construction is done in accordance with Indian Standards (IS) or American Concrete Institute (ACI) standards.

Double Tubesheet Heat Exchanger

Get Price Quote

We are offering double tubesheet heat exchanger. Total qty.: 16 nos. (exotic materials) shell & dish: sa 240 tp. 304l sa 516 gr. 70 tube: sb 622 n10276, sb 163 n06600, sb 163 n08800, sb 165 n04400, sa 789 s32750 & sa 312 tp. 304 flange: sa 266 gr. 2, sa 336 f 304l & sa 350 lf 2 tube sheet: (sa266gr.2+sb575 10276), (sa266gr.2+sb 168 n0660), (sa266gr.2+sb409 n08800), (sa266gr.2+sb127 n04400), (sa 350 lf2+sa240 s032750) & (sa266gr.2+sa240 s032750). Third party inspection: ibic engineering, lloyd's register asia & ibr

tube type condenser

Get Price Quote

We can supply both Shell and Tube type Condenser. These shell condensers, tube condensers are designed specially, as per the heat load, for the vapour to travel a longer distance for effective condensation.

Mould Cooling Nipples

20 Per Piece

Air Cooled Condensers

250,000 Per Piece

Silent X-Stream Panel Coolers

Get Price Quote

The Silent X-Stream™ Frigid-X™ Panel Cooler series for electronic control panels provide a low cost method of both purging and cooling electrical and electronic control panels by using a stainless steel vortex tube to create cold air from ordinary compressed air. Utilizing a hot and cold end muffling kit the unit is made extra quiet to under 64 dBA depending on capacity. The hot end muffler also acts a "heat guard" - you can actually wrap your hand around it without feeling much heat. The hot air is exhausted safely underneath the hot end muffler. The Silent X-Stream™ Frigid-X™ Panel Cooler series are compact and can be installed in minutes through a standard electrical knockout. There are virtually no moving parts. Features Low in cost Compact No CFC's Fast installation Stabilize enclosure temperature and humidity Virtually maintenance free (No Moving Parts) Mounts in a standard electrical knockout Stops heat damage and nuisance tripping Eliminates fans and filters Prevents dirt contamination by keeping enclosure at positive pressure Units applicable to all environments including high temperature to 200°F

gas cooler

Get Price Quote

Fin Tube Heat Exchangers

Get Price Quote

We are offering fin tube heat exchangers.aluminum fin, copper tube heat exchanger pipe size 3/8, 1/2, 5/8 fin material aluminum, copper, ss, haider or distributor as required.

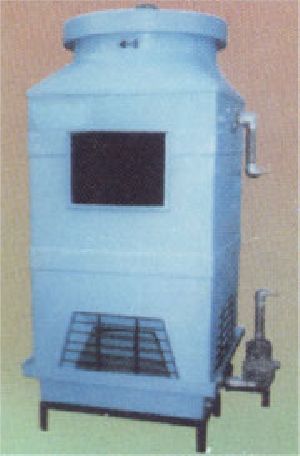

Frp Cooling Tower

Get Price Quote

We are involved in offering a wide range of F.R.P. Cooling Tower to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.We introduce ourselves as an eminent trader and supplier of an extensive array of F.R.P. Cooling Tower. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.Features: Sturdy design Highly durable Application specific design

Air Aftercoolers

Get Price Quote

The unit is a shell and tube heat exchange with M.S. shell and Copper tubes. In case of Horizontal after cooler the water passes through shell over the tubes carring hot compressed air. There is a moisture separator provided at the out let of the cooler which removes the oil and water droplets formed due to cooling.

Heat Transfer

Get Price Quote

We are offering heat transfer. Duct serves the purpose of undisturbed surrounding complete panelized instrument for electric input digital voltmeter, ammeter & temperature indicator to determine average heat transfer coefficient calculate & plot variation of local heat transfer coefficient along the length of the tube.

T imber

Get Price Quote

Canara manufactures timber cross flow cooling towers with vide varieties of splash fills. Poor water quality problems are no problem with cross flow timber cooling towers. The cooling towers are heavy duty designed for Industrial applications, and specially suitable for dirty circulating water , as the splash bars do not clog easily. The timber is chemically pressure treated after fabrication , using CCA chemicals by the full cell process to a minimum chemical retention of 12 kg/m3 , as per IS – 401 Code , to protect the wood from decay & attack by termites and other micro organisms, to get a longer life. The Treated lumber is the most economical materials used in cooling towers. The chemically treated timber can withstand high levels of chlorides , sulfates and hydrogen sulfide.

Cooling Tower

55,000 Per Piece

Aluminium Heat Dissipators

Get Price Quote

coaxial heat exchanger

Get Price Quote

High Performance Coaxial Condensers are distinguished by a special design of the flow path. The counter flow principle for improved heat transfer is applied.

Brass Tube

Get Price Quote

Double Door Combination Cooler

Get Price Quote

Reboiler heat exchanger

Get Price Quote

Shell and tube heat exchangerShell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned, etc. Shell and Tube heat exchangers are typically used for high pressure applications (with pressures greater than 30 bar and temperatures greater than 260°C).This is because the shell and tube heat exchangers are robust due to their shape.There are several thermal design features that are to be taken into account when designing the tubes in the shell and tube heat exchangers.

Heat Exchanger

Get Price Quote

The heat required for evaporation is supplied by low pressure steam. The advantage is the utilization of generally available utility steam thus saving in other power cost. In the shell and tube heat exchanger type of our design, the LPG liquid is passing though the SS tubes and the steam is circulated around the tubes. A cross flow is maintained to ensure high heat transfer. Higher differential temperature results into higher co-efficient of overall heat transfer, thus making the unit compact compared to hot water circulation vapouriser unit. Steam enters the heat exchanger at top and return steam with condenset returns from bottom. Liquid LPG enters at bottom and vapour comes out from top. The steam is maintained at 2.5 bar per sq. cm pressure. If available, steam is at high pressure it needs to be reduced to 2.5 bar using a pressure regulator. The steam flow required is controlled by temperature sensor. If the load on LPG vapouriser reduces, the flow of steam also reduces suitably. This interlocks ensure saving of steam. The sensor senses the temperature of outgoing vapour. If vapouriser load decreases vapour temperature increases, and thereby reduces steam supply. Other interlocks includes: 1. LPG liquid supply controls based on pressure of the vapour after primary regulator. If consumption reduces this pressure increases cutting off the solenoid valve in the liquid supply line. As the pressure drops to set limit, the solenoid valve opens again. 2. A thermostatic control ensures that if the temperature in the shell is less than the set limit, LPG liquid will not be supplied to the unit. Indicating lamps are provided on control panel show the status. Safety relief valve is provided on the vapour outlet line ensures that the pressure in the heat exchanger does not rise beyond safe limit.

PVC Drift Eliminators

Get Price Quote

We are offering PVC Drift Eliminators manufactured from rigid PVC and are designed to remove entrained particles from air steam efficiently, with minimum pressure drop, thereby reducing the fan power requirement when the air passes through the drift Eliminator. Water droplets are separated from the air drift at the three direction change points on the drift eliminator. For crossflow tower applications, the almost vertical water conduits provided by the SPC 100 drift eliminator remove the water droplets out of the drift eliminator area and return them back into the tower and does not allow any re-entry. The special locking pin arrangement for SPC-100 facilitates quick and simple assembly at site. When used in counter-flow cooling towers, the measurable residual liquid load behind a droplet separator characterizes its efficiency. The performance data of our droplet separators have been determined under laboratory conditions. At a face velocity (CA) of 3.5 ms and a specific water flow (rw) -22tm2 h, the residual liquid load of the air is 15mgm3. If this residual load is related to the circulating cooling water volume this equates to a value smaller than 0.001%. Fundamental conditions required to achieve these high efficiencies in practice are, a workman like installation, the droplet separator sections must be installed without any gaps between themselves or the tower walls to ensure by passing does not take place. The face value shall not exceed the maximum permissible value at any position across the total area of the separator. Any performance testing of the separators must be carried out immediately above the separators and by using a test method consistent with that employed in our laboratory or otherwise agreed with ourselves. We can advise on the likely operating efficiencies of specific towers provided that their operating data are made available to us. Application Areas : Primary setting in wastewater treatment plants (suspended and flocculated solids) Secondary (biological solids) setting in wastewater treatment plants Solid-liquid separation in potable and industrial process water treatment plants, Anaerobic digesters (restrict loss of solids) Ash handling units in thermal power plants Process industry (material recovery from wash storm water) Oil-water separation

Static Mixer Heat Exchanger

Get Price Quote

Heat Transfer Lab Equipments

Get Price Quote

Heat Transfer Lab Equipments, engine lab equipments

Spiral Fin Tube

Get Price Quote

Spiral Fin Tube, Fin Tube, Sealing Machine

High Pressure Heat Exchanger

Get Price Quote

L&T Heavy Engineering has state-of-the-art manufacturing facilities which are capable of meeting the challenges of technology, quality conformance & delivery, while ensuring cost competitiveness. Nos. Supplied: Over 100, Process: HaldorTopsøe, KBR, Linde, ThyssenKruppUhde, Synthesis loop heat exchangers with thick tubesheet (thicknesses varying from 200 to 350 mm), fabricated from Cr-Mo Steel.