Polypropylene Cooling Tower Nozzles

Get Price Quote

10 Piece(s) (MOQ)

We Sgct Manufacturing Various Types Of Nozzle As Per Requirement & Base Upon Design, Pressure Required

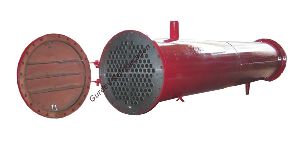

Shell and Tube Condenser

Get Price Quote

We make Horizontal Shell and tube ammonia condenser, which are available in different capacity ranging from 5TR to 400 TR.A shell and tube condenser (heat exchanger) is the most common type of heat exchanger used in refrigeration industry.Shell and Tube Condensers are having two divisions one is shell and other is Tubes. Here water runs through the tubes, and ammonia vapor flows over the tubes (through the shell) to transfer heat between the two fluids. For this purpose seamless/ERW or Rolled shell are used for shell. And Seamless/ERW tubes are used for Tubes. Different Pass Arrangements are made by providing baffles in the water heads, Like Two, four, six and eight pass designs are common because the fluid can enter and exit on the same side. This makes construction much simpler and Helps to limit the tube Length.The ammonia vapors enter the shell and get condensed by rejecting the heat to the circulating water in the tubes there are Baffles directing flow through the shell side so the vapor does not take a short cut through the shell side leaving ineffective capacity.These shell and tube condensers are tested at a hydrostatic pressure of 27 kg/sq. cm gauge (380 psig). We also make shell and tube condensers with SS tubes and SS water heads where the water is saline or very hard so the tubes can be cleaned easily with chemicals.

Best Deals from Heat Exchangers

Condenser Tubes

Get Price Quote

Condenser tubes in annealed and pickled, bright annealed, mill finish and polished conditions. One of our client from Saudi Arabia says that Trident Steel always has the quality inventory to cover our needs and the personnel that ensures it gets to us on-time, every time.

Static Mixer Heat Exchanger

Get Price Quote

blanking panels

350 Per Piece

5 Piece (MOQ)

tube type condenser

Get Price Quote

We can supply both Shell and Tube type Condenser. These shell condensers, tube condensers are designed specially, as per the heat load, for the vapour to travel a longer distance for effective condensation.

fiberglass cooling towers

Get Price Quote

There are 5 models under single cell specific and 18 models under multi-cell configurations. These Cooling Towers are primarily supplied in Fibreglass Reinforced Polyester (FRP).

Cooling Tower Spare Parts

Get Price Quote

Cooltech Cooling Equipments uses high quality cooling tower spares like Rotary Sprinklers, PVC Fills, Fan Assembly and FRP Casings for Cooling towers. Cooltech is also a supplier of Cooling tower spares contact 9322274824 to order any of these spares which are available in different sizes for different capacity cooling towers.

ERW Boiler and Heat Exchanger Tubes

Get Price Quote

Size Range: ½” od to 4” OD, W.th. 1.6mm to 5mm Grade: BS: 3059 Gr.320ASTM A 214Also available AIR HEATER TUBES as per BS: 6323 Part V

Cooling Nipples

20 Per Piece

Pultruded FRP Cooling Towers

Get Price Quote

Along with manufacturing a wide variety of new cooling towers due to our flexible, project oriented Engineering and designs, Canara has diversified, expertise in conversion of old timber cooling towers to pulturded FRP cooling towers. Many cooling tower users prefer to repair existing old timber cooling towers, which either have out lived their life or damaged prematurely due to bad quality of materials or other reasons. In reality if the overall condition of the existing cooling tower is bad and requires a major structural repairs, then it is technically and economically advised to convert the old timber cooling tower to pulturded FRP cooling tower. During repairing of old timber cooling towers, only part of the bad quality items are replaced, so un replaced items need to be replaced after some time. Practically repairing of old timber cooling towers takes place every 1- 2 years, which proves very costly affair. Moreover partially repaired old timber cooling tower may fail, collapse partially or fully, which will be dangers in all aspects.

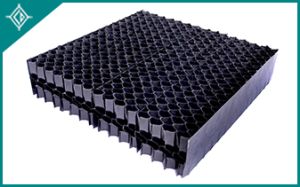

Double Wall Drift Eliminators

Get Price Quote

Drift Eliminator

Get Price Quote

Drift eliminators are used to capture water droplets in the air stream that otherwise would be lost to the atmosphere. Entrapping these droplets is important for not only conserving water as a resource but also to prevent cooling tower water from contaminating the area peripheral to the cooling tower. The cooling tower industry uses drift rate to compare drift eliminator performance, a relationship that correlates droplet capture efficiency to the water circulation rate in a tower. COOLDECK’s drift eliminators are specifically designed to achieve maximum drift removal efficiency in both crossflow and counterflow tower applications with various product options available to minimize pressure drop, drift loss, cost, or a combination of all three.

Panel Cooler

15,000 Per Piece

Aluminium Heat Dissipators

Get Price Quote

LAMIFLOW Heat Recovery System

Get Price Quote

Processes in the flexible packaging industry use a considerable amount of heat. Optimising this heat energy by recovering waste heat can reduce costs and thus significantly increase a convertor’s bottom line and hence an attractive investment option. The Lamiflow is a flat plate air-to-air heat exchanger where two air streams (exhaust and fresh air) cross each other, without coming in contact. The heat exchanger comprises multiple, thin, slightly separated plates with large surface areas that allows air flow passage for effective heat transfer, with minimal pressure drop. The sensible energy from warm exhaust air is transferred to the relatively cooler inlet air, without any mixing of the two air streams. This enables savings in energy spent to heat up fresh air from ambient temperature to the required temperature.

Heat Transfer

Get Price Quote

We are offering heat transfer. Duct serves the purpose of undisturbed surrounding complete panelized instrument for electric input digital voltmeter, ammeter & temperature indicator to determine average heat transfer coefficient calculate & plot variation of local heat transfer coefficient along the length of the tube.

heat recovery wheel

Get Price Quote

Airpac’s Air Handling Unit combination With Seibu-Giken's Hi-Panex-ION Total / Sensible Heat Exchanger Energy Recovery Wheel as name suggests, uses ION power to recover energy leading to more energy saving while achieving comfortable Air-conditioning. In a typical installation, the wheel is positioned in an Air Handling Unit so that it is divided into halves of Supply and Return Air Flow in counter flow directions with respective Filters, Heat Exchangers & Centrifugal Fans section to give Highest Level Performance .

Tubular Recuperator

Get Price Quote

Air Cooled Condensers

250,000 Per Piece