Vertical Accumulators

250,000 Per Piece

Crimped Fin Tube

Get Price Quote

Best Deals from Heat Exchangers

Reboiler heat exchanger

Get Price Quote

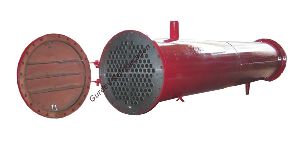

Shell and tube heat exchangerShell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned, etc. Shell and Tube heat exchangers are typically used for high pressure applications (with pressures greater than 30 bar and temperatures greater than 260°C).This is because the shell and tube heat exchangers are robust due to their shape.There are several thermal design features that are to be taken into account when designing the tubes in the shell and tube heat exchangers.

Heat Exchanger

Get Price Quote

The heat required for evaporation is supplied by low pressure steam. The advantage is the utilization of generally available utility steam thus saving in other power cost. In the shell and tube heat exchanger type of our design, the LPG liquid is passing though the SS tubes and the steam is circulated around the tubes. A cross flow is maintained to ensure high heat transfer. Higher differential temperature results into higher co-efficient of overall heat transfer, thus making the unit compact compared to hot water circulation vapouriser unit. Steam enters the heat exchanger at top and return steam with condenset returns from bottom. Liquid LPG enters at bottom and vapour comes out from top. The steam is maintained at 2.5 bar per sq. cm pressure. If available, steam is at high pressure it needs to be reduced to 2.5 bar using a pressure regulator. The steam flow required is controlled by temperature sensor. If the load on LPG vapouriser reduces, the flow of steam also reduces suitably. This interlocks ensure saving of steam. The sensor senses the temperature of outgoing vapour. If vapouriser load decreases vapour temperature increases, and thereby reduces steam supply. Other interlocks includes: 1. LPG liquid supply controls based on pressure of the vapour after primary regulator. If consumption reduces this pressure increases cutting off the solenoid valve in the liquid supply line. As the pressure drops to set limit, the solenoid valve opens again. 2. A thermostatic control ensures that if the temperature in the shell is less than the set limit, LPG liquid will not be supplied to the unit. Indicating lamps are provided on control panel show the status. Safety relief valve is provided on the vapour outlet line ensures that the pressure in the heat exchanger does not rise beyond safe limit.

coaxial heat exchanger

Get Price Quote

High Performance Coaxial Condensers are distinguished by a special design of the flow path. The counter flow principle for improved heat transfer is applied.

Shell and Tube Condenser

Get Price Quote

We make Horizontal Shell and tube ammonia condenser, which are available in different capacity ranging from 5TR to 400 TR.A shell and tube condenser (heat exchanger) is the most common type of heat exchanger used in refrigeration industry.Shell and Tube Condensers are having two divisions one is shell and other is Tubes. Here water runs through the tubes, and ammonia vapor flows over the tubes (through the shell) to transfer heat between the two fluids. For this purpose seamless/ERW or Rolled shell are used for shell. And Seamless/ERW tubes are used for Tubes. Different Pass Arrangements are made by providing baffles in the water heads, Like Two, four, six and eight pass designs are common because the fluid can enter and exit on the same side. This makes construction much simpler and Helps to limit the tube Length.The ammonia vapors enter the shell and get condensed by rejecting the heat to the circulating water in the tubes there are Baffles directing flow through the shell side so the vapor does not take a short cut through the shell side leaving ineffective capacity.These shell and tube condensers are tested at a hydrostatic pressure of 27 kg/sq. cm gauge (380 psig). We also make shell and tube condensers with SS tubes and SS water heads where the water is saline or very hard so the tubes can be cleaned easily with chemicals.

Polypropylene Cooling Tower Nozzles

Get Price Quote

10 Piece(s) (MOQ)

We Sgct Manufacturing Various Types Of Nozzle As Per Requirement & Base Upon Design, Pressure Required

Condenser Tubes

Get Price Quote

Condenser tubes in annealed and pickled, bright annealed, mill finish and polished conditions. One of our client from Saudi Arabia says that Trident Steel always has the quality inventory to cover our needs and the personnel that ensures it gets to us on-time, every time.

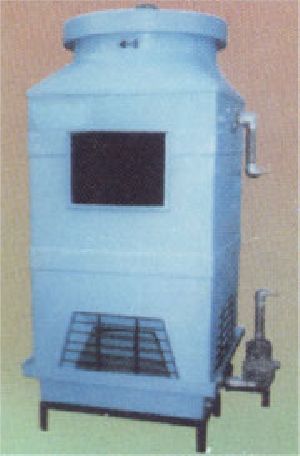

Cooling Tower

Get Price Quote

blanking panels

350 Per Piece

5 Piece (MOQ)

Static Mixer Heat Exchanger

Get Price Quote

cooling tower drive shafts

Get Price Quote

drive shafts in hot dip galvanized steel and stainless steel grades. The couplings are normally of cast iron. Cast stainless steel Grades are available upon request. The drive shafts are suitable for fans ranging from 8’ to 33’diameters . The drive shafts are tublar floating types and have flexible flanged couplings at both gear and motor ends , to compensate for any misalignment . The flexible elements are neoprene bonded metals. The length of the drive shafts are as per the cooling tower requirements. The drive shafts are dynamically balanced confirming to ISO 1946 Grade 6 prior to dispatch.

Cooling Tower

Get Price Quote

Available from 5 TR to 5000 TR Round Bottle Shaped (PC Series) Square Shaped Module (PS Series) Modular Design with high efficiency

Rcc Cooling Tower

Get Price Quote

Available In Induced Draft Cross & Single Flow Design, Induced Draft Cross & Double Flow Design and Induced Draft Counter Flow Design Cooling Towers : CLASSES: Class 9R (16 models), Class 10R (16 models), Class 15R (16 models), Class 18R (8 models) , Class 500R (12 models), Class 900 (12 models), Class 400R (12 models). There are a total of 92 models available under single cell configuration. Multi-cell configurations are provided to offer flexibility of operations and also to meet increased cooling requirements. These Cooling Towers are supplied in Reinforced Cement Concrete (RCC) construction and are case specific. Details provided on request for quote.

Double Door Combination Cooler

Get Price Quote

Double Tubesheet Heat Exchanger

Get Price Quote

We are offering double tubesheet heat exchanger. Total qty.: 16 nos. (exotic materials) shell & dish: sa 240 tp. 304l sa 516 gr. 70 tube: sb 622 n10276, sb 163 n06600, sb 163 n08800, sb 165 n04400, sa 789 s32750 & sa 312 tp. 304 flange: sa 266 gr. 2, sa 336 f 304l & sa 350 lf 2 tube sheet: (sa266gr.2+sb575 10276), (sa266gr.2+sb 168 n0660), (sa266gr.2+sb409 n08800), (sa266gr.2+sb127 n04400), (sa 350 lf2+sa240 s032750) & (sa266gr.2+sa240 s032750). Third party inspection: ibic engineering, lloyd's register asia & ibr

Heat Transfer Lab Equipments

Get Price Quote

Heat Transfer Lab Equipments, engine lab equipments

Air Aftercoolers

Get Price Quote

The unit is a shell and tube heat exchange with M.S. shell and Copper tubes. In case of Horizontal after cooler the water passes through shell over the tubes carring hot compressed air. There is a moisture separator provided at the out let of the cooler which removes the oil and water droplets formed due to cooling.

Vortex Tube Panel Coolers

25,000 Per Piece

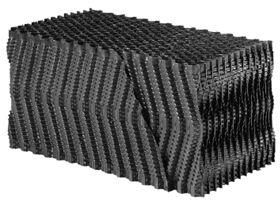

Cooling Tower Fills

Get Price Quote

Over the past three decades, COOLDECK has established itself as one of the leading manufacturer of cooling tower Components. Fills, drift eliminators, fans and nozzles for both crossflow cooling towers as well as counterflow cooling towers. Our products have been installed in across the cooling tower consumer spectrum including power, industrial and HVAC segments. We bring to you a combination of our functional knowledge of cooling towers along with deep expertise in polymer engineering and top that off with superior pre and post sales service in the cooling tower field. You can count upon COOLDECK to not just deliver products but assist you with cooling tower performance and upkeep issues.

Hot Plates

Get Price Quote

We offer hot plates. Hot plate moc : thick gi with iron plate top. Temp. : max 400 o c control : 3 heat control switch energy regulator control thermostatic control

Silent X-Stream Panel Coolers

Get Price Quote

The Silent X-Stream™ Frigid-X™ Panel Cooler series for electronic control panels provide a low cost method of both purging and cooling electrical and electronic control panels by using a stainless steel vortex tube to create cold air from ordinary compressed air. Utilizing a hot and cold end muffling kit the unit is made extra quiet to under 64 dBA depending on capacity. The hot end muffler also acts a "heat guard" - you can actually wrap your hand around it without feeling much heat. The hot air is exhausted safely underneath the hot end muffler. The Silent X-Stream™ Frigid-X™ Panel Cooler series are compact and can be installed in minutes through a standard electrical knockout. There are virtually no moving parts. Features Low in cost Compact No CFC's Fast installation Stabilize enclosure temperature and humidity Virtually maintenance free (No Moving Parts) Mounts in a standard electrical knockout Stops heat damage and nuisance tripping Eliminates fans and filters Prevents dirt contamination by keeping enclosure at positive pressure Units applicable to all environments including high temperature to 200°F

ERW Boiler and Heat Exchanger Tubes

Get Price Quote

Size Range: ½” od to 4” OD, W.th. 1.6mm to 5mm Grade: BS: 3059 Gr.320ASTM A 214Also available AIR HEATER TUBES as per BS: 6323 Part V

Aluminium Heat Dissipators

Get Price Quote

Cooling Tower Spare Parts

Get Price Quote

Cooltech Cooling Equipments uses high quality cooling tower spares like Rotary Sprinklers, PVC Fills, Fan Assembly and FRP Casings for Cooling towers. Cooltech is also a supplier of Cooling tower spares contact 9322274824 to order any of these spares which are available in different sizes for different capacity cooling towers.

tube type condenser

Get Price Quote

We can supply both Shell and Tube type Condenser. These shell condensers, tube condensers are designed specially, as per the heat load, for the vapour to travel a longer distance for effective condensation.

heat recovery wheel

Get Price Quote

Airpac’s Air Handling Unit combination With Seibu-Giken's Hi-Panex-ION Total / Sensible Heat Exchanger Energy Recovery Wheel as name suggests, uses ION power to recover energy leading to more energy saving while achieving comfortable Air-conditioning. In a typical installation, the wheel is positioned in an Air Handling Unit so that it is divided into halves of Supply and Return Air Flow in counter flow directions with respective Filters, Heat Exchangers & Centrifugal Fans section to give Highest Level Performance .

Aluminium Fins

500 Per Square Feet

Cooling Nipples

20 Per Piece

Tubular Recuperator

Get Price Quote