Heat Sink Parts

Get Price Quote

Heat Exchangers

Get Price Quote

Involved in delighting our customers, we bring forth a vast collection of Heat Exchangers. As an eminent figure, our wide array consists of different sizes and designs. Their quality is matched with the prescribed parameters of quality by industry. They have a high demand among our customers due to their low maintenance and high reliability. They can be availed from us at an affordable price. Details : Shell and Tube heat exchangers are the most common type of heat exchanger used in oil refineries and other large chemical processes, and is suited for higherpressure applications. We manufacture different types of heat exchangers as per TEMA class R, C, & B.Salient Features : Designed and Fabricated as per IS:2825, ASME Sec VIII Div 1 & 2, TEMA Codes & Standards Material of Construction - SS304, SS304L, SS316, SS316L, Duplex Steel or Carbon Steel Capacity - Heat Transfer 1m2 - 60 m2 or as per clients requirement Operating range, Pressure – full vacuum to 10 Kg/cm2 Types - Fixed Tube, U-Tube, Single Pass, Multiple Pass, Floating Head, Vertical or Horizontal Shell & Tube Heat Exchanger

Best Deals from Heat Exchangers

Heat Exchangers

80,000 Per Piece

1 Piece(s) (MOQ)

we design and manufacture most reliable and wide range of heat exchangers with a vision to provide heat transfer solution to everyone and everywhere. Our heat exchangers play a vital role in the operations and design of numerous machines such as air conditioning systems, heating systems, power generators, vehicles, refrigerators, oil rigs, and various engineering and chemical processing systems. The processes of waste heat recovery within industrial settings also utilize heat exchangers.

FRP FAN STACK COOLING TOWER SPARES

Get Price Quote

Jet Cooler

Get Price Quote

Heat Exchangers

Get Price Quote

We manufacture Shell & Tube type Heat Exchanger of any capacity using Codes like TEMA, our in house machining / drilling facility help us to maintain the accuracy and fast delivery. Our expertise are in SS, CS, Copper, High Nickel martial. Besides shell & tube we manufacture fins type HE for air/ liquid application in any size and any type of material. Our specially designed condenser's coils are usually made of copper tubes and aluminum fins. This helps it to transfer heat as rapidly as possible and demand minimal cleaning for the better transfer of the heat.

INDUSTRIAL TUBE HEAT EXCHANGER

100,000 Per Pieces

Cooling Tower

Get Price Quote

NEC Inducted draft cooling Tower carefully engineered spray system to anssures maximum cooling capacity per cubic foot of Tower Volume. Complete utilization of tower area is achieved by locating specilly designed spray nozzles of proper size in a pattern predetermine by test & experience to assure the most effective cooling performance. Application : Airconditioning & Refrigeration system Diesel generator sets & Air Compressors Plastic injection & blow moulding machines Chemicai & Pharmaceuticais industries. Other water cooler industrial process. Salients Features : Direct-driven axial fan. Verticle induced-draft counterflow. Highly efficient honeycomb PVC fill. Leak-proof FRP basin. Hot dip galvanised MS supporting structures. Modular, light-weight and long lasting construction. Corrosion-resistant and fire-retardant. Versatile applications.

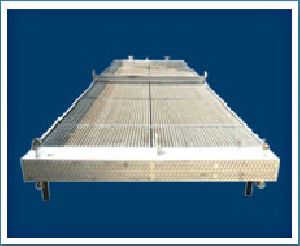

Air Cooled Heat Exchanger

Get Price Quote

Heft Engineers are specialized in to design and manufacturing of AIR COOLED HEAT EXCHANGER, using in-house manufactured finned tubes. These heat exchangers offer following advantages over other conventionl & crimped type finned tube Heat Exchangers. More surface area per square feet of heat exchanger Lower air resistance, resulting in less power to deliver the requires C.F.M. Reduction in number of tubes for given B.T.U. transfer per rate area, resulting in fuel saving Light weight easier handling More fins per inch can be incorporated on entire tube length The combination of low friction air loses/ high air velocity and maximum heat transfer per square feet of face area results in extremely high heating or cooling capacity of heat exchanger in a given space. The company has its own fining facilities, where finned tubes with various configuration and in variety of materials are manufactured. Available in 'G', 'L' plain & crimped configuration. The finned tubes can be assembled to performance requirement of your specific application. Typical industrial application where HEFT AIR COOLED HEAT EXCHANGERS are in operation.

Air Heat Exchangers

Get Price Quote

Heft Engineers are specialized in to design and manufacturing of AIR COOLED HEAT EXCHANGER, using in-house manufactured finned tubes. These heat exchangers offer following advantages over other conventionl & crimped type finned tube Heat Exchangers. More surface area per square feet of heat exchanger Lower air resistance, resulting in less power to deliver the requires C.F.M. Reduction in number of tubes for given B.T.U. transfer per rate area, resulting in fuel saving Light weight easier handling More fins per inch can be incorporated on entire tube length. The combination of low friction air loses high air velocity and maximum heat transfer per square feet of face area results in extremely high heating or cooling capacity of heat exchanger in a given space.

air cooled after coolers

Get Price Quote

Heat Exchangers

45,000 Per unit

Heat Exchanger

Get Price Quote

We deal in an array of high performance heat exchangers that are made of top graded material. Heat Exchangers manufacturer are made as per client requirements in terms of area, length and type. " For area, the heat exchangers are available from 25 sq. m. to 500 sq. m. and for length it is available upto 8 meters. Heat Exchangers are available in 2 types viz. single pass and multiple pass." Heat Exchangers available in two types, which is single pass and multi pass. The heat exchangers are manufactured as per TEMA and U tube bundle for re-boiler. The tubes attached to it are expanded or seal welded.

Heat Exchanger

35,000 - 1,500,000 Per Piece

Heat Exchangers

Get Price Quote

We are engaged in manufacturing and supplying of Heat Exchangers from Maharashtra, India. Our offered Heat Exchangers have a varying capacity from 1sq. Mtrs to 150 sq. Mtrs. We ensure customer satisfaction by passing the Heat Exchangers through stringent quality checks. Owing to our efficient logistics network, customers can rely on us for delivering small or bulk orders of the Heat Exchangers within the stipulated time.Details : Shell & tube type heat exchanger U tube heat exchanger Floating head type heat exchanger Double tube sheet type Double groove & expansion type

GI Heat Recovery Units

500,000 Per Piece

Aluminium sheet heatsink with mounting pins

Get Price Quote

Aluminium sheet heatsink with mounting pins

Heat Exchangers

Get Price Quote

Heat Exchangers, Storage Tanks, oil nozzle, Modulating Burner

Air Cooled Condenser

Get Price Quote

Air Cooled Condenser, Heat Exchangers, temperature control equipment

aluminum heat exchangers

Get Price Quote

aluminum heat exchangers

Heatsinks

Get Price Quote

Heatsinks, Ferrule, Copper Cable Lugs, Perforated Sheets

Cooling Tower Drive Shaft

Get Price Quote

Cooling Tower Drive Shaft, Fabrication Service, Cooling Tower Spare Parts

Reboiler heat exchanger

Get Price Quote

Reboiler heat exchanger, Paddle Agitator, Propeller agitator

Heat Sinks

Get Price Quote

Heat Sinks, Automobile Parts, Copper Cable Lugs, Mounting Box

Industrial Heat Exchangers

Get Price Quote

Industrial Heat Exchangers, Industrial Tube, Oil Coolers

Heat Sink

Get Price Quote

Alternator, Starter Motor, Junction Box, Castings

anodized extruded heat sinks

Get Price Quote

anodized extruded heat sinks, Crystal Dome Sticker, printing aluminum plate

Intercooler

Get Price Quote

Intercooler, Heat Exchanger Tubes, Heat Exchangers, Tube Heat Exchanger

PVC Cooling Tower Fills

Get Price Quote

PVC Cooling Tower Fills, Dry Cooling Tower, Cross Flow Cooling Tower

Heat Sink

Get Price Quote

Metal Products, precision sheet metal component