Heavy Duty Shearing Machine

Get Price Quote

We have carved a niche in this industry for offering Geared Heavy Duty Shearing Machine to the patrons. These machine is designed for manual cutting of hard sheet metals. It can cut strips, irregular shapes or slit sheet of steel and other materials. It has improved functional facilities and its convenient in operation. These are checked over the grounds of quality stages to ensure the delivery of defect-free range to the clients end.

Variable Rake Angle Hydraulic Shearing Machine

Get Price Quote

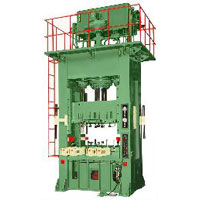

This fully hydraulic shearing machine is very versatile, reliable and efficient, designed and built to high standard to meet the requirement of precision sheet and plate working applications. Fast and accurate motorised back gauge with front digital readout is a standard with all models of this machine. The back gauge travels on precision lead screw. The machine also features: · Over-driven moving beam with two cylinders operating in series for even cutting. · Mono block DC solenoid valve ensures a smooth reversal hydraulic system. · Rake angle can be varied by pre selection through a selector switch to permit shearing higher thickness than normal capacity. · Front operated rake angle adjustment of 0.5 degree to 2.5 degrees allows optimum rake angle setting required to produce perfect cut with minimum twist and bow. · Top beam is guided by four point roller guides. It is equipped with replaceable hardened liners. · Quick and easy blade clearance setting by calibrated levers. · Individual hydraulic hold downs to ensure perfect cutting. · Shadow line indicator is useful for cutting on scribed lines. · Safety finger guard allows the operator to cut the material close to the cutting edge. In addition to all the above features, the machine is supplied complete with electricals, fine stroke adjustment rod with limit switches, front sheet supports, squaring arm on left end with steel rule and disappearing stop, hardened transfer bars mounted on table, four edge HCHC shearing blade. This model of the hydraulic shearing machine is available in cutting lengths of 1600, 2650, 3150 and 4150mm with cutting thickness in mild steel with normal rake angles of 6, 8, 10, 13, 16 and 20mm capacities.

Best Deals from Hydraulic Shearing Machine

variable rake angle hydraulic shears

Get Price Quote

Ram & Table designed with inclined member and box type structure for maximum strength. Positive holding of Hyd. Hold downs avoids slippage of sheet during cutting stroke. HCHCr Blade suitable to MS & SS. Hardened Transfer bars. Front gauging by disappearing stoppers mounted on front squaring arm. SPECIAL FEATURES The stable robust, all welded steel frame from ultrasonically tested plates are of top quality. Ramand table designed with special inclined member and box type structure for maximum strength. The top beam is guided by three point roller with replaceable hardened liners for least wear.This eliminates lubrication of guides. Roller guide made of hardened & ground bearing steel to provide better quality of cutting for a long time. Rake angle can be varied to permit shearing of higher thickness than nominal capacity and facilitating distortion free shearing of thin sheets. The fastest and easiest way of blade clearance setting without need of feeler gauge, which helps Burr-free edges. Positive holding by hydraulic holddowns before shearing avoids slippage of sheets and independent operation of holddowns for clamping of sheet helps checking of mark without taking shear stroke. Front gauging by disappearing stoppers mounted on left squaring arm. Robust, heavy & accurateback gauging to set cutting width. Hydraulic cylinder are designed with both low and high pressure sealing, Hard chrome plated rod also with special type guide for long life without leakage. Hydraulic components of international quality assembled in our own factory with specially designed compact manifold STANDARD ACCESSORIES Main Drive motor Electric Control Panel Operational Console Pre selector switch to adjust rake angle Lever operated blade clearance with calibration Fine stroke adjustment rod with limit switch Front sheet support Squaring arm on right end with steel rule Hardened transfer bar mounted on table Hold down cylinders Shadow light Indicator Four edge HCHCR / HCSR blade interchangeable & suitable to shear mild and St. Steel Manual back gauge OPTIONAL ACCESSORIES Second squaring arm on left side Motorised back gauge with DRO NC back gauge with ball screw Front support with rolleraccording to required length Rear sheet support Ball transfer table Degree protector for angular cutting Stroke counter Design with throat depth First fill of hydraulic oil

Manual Hydraulic Guillotine Shear

Get Price Quote

1 Piece(s) (MOQ)

variable rake angle hydraulic shears

Get Price Quote

Range : 3 mm to 25 mm Length : 1250 mm to 6000 mm Ram & Table designed with inclined member and box type structure for maximum strength. Positive holding of Hyd. Hold downs avoids slippage of sheet during cutting stroke. HCHCr Blade suitable to MS & SS. Hardened Transfer bars. Front gauging by disappearing stoppers mounted on front squaring arm. SPECIAL FEATURES The stable robust, all welded steel frame from ultrasonically tested plates are of top quality. Ram and table designed with special inclined member and box type structure for maximum strength. The top beam is guided by three point roller with replaceable hardened liners for least wear.This eliminates lubrication of guides. Roller guide made of hardened & ground bearing steel to provide better quality of cutting for a long time. Rake angle can be varied to permit shearing of higher thickness than nominal capacity and facilitating distortion free shearing of thin sheets. The fastest and easiest way of blade clearance setting without need of feeler gauge, which helps Burr-free edges. Positive holding by hydraulic holddowns before shearing avoids slippage of sheets and independent operation of holddowns for clamping of sheet helps checking of mark without taking shear stroke. Front gauging by disappearing stoppers mounted on left squaring arm. Robust, heavy & accurateback gauging to set cutting width. Hydraulic cylinder are designed with both low and high pressure sealing, Hard chrome plated rod also with special type guide for long life without leakage. Hydraulic components of international quality assembled in our own factory with specially designed compact manifold STANDARD ACCESSORIES Main Drive motor Electric Control Panel Operational Console Pre selector switch to adjust rake angle Lever operated blade clearance with calibration Fine stroke adjustment rod with limit switch Front sheet support Squaring arm on right end with steel rule Hardened transfer bar mounted on table Hold down cylinders Shadow light Indicator Four edge HCHCR / HCSR blade interchangeable & suitable to shear mild and St. Steel Manual back gauge OPTIONAL ACCESSORIES Second squaring arm on left side Motorised back gauge with DRO NC back gauge with ball screw Front support with rolleraccording to required length Rear sheet support Ball transfer table Degree protector for angular cutting Stroke counter Design with throat depth First fill of hydraulic oil

Heavy Duty Shearing Machine

Get Price Quote

- Machine made of M.S. sections and flats. An all steel body, nut bolted and welded structure - Used for cutting EN-45 steel spring flats - Equipped with alloy hardened cutting blades - Shaft and pinion are of forged steel. Gears of Cast Iron (hobbing machine cut) - Speed: 38 strokes a minute - Operation by clutch system, operated by a foot lever - Drive through a 5 HP electric motor with necessary pulley and 'V' belts - Capacity to cut maximum 200 mm wide x 20 mm thick EN-45 flats

Hydraulic Shearing Machine

Get Price Quote

crankshaft grinders, Crankshafts, Forging Hammer

Hydraulic Shearing Machine

Get Price Quote

Single Stage Compressor, Arbour Press, SPRING CONTROLLED ARBOR PRESS