Ibr Steam Boilers

Get Price Quote

IBR Steam Boiler

Get Price Quote

Manufacturer & Exporter of Steam Boiler & Accessories water wall panel, Air Pre Heater, Economizer,

Best Deals from IBR Steam Boiler

IBR Steam Boiler

Get Price Quote

ENERGYPACK -IBR Steam Boilers in Maharashtra, manufactured by us are designed as per latest Indian boiler regulation & others code like BS or ASTMA. Capacity from 500 kgs/hr to 14,000 kgs/hr for the process industries.

IBR Steam Boiler

4,000,000 Per Set

1 Set(s) (MOQ)

We Manufacture SMOKE TUBE or FIRE TUBE Oil Gas Fired Steam Boilers up to capacity of 16 TPH with steam pressure up to 25 Bar. The Boilers are Manufactured under Inspection of IBR ( Indian Boiler Regulation) or alternatively can also be manufactured under LLOYDS Register ( LR ) , BVQI or any other Inspection Agency authorised by IBR and acceptable to customer.

Oil Gas IBR Steam Boilers

Get Price Quote

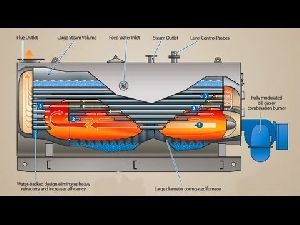

Type : Three pass horizontal, smoke tube, fully wetback, packaged boiler, conforming to the latest revisions of Indian Boiler Regulations. (IBR) Capacity : 1000 to 25000 kg/h F & A100º C Working Pressure: 10.54 / 14.5/ 17.5kg/cm2 (g) and above. Fuel : LDO / FO / Gas / Dual Fuel (Oil cum Gas) Thermal Efficiency : 88 ± 2 % without heat recovery unit and 92 ± 2 % with heat recovery unit based on NCV of fuel oil. Burner : Fully automatic pressure jet (high - low / stepless modulation ); indigenous / imported burners. The combustion chamber (furnace) forms the first pass in which the fuel is atomized, combusted and radiant heat transmitted to the water contained in the shell, submerging the furnace, reversing camber and smoke tubes. The hot flue gases are diverted through the internal reversing chamber (wetback) and subsequently to the second and third pass of tubes transferring the convective heat to the boiler. The boiler is of Class 1 fusion-welded construction. Burner & Boiler Controls The burner programmer ensures an automatically controlled programme for start-up, firing, shutdown and restart of the boiler based on measurement of boiler pressure. Necessary interlocks are provided for safe operation. The water level is controlled through Mobrey type dual controller which is a magnetically operated water level controller of vertical type in a float chamber and is externally mounted on the boiler. One switch of the dual controller operates the electric feed pump on/off. The second switch cuts out or locks out the burner in case of low level of water and at the same time operates a low level alarm. The boiler is provided with one high pressure cutout switch and one additional pressure switch for high/low, or continuous modulation of operation. Salient Features MAXITHERM has adopted the modern concept of eccentrically located furnace with smoke tubes arranged in a staggered manner on one side of the furnace. The front and rear tubes and the furnace are accessible for inspection and maintenance. Generously proportioned furnace with large furnace volume ensuring; Maximum possible absorption of radiant heat. Avoidance of flame impeachment on the rear of the furnace. Prevention of clinker formation. Enhanced life of furnace. Adequate water and steam spaces enable the boiler to meet fluctuating loads with out appreciable fall in the operating pressure. This also ensures prevention of priming, foaming and carryover of the boiler water into steam pipelines and further ensures steam with high dryness fraction. The eccentrically located furnace has the following advantages :- Easy accessibility to the outer surface of furnace for inspection and scale removal. Possibility of providing single smoke box, which when opened makes all smoke tubes accessible for cleaning. The burner is mounted directly in font of the furnace, facilitating opening of the front door to clean the tubes without disturbing the burner.

IBR Steam Boiler

Get Price Quote

1) Fully automatic instant steaming. 2) Easy operation fail proof system. 3) Record efficiency. 4) Packaged models in unitised design.

Ibr Steam Boilers

Get Price Quote

Ibr Steam Boilers, Heating Equipment, Pressure Vessels

Ibr Steam Boilers

Get Price Quote

Ibr Steam Boilers, Air Heaters, boilers accessories, Gas Burners