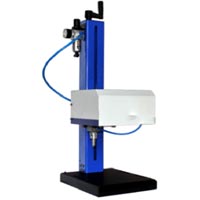

Impact Press

Get Price Quote

We are offering impact press. we are the one stop shop in market for availing precision engineered standalone impact press machine. Impact press machine, available with us, is robustly constructed in accordance with high quality standards. The standalone impact press machine is very easy to operate and is preferred for its user-friendly operations. details easy - to - adjust impact force.automatic compensation for different workpiece thickness ( note : airline pressure is only compressing the spring - not for determining impact force).higly versatile : ideal for light assembly work and for sheet metal work (rivetting, flaring, piercing, shearing, bending ... Plus many more operations).out put speed matches speed of manual loading.lowest rejections - even in precision jobs.far longer tool / die life !adaptable for automation with approxiate fixtures tools and dies.tools with cylindrical shanks are clamped by a collet in tool-holder.arm can be set and clamped at any height on the column.fine-ground working table surface with t-slots for speedy fitting of work - holding fixtures.all sliding parts are made of selected steel hardened and ground.

Hand Operated Impact Press

Get Price Quote

We are celebrated name based in Mumbai(India) and actively engrossed in making available high quality products at the most reasonable prices. Interested buyers can place orders with us, timely delivery of the same are our foremost concern.

Best Deals from Impact Press

impact extrusion presses

Get Price Quote

The Impact Extrusion Press is used to extrude aluminium container drawn from slug after lubrication in single stroke. As per all automatic high production machines, precision built for continuous operation over long periods with an absolute minimum of attention and down time. Our Horizontal Extrusion Presses have a carefully designed main frame built for stronger than normal usage demands. The rigid construction reduces deflection to an absolute minimum and even at the higher speed these Presses are stable in operation.

Foot Operated Impact Press

Get Price Quote

Foot operated Impact Press model AMI-10 equipped with handchrome pillar, T slotted base for work holding. The precise control of striking load, the adjustable arm and wide throat permit using the press in various industries having maximum adjustable pressure upto 1000Kgs. working surface of table 150 x 100 mm, throat centre distance 130 mm.

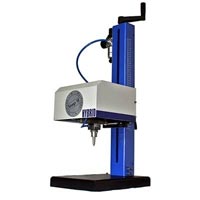

Impact Press

Get Price Quote

Impact press with adjustable striking load, the adjustable arm and wide throat permit using the press in various industries like electrical control equipment, switch gear, domestic appliances, radios, telephones, materials equipment, cycles, office equipment, ammunition, automobile ancillaries etc.

31/2 Ton Impact Press

Get Price Quote

31 / 2 Ton Impact Press, Encapsulated Coils for Valves

spring controlled impact press

Get Price Quote

spring controlled impact press, Hydraulic Cylinder, Hydraulic Press

Impact Press

Get Price Quote

Impact Press, Wood Turning Lathe, Pillar Fly Press, Hydraulic Press Brake

impact presses

Get Price Quote

impact presses, marking tools, Hand Punches, automatic rotary numerators