Die Induction Hardening Service

Get Price Quote

Die induction hardening service utilizes electromagnetic induction to heat the surface of dies, followed by rapid quenching to enhance their properties. This process strengthens the dies, increasing wear resistance and durability, crucial for precision manufacturing industries like automotive, aerospace, and tooling. By selectively hardening the surface, the dies maintain their core toughness and dimensional accuracy. This service significantly improves the performance and lifespan of dies, ensuring reliable and consistent production processes, ultimately enhancing productivity and product quality.

Induction Hardening

Get Price Quote

The company has a complete integrated heat treatment infrastructure. The journals are induction hardened by inserting the coils around the journals & passing heat at 800°C. The hardness of the journals is achieved to a depth of 5 mm. There is also a provision to fillet harden the journals as per customer requirement. We maintain an average hardness as per OEM specification of 56-62 HRC. The company has achieved 10 million cycles in crankshafts manufactured without any breakage on the same, tested & approved by ARAI(Automotive Research Association of India) which is a Government of India company.

Looking for Induction Hardening Service Providers

Induction Hardening

Get Price Quote

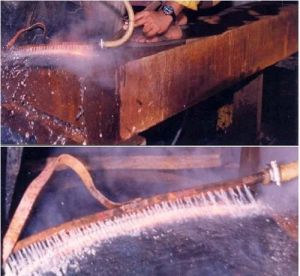

Induction Hardening, Cement Mill Water Spray System