Ductile Iron Castings

100 - 110 Per Kilogram

We are reputed manufacturer of ductile iron castings in India. In our foundry we make Ductile iron castings as per IS 1865 grade 400/12 ,500/7 etc.Minimum single piece 1kg to Maximum single piece upto 900 kg single pce.

CI High Pressure Gate Valve Body Casting

2,499 - 149,990 Per Piece

1 Piece (MOQ)

Best Deals from Industrial Casting

die casting services

Get Price Quote

We are having die-casting shop with machines ranging from 75 to 800 tonnes capable of producing components from 0.5 grams to 8.5 kg. Our fully automated closed loop die casting cells maintain history of process parameters for every shot. It achieves repeatability and quality in every shot by adjusting itself automatically to reach the set parameters.We have defined special process parameters and aids to achieve wall thicknesses as thin as 1.2 mm and as thick as 10 mm without problems. We utilize Control Plans + Process Parameter Sheets and die maintenance plan, spares for every item to eliminate production errors, improve surface finish and integrity of castings, to reduce wear and tear of die to enable timely dispatches.Proof machining is carried out on all machined areas during casting cycle. Traceability is maintained up to 3 years for on line inspection reports, material composition and our suppliers heat no.

heat resistance castings

Get Price Quote

With firm commitment to quality, we are able to offer our valued customers with Heat Resistant Alloy Castings. These parts are available in many sizes and specifications to meet the requirements of our customers. Our team of qualified professionals manufacture these parts by making use of superior quality raw-materials brought from the trustworthy vendors of the industry. Owing to its non-corrosive nature and durability, these Heat Resistant Alloy Castings are widely demanded by our clients. Advantages of Heat Resistant Alloy Castings Can be satisfactorily utilized in different specialized usages, advanced opposition to hot gas corrosion even in existence of some sulphur. Can be efficiently utilized for resisting thermal shocks of cooling and heating. Resistant to oxidation and carburization at high temperature. Come with advanced combination of creep strength as well as ductility, resistance to corrosion.

ISO 1161 Corner Castings (Pocket)

1,900 Per Piece

50 Piece(s) (MOQ)

We manufacture Steel, Stainless Steel standard ISO Corner castings and fittings for Containers. Bulk orders only.

Heavy Duty Cast Cable Saddle

Get Price Quote

Fix using countersunk wood screws For use with PVC covered 8mm conductor or for supporting air terminals when used in conjunction with wall mounted air bases. Can also be used with Glazing bar holdfast and Back plate holdfast stem

Lead Castings and Valves

Get Price Quote

We have expertise in the manufacturing of lead castings and anodes. We have facilities to manufacture single piece castings weighing up to 10 MT. and lead anodes as per the requirements of clients.

Hollow Valve Ball

60 - 2,000 Per Piece

25 pieces (MOQ)

We make hollowvalve balls for valve industries. Size from 1 inch to 8 inch

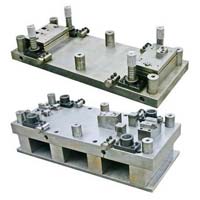

Aluminium Die Casting Molds

Get Price Quote

Designed to withstand adverse effects of abrasion and moisture, our Aluminium Die Casting Molds are of immaculate quality. Our company’s name figures in the list of prominent Manufacturers, Suppliers and Exporters of Aluminium Die Casting Molds from Maharashtra. The Aluminium Die Casting Molds we make available are manufactured in accordance with international quality standards and norms. We are capable of delivering bulk orders of the Die Casting Molds within stipulated time.

Gun Metal Casting

Get Price Quote

We are among the prominent gun metal castings manufacturers and suppliers all over india. Gun metal castings brought forth by the company, are available in various hardness, tensile strengths and dimensions. Gun metal castings are manufactured using high grade raw materials in compliance with international quality standards. Gun metal castings of our company are widely accepted in different industries for their brilliant surface finish. Gun metal castings are highly appreciated by clients for their tolerance capacity, dimensional accuracy and durability. Typical uses of gunmetal casting is pressure tight bearings, bushes, pumps and pump fittings, valves, valve bodies, and valve guides under corrosive marine conditions, gear and worm wheels, bearings for aero engines, diesel engines, electrical generators and rolling mills etc. Attributes easily affordable prices corrosion resistant finish high tensile strength longer service life various hardness dimensions accuracy tolerance capacity

Gate Valve Casting

Get Price Quote

Our wide product range comprises investment casting fittings, which are manufactured from high-grade stainless steel at our vendor base. These investment casting fittings are durable, corrosion resistant, and precision engineered and perfectly finished with superior shine. Our clients can avail these investment casting fittings from us in different sizes and dimensions as per their specific requirements.

Aluminum Sand Casting

290 - 320 Per Kilogram

Rate depend on pattern

Sand Casting

1,000 Per Kilogram

machined casting

Get Price Quote

100 Piece(s) (MOQ)

We are working with a team of deft professionals who manage the entire task proficiently and lay special emphasis on product packaging so as to ensure safe and secure deliveries. Our payment procedure is not only easy to operate but also guarantee secure transactions. In addition to this, it is featured with multiple options like cash payment, bank account transfer and more.

Sand Casting of Aluminium , Brass , Gun Metal

80 - 350 Per kgs

500 Kgs (MOQ)

High quality product from our highly experienced team to fullfill your requirement.

Gun Metal Casting

Get Price Quote

FERROUS METAL SHELL CASTING

Get Price Quote

Shell mold casting allows the use of both ferrous and non-ferrous metals, most commonly using cast iron, carbon steel, alloy steel, stainless steel, aluminum alloys, and copper alloys. Typical parts are small-to-medium in size and require high accuracy, such as gear housings, cylinder heads, connecting rods, and lever arms.

construction castings

Get Price Quote

aa aa These covers are manufacture concrete infill type, bolted, gasket and watertight and tamper proof manhole covers in grey iron and ductile iron. Available in grey and ductile iron Load Rating available: A15, B125, C250, D400, E600 and F900 Our load testing machine can test up to F900 Broad range of patterns available: 300 mm X 300 mm (11.81" X 11.81") clear opening to 1200 mm X 1200 mm (47.2" X 47.2") clear opening Manufactured to EN-124 standards patterns for North and South Europe available New patterns can be developed in six weeks

Die Casting

Get Price Quote

Molding Process: High Pressure Die Castings, Gravity Die Casting. Die Making: Die Material used- Hot Dies Tool Steel, Computer Simulation of Thermal Solidification Solid Modeling, Rapid Tooling using CADCAM. Molding Equipment: Cold Chamber Machine up to 2000 tons, including fully automatic machines. Hot chamber machines up to 60 tons. Furnaces: Oil Fired Furnaces, Tilting Furnaces, Electrical Holding Furnaces. FettlingCleaning Equipment: Trimming presses, Tumbling Vibratory Deburring & Grinding. Testing: Spectrometer, Chemical Wet Analysis, Microscope, Radiography, X-Ray, Hardness Tests, Tensile, Impact Testing, MoldCore Hardness Tests, Magna-flux Crack detector, LeakPressure Testing. Secondary Of Facilities: CNC, VMC, HMC & Conventional Painting, Powder Coating, Plating-Zinc, Nickel, Chrome, Tin, etc.

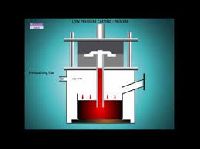

low pressure die casting

Get Price Quote

n die casting, molten metal is injected into a mold at high pressure. The pressure can range from about 1,400 psi to as high as 30,000 psi. By pressurizing the mold, the cast object will be more uniform and will display an attractive finish. In many cases very little or no post-casting machining is needed to complete the item. Pressure molding also provides for precise dimensional accuracy that is critical for parts used in products with interchangeable parts. Low pressure die casting is commonly used for larger non-critical parts. Whereas high pressure castings which are used for tight tolerance detailed geometry. High pressure die castings are able to maintain tighter tolerances and more detail than low pressure die casting because the extra pressure utilized is able to push the metal into more detailed features in the mold. High Pressure die castings have excellent surface finishes that are consistent dimensionally with precision features and minimum draft. There are two main die casting processes, and their use is dependent on the type of metal being cast:

Supercast Dairy Valve Investment Casting

450 Per Kilogram

Industrial Casting

Get Price Quote

Heavy Duty Cast Cable Saddle

Get Price Quote

We are offering heavy duty cast cable saddle. These are used with 8 mm conductor or for supporting air terminals when used in conjuction with wall mounted air terminal base.

aluminium motor body

Get Price Quote

CG offers IEC metric Frame single phase motors in aluminium diecast body construction. These motors cater to the needs of the global customer for light weight and efficient motors with improved ventilation. These motors are available in IP44 & IP55 enclosures.

stainless steel sand casting

Get Price Quote

We specialize in high quality pressure castings for pumps and pump products, specifically impeller castings, our expertise with steel, alloy steel, stainless steel.

HT Electric Motors

Get Price Quote

Gun Metal Casting

Get Price Quote

Manufacturer & Exporter of Gun metal CastingAcclaimed in the industry as a leading manufacturers, suppliers and exporters, we are engaged in offering our clients with a wide range of Gun Metal Castings. Our offered castings are designed and developed utilizing optimum – grade metals and allied components that are sourced from reliable vendors of the market. Also we are able to despatch our range on time to the customers. Gunmetal is also known as Red brass. It is a type of bronze – an alloy of copper (88%), tin (10%), and zinc (2%). Originally used chiefly for making guns, gunmetal was eventually superseded by steel. Gunmetal casts and machines well and is resistant to corrosion from steam and salt water and is used to make steam and hydraulic castings, valves, and gears, and also statues and various small objects, e.g. buttons. It has a tensile strength of 221 to 310 MPa, a specific gravity of 8.7, a density 8,719 kg/m3, and a Brinell Hardness of 65 to 74.Gunmetal can also mean steel treated to simulate gunmetal bronze. Bushings made of this metal are used in machinery.

High Chrome Castings

Get Price Quote

We are considered as one of the leading High Chrome Metal casting manufacturers from India. We offer finest quality High Chrome Steel Casting that is utilized in diverse industrial applications. Some of the chief attributers of High Chrome Casting are long life and high performance. High Chrome Castings can be obtained in unlike specifications and grades as per client�s requirements. Our High Chrome Casting meets the required British standards. Our range of High Chrome Casting is abrasion-resistant, that hammers in impact crushers and is available in steel case packing. Highlights DurabilityHigh strength Corrosion resistanceResistance to abrasion

Choke Casting

500,000 Per Piece

1 Piece(s) (MOQ)

heat resistant castings

Get Price Quote

Stainless Steels containing a combination of High Carbon, Chromium, Nickel and a few other specific elements, can be designed to exhibit: Resistance to oxidation (scaling) upto almost 1150o C, Good high temperature strength, High Resistance to sigma phase precipitation, Due to their larger grain size and superior creep properties, cast components outperform wrought components and are commonly used as parts of furnaces, radiant tubes, muffle liners and heat treatment trays.