magnetic core drilling machines

Get Price Quote

FULL WAVE CONTROL ELECTRONICS The electronic control ensures continuous adaptation of the motor output to the load during drilling. The advantages are high performance at low speed and a steady sequence. If load peaks should be too high, the electronic torque control will be activated in order to prevent tool breakage and avoidable damage. An active contribution to employee safety with machines. AUTOMATIC INTERNAL LUBRICATION Cutting oil where it is required. This principle always ensures the exact amount and even distribution over the entire cutting area. No dry running and overheating of the drill, no excessive use of coolant. Tool service life and work results will be significantly improved. OIL BATH GEARBOX KB Industries offers a wide range of highly efficient magnetic core drilling machines with powerful and durable motors. The spectrum ranges from 800 W to 2,300 W. They are designed for the high performance requirements of the magnetic core drill technology. KB Industries manufactures machines with multi-stage gearboxes, which are completely embedded in oil. KB Industries magnetic core drilling machines are robust and reliable. CARBON BRUSH WEAR CONTROL The machines of the Profi-PLUS class are provided with a new visual wear control for the carbon brushes. By replacing the worn carbon brushes in time, you will protect the motor of your machine from damage. SAFE ARRANGEMENT OF SWITCHES The large switches for motor and magnetic power are separated and safe to handle, i.e., confusion is impossible and accidents are prevented. Thanks to the construction of the switch, unintended actuation of the motor switch is prevented. INTERNAL CABLING KB Industries Magnetic Core Drilling Machines are safe to handle. Due to internal cabling, cables are protected against tearing-off. MAGNET AND MAGNET INDICATOR The load configuration and the reserves of the electromagnet are exactly adapted for the performance of the respective magnetic core drilling machine. The user is informed by a visual control. LED green: The magnetic adhesion meets the minimum requirements. LED red: The magnetic adhesion is not sufficient, because it is reduced due to low material thickness or a coat of lacquer, forge scale or zinc.

Special Purpose Machine

Get Price Quote

FOHMICS INDUSTRIAL MACHINERY manufactures and supplies Special Purpose Machines and our setup is situated in Mumbai, Maharashtra, India. We at FOHMICS INDUSTRIAL MACHINERY design and manufacture customized products used for various welding requirements. Below are someof customized Special Purpose Machines designed and manufactured by us.

Best Deals from Industrial Drilling Machine

Special Purpose Machine

Get Price Quote

Special Purpose Machine

Get Price Quote

We are offering special purpose machine, high volt transformer winding machine for transformer industries.

Radial Drill Machine

Get Price Quote

Paper Drilling Machine

Get Price Quote

cnc drilling machines

Get Price Quote

HSS Broach Cutters, Tct Cutters, Hss Cutters, Broach Cutter

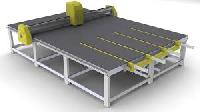

Glass Cutting Machine

Get Price Quote

Glass Drilling Machine

Get Price Quote

glass cutters

Drill Machine

Get Price Quote

Drill Machine, Air Compressor, Reciprocating Air Compressor

Drilling Machines

Get Price Quote

Pneumatic Grinding Machine, Piston Pumps, electric air compressor

Drill Machine

Get Price Quote

Drill Machine, Cutting Blades, Cutting Tools, Marble Cutter

Drilling Machine

Get Price Quote

Drilling Machine, Foam Glass, Refractory Cement, Aluminum Banding

Special Purpose Machine

Get Price Quote

Clamps, conduit clamps, Earthing Rods, Energy Saver, Trefoil Clamps

Drilling Cum Tapping Machine

Get Price Quote

Primary and Secondary Distributor Blocks, Compact Lubrication Pump

Drill Machine

Get Price Quote

Drill Machine, Angle Grinder, Cutting Machine, breaker machine

Drill Machine

Get Price Quote

Drill Machine, Cut Off Machine, Cutter Machine

Drilling Machine

Get Price Quote

Drilling Machine, Boring Machine

Special Purpose Machine

Get Price Quote

Sealing Machine