Vertical Boring Machine

Get Price Quote

Suitable for Automotive Engine Rebuilding - Boring head travels on Ground Guide Ways protected with bellows - Boring Head fitted with hardened alloy gears to give smooth feel and slide on columns - Mechanical Machine with 2 Speed Motor and Six Speed Gear Box - Optional: Machine with AC Drive instead of Mechanical Machine

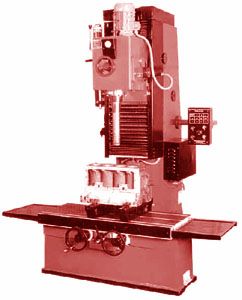

Multi Spindle Drilling Machine

Get Price Quote

These multi spindle drilling machines are mainly used in automobile industries for drilling holes in crankcase, cylinder head, connecting rod etc. The drill head is supplied with high pressure through coolant or external coolant depending on the application. The drilling feed is provided by a CNC table or a hydraulic table. The drills are guided in a mobile jig plate or a fixed jig plate depending on the application. The drills are mounted on to the spindle using an adjustable adaptor or a stub tool holder.

Best Deals from Industrial Drilling Machine

Deep Drilling Machine

Get Price Quote

Multiple-spindle drilling machines are used for mass production. These machines are great time savers where many pieces of jobs having many holes are to be drilled. Multi-spindle head machines are used in mechanical industry in order to increase the productivity of machining systems. The multiple- spindle drilling machine is a production type of machine. It is used to drill several holes in a work piece simultaneously, in a single setting. This machine has many spindles driven by a single motor and all the spindles are fed in to the work piece simultaneously. These machines may be either horizontal or vertical type. The drill heads consists of several spindles mounted on angular contact ball bearings and driven by a set of gears. For spindles wherein the center distance are very close needle roller thrust bearings are used. The drive to the spindle is by AC spindle CNC motor or by AC induction motor. The speed of the spindles driven by induction motor is varied by using variable frequency drive. The drill head is interchangeable. These multi spindle drilling machines are mainly used in automobile industries for drilling holes in crankcase, cylinder head, connecting rod etc. The drill head is supplied with high pressure through coolant or external coolant depending on the application. The drilling feed is provided by a CNC table or a hydraulic table. The drills are guided in a mobile jig plate or a fixed jig plate depending on the application. The drills are mounted on to the spindle using an adjustable adaptor or a stub tool holder.

Seed Cum Fertilizer Drill Machine

Get Price Quote

We offer seed cum fertilizer drill machine. Seed cum fertilizer drill machine is used to plant variety of crops like wheat, maize, millets, pulses etc. It is available in single top box and double top box (one of seed, other for fertilizer) having 891113 tynes & operates with minimum 25 hp tractor gill single top box 9 length (over all) 84" width from divider frame to linked 35" height (from ground level to seed drum top) 15" no of tyne (for rows) 9 no (forged pieces of 25 mm thick flat) wheel position adjustable 8" to 9" gear mechanism 18 teeth gear fitted on 1" dia shaft and 10 teeth gear fitted on m.s wheel no. Of dividersfeeder 9 no. Attached with seed drum wheel position adjustable m s 6 mm thick plate + flat adjustable covering 18 dia" feed mechanism (c I bodies) specially designed seed divider'sfeeders fitted at bottom base of seed drum and will be adjustable according seed body (frame): m s angle 50 x 50 x 6 mm m s flat 65 x 10 mm m s flat 50 x 10 mm body (sheet): m s 2.90 mm 10 gauge m s 2.00 mm 14 gauge prime mover driven with minimum 35 hp tractor and above output approx 1.5 to 2.5 acerhr weight 310 kg gill double top box 9 length (overall) 84" width from divider frame to linked 35" height (from ground level to seed drum top) 45" no of tyne (for rows) 9 no (forged pieces of 25 mm thick flat) wheel position adjustable 8" to 9" gear mechanism 18 teeth gear fitted on 1" dia shaft and 10 teeth gear fitted on m s wheel no of dividersfeeder 9 no attached with seed drum 9 no attached with fertilizer drum wheel position m s 6 mm thick plate + flat covering 18 dia" feed mechanism specially designed seed divider'sfeeders fitted at bottom base of seed drum and will be adjustable according seed body (frame): m s angle 50 x 50 x 6 mm m s flat 65 x 10 mm ms flat 50 x 10 mm body (sheet): m s 2.90 mm 10 gauge m s 2.00 mm 14 gauge prime mover driven with minimum 35 hp tractor & above output approx 2 to 2.5 acerhr weight 390 kg

HSS Core Drills

Get Price Quote

At the initial stages of using raw material for the production, our dedicated quality staff makes certain that the inputs used are of premium quality. Thus, our offered range is highly appreciated for the quality. Keeping pace with the contemporary market trends, we ensure on-time and safe delivery of the orders.

Pillar Drilling Machine

Get Price Quote

Parts Properly Balanced Prior Assembling of Main Gear & Pully Parts finished on imported Grinding M/c. All Moving Parts Finished to Close Tolerance. Main Spindle & Pinon are Made out of EN Forged Steel. Spindle Ram is made out of Alloy Steel.

Magnetic Core Drill

Get Price Quote

Drilling Tools

Get Price Quote

We always make use of quality raw materials for the production of our products as we comply with all set quality standards. For the utmost customer satisfaction, we are flexible in delivering the product range at the place agreed by the customers and that too in the set time.

Radial Drilling Machine

Get Price Quote

micro

Get Price Quote

Simple in its design, it's very powerful and stable in use!

horizontal line boring machine

Get Price Quote

Boring Bars with appropriate bearings, cones, extra supports and cutters 22 x 1300 mm and 60 x 2500 & 3000 mm Into-Bore Gauge (for measuring without removing boring bar) 35-105 mm and 100-210 mm Tool Grinder Extra Cutter Heads for 30 mm & 48 mm Boring Bars Extension for Boring Bar 260 mm Small Busing for extra support (specify diameter of boring bar) Boring Bar Sag Checking Attachment Bpring Bar Hand Feed Remote Control

angle head

Get Price Quote

We are offering angle head.

vertical fine boring machine

Get Price Quote

Vertical Fine Boring Machine is specially designed for fine and accurate machining of cylinder bores. Manufacturers ensures years of trouble free operation as every phase of manufacturer is under strict quality control. Base and column are of high grade casting. Boring head travels on a Hardened & Grounded finished guide ways column protected with bellows. Boring head is fitted with hardened alloy gears to give smooth feed and side on column. Controls are provided on one side of the machine on a comfortable position and easy operation. The Machine is supplied with the following standard equipment : Boring tool setting device complete with micrometer. Two tool holders for boring. Portable Grinder with suitable Grinding/Lapping Wheels. Two Block Jacks. Two Sets of Parallel Blocks. Service Spanners. One spindle fitted with the Machine, bore dia capacity 64-135 mm.

Magnetic Core Drilling Machine

Get Price Quote

2 Unit (MOQ)

Drilling tool

Get Price Quote

DHD DEEP HOLE DRILLING

Get Price Quote

FEATURES Reinforced Core Design Superior Surface Treatment 4 Margins to Guide High Performance Coating Optimized Flute Design FUNCTIONS & BENEFITS Stable cutting edge Better Chip Evacuation Better Hole Straightness Superior Tool Life Eliminate Breakages RANGE 3mm to 16mm Available in 12X, 15X, 20X

Horizontal Floor Borer

Get Price Quote

Boring Machine

Get Price Quote

Description: Fixed Column, built-in Rotary Indexing Table which also travels transversally Wide range of spindle speeds & gearbox feeds allow for high output with the use of high-speed steel and carbide tools Hardened & ground alloy steel spindle Facing Head coupled with main spindle facilitates large diameter boring and facing operations Auto Rapid Travel for Facing Slide for improved productivity Independent motors for Spindle & Motor with Centralized Pendant Control for easy operation Telescopic Steel Covers for Guide ways to prevent ingress from damaging the guide ways Turcite B-Lining on all guide ways for smooth operation Machine is provided with Boring Bar and Support, Five Limit Switches Bigger main motor available, if required Bigger Rotary Table available, if required Accuracy: As per Grade-I limits of Dr. G. Schlesinger’s Acceptance Test Quality of bore attainable H-7 Ovality in bore: 0.01mm Position accuracy of Rotary Table: 0.02mm Application: Horizontal boring, drilling and surface milling Reaming, turning and facing using facing head slide Machining bores in gearboxes & machine bodies 30º taper boring for 100-300 mm diameter using Taper Boring Attachment Inch threading (5-128) and Metric threading (0.28-7.5) using Threading Attachment 360º vertical milling up to 600mm depth using Vertical Milling Attachment Accessories:Digital Read Out, Threading Attachment, Vertical Milling Attachment, Taper Boring Attachment

Core Drill Bit

Get Price Quote

Drilling Tools

Get Price Quote

we are recognized as one of the famous quality drilling tools manufacturers, suppliers and exporters from mumbai, india to all over the world. The collection of the down whole drill equipment obtainable by us includes rock augers, soil augers, bentonite augers, rock buckets, tapered buckets, excavating buckets, rotating flap buckets, cleaning buckets, core barrels, adapters and casing couplers to gather the particular supplies of the customers. The get-together tools are presented for the several of various types of soils of firm, rocky, average and high consistency. This instrument saves your time, money, and significantly reduces tools carry. Strong augers transport the concluding in long lasting reliability. Our equipments are practically consummate in quality. In addition, industrialized drillings are available in all categories and types according to price, size, structure and dimensions range from hole ø mm to 2500 mm. Drilling accessories also available, contact via phone, email or contact form if any doubt or queries. Best supporting staff available 24x7 for any kind of help and solve your queries instantly. drilling tools offered to all customers and clients with quality and safe equipment that will meet or exceed industry and government standards and practices. Experienced professional team are service oriented and available 24 hours a day. Our professionals are also working to make sure for 3d drilling tools would be pleased to full fill the client's requirement and service needs. drilling tools features precisely designed as per domestic weather simple, safe and secure in use