brake oil filling machine

Get Price Quote

Brake Fluid Plant FRIGMAIRES BRAKE FLUID MANUFACTURING PLANT PLANT CAPACITY 2000 LTRSDAY TOTAL POWER CONSUMPTION 15KW REQUIRED INSTALLED POWER 20 KW, 440 V 50 Hz, 3 Phase LABOR REQUIRED Skilled 2 Unskilled 2 with 1 Plant Chemist AREA 10X5X5 MTRS LXBXH. ADVANTAGES OF FRIGMAIRES PLANTS : Single Source responsibility for complete plant design right from Civil-Mechanical-Electrical to Chemical process. Client's scope of work limited to bare minimum. Know how and training based on years of manufacturing experience. Modern Laboratory set up to meet international specifications. Plant design complies with international standards and safety.

Filling Machine

250,000 - 300,000 Per Piece

Best Deals from Industrial Machine

Lubricant Filling Machine

Get Price Quote

Our auto grease filling machine has tin lifting arrangement which is provided for efficient grease lifting purposes. This auto grease filling machine is electro pneumatically operated and made by using excellent grade stainless steel and mild steel. It is known for its low electricity consumption as it requires only 415 V of alternating current. Our auto grease filling machine is widely demanded in packaging lines of different industries for providing smooth packaging operation and high accuracy. Furthermore, it is also equipped with volumetric filler and transfer conveyor.

Semi Auto Grease Filling Machine

Get Price Quote

This semi auto grease filling machine is widely demanded in different industries for filling of grease and gels into bottles, tins, pails or plastic cans. This semi auto grease filling machine is fabricated using supreme quality mild steel sheets and angles. It has all the contact parts like hopper are made by using stainless steel and high quality PTFE is used for wiper strips. The material flow through it is moved by rotating auger and the flow is controlled by using digital programmable timer. Furthermore, this semi auto grease filling machine is checked under various parameters to ensure its efficient and optimum working. Specifications: Material: industrial grease/gels etc Range: 0.5 to 5 kgs, in tins / pails / plastic cans Hopper Capacity: 35 ltr. approx. made out of 16 swg., S.S. 304 sheet Material flow: by rotating auger Flow control: digital programmable timer Fill setting: by thumb wheel switch Fill accuracy: - /+ 1 to 1.5 % or better At S.O.C. & S.O.P. Filling rate: 500 gms. / sec. or better Auger control: By E / M clutch break unit Drive transfer: using ‘V’ belt Auger drive motor: 1 H.P., 3 Phase, 415 V A.C. Mixer / wiper drive: using additional gear motor capacity 0.5 HP with suitable starter Power supply: 415 V A.C., 3 phase 4 wire Compress air supply: @ 6 kg / cm², cons 015 LPM. [not included] General construction: the machine fabricated out of M.S. angle, sheet etc, hopper and all other contact parts are made out of S.S. 304 and wiper strips of PTFE

Semi Automatic Punching Machine

Get Price Quote

Cylinder Drying Range Machine

Get Price Quote

Description Indirect drying using Stainless Steel Cylinders. Suitable for one or two sided drying of all types of fabrics. High Efficiency method for intermediate or final drying. Saliant Features Creaseless drying of fabric Minimum Maintenance Efficient steam consumption Consistently high quality standard Works with continuous processing ranges- Pre-Treatment, Mercerizing, Washing or Dyeing Stand Alone with/without Mangle Optional Accessories Teflon Coating on Drying Cylinders Moisture Controller System Temperature Controller System Steam Exhaust Hood Isolation of individual or group of Drying Cylinders By passing the Cylinder Dryer for wet to wet operation Restricting the stack entry of fabric to avoid over drying.

Cylinder Drying Range Machine

Get Price Quote

1.Indirect drying using Stainless Steel Cylinders. 2.Suitable for one or two sided drying of all types of fabrics. 3.High Efficiency method for intermediate or final drying.

Heat Shrink Tunnel Machine

35,000 Per Set

PP Cap Sealing Machine

Get Price Quote

PP cap sealing machine Foot operated Cap Sealing Machine are suitable for Capping ropp , screw and crown caps for all kind of Bottles. Working Table height is fixed. Bottle moves up and down by Pedal provided, gets sealed and comes down. Height of head is adjustable

automatic shrink wrapping machines

Get Price Quote

Shrink wrapping machines suitable for gift's confectionery, bottle, cosmetics etc. It's a high speed of sealing machine and high equipment sealing. The complete process is visible & is furnish with L- sealer shaped. The automatic process of shrinkable pouch complete with web- sealer. We are provide very high quality of heat-sealing machine and branded shrink machines. It's very easily used.

Heat Shrink Tunnel Machine

Get Price Quote

liquid filling machines

Get Price Quote

Manual Capsule Filling Machine

Get Price Quote

Features: Available in Full GMP and standard model. Very easy in operating and can easily be handled by any unskilled labour. Interchange ability:The machine is manufactured to suit 00, 01, 02, 03 or 04, 05 capsule size combinations

Foil Winding Machine

Get Price Quote

Foil Winding machine is fully customized to meet the requirements of special designs of dry type and oil cooled transformers. The integrated modular design allows various configurations with multiple foils insulation types coil shapes and material processing functions. This machine has a programmable control system with remote troubleshooting available integrated cold weld and tig weld system upto 2 foils of copper or aluminum. It also have servo of vector main drive system with automatic or manual run features.

Heavy Duty Industrial Paper Shredder Machine

Get Price Quote

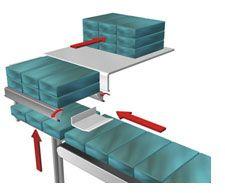

Vertical Collator / Matrix forming Shrink Wrap Machine

Get Price Quote

The vertical collation fully automatic shrink wrap machines are more suitable for Square, rectangular , specially its more suitable for boxes which have more face side contact to product travel conveyors and to collation plate. There will be two pushers ,one pushers pushes the products into upstairs with a proper guide and other pusher will push to web sealer 90 degree to product travel line. Pneumatic pusher collates the boxes / containers into the pre-selected pack formation, which upon completion is transferred forward into the welding position. At this stage the pack is clamped, the welding bar descents to complete the wrap or seal, and the pusher returns to prepare the next collation of product. As the welding bar ascends, the pusher advances to transfer the new collation into the welding position, at the same time displacing the previously wrapped collation onto continuously moving shrink tunnel conveyor. The wrapped collation soon enters the shrink tunnel chamber where re-circulated hot air causes the wrap to shrink and tightly conform to the contours of the contents. Once the pack is out of the hot chamber, forced air cooling is used to tighten sleeve wrap to achieve a strong, secure pack ready for stacking on pallet or a placing on a shipping carton.

Weighmetric Filling Machine

Get Price Quote

The Weighmetric Filling Machine is suitable for filling granules, free flowing powders, rice, pulses, nuts etc., on weight basis. Weight is controlled by a Load Cell with microprocess programmable system and has a high level of accuracy with the facility of course feed and fine feed. Filling ranges from 25 gms to 1 kg. Models for higher capacity upto 10 kgs. are also available. The feeding system is with electromagnetic vibrator. Optional equipments like a Automatic Screw Feed with level sensor and special models with multiple filling heads for higher output also available. Output upto 600 fillshr with an accuracy upto ± 1% for fill quantities over 50 gms or ± 2% for fill quantities upto 50 gms.

Bottle Filling Machine

135,000 Per Piece

notebook making machine

Get Price Quote

damping roller cloth, used offset printing machine, Uv Machine

Semi Automatic Spray Coating Machine

Get Price Quote

We offer minicota (semi automatic spray coating machine ) is mainly designed to replace the conventional method of manual coating of tablets and granules. mini cota is comprised of pressure vessel whish can be provided with s.s. Jacket (for sugar coating) with controlled heaters, sagety valve, pneumatic stirrer (oscillating type) , spraying nozzles and compact control panel with pneumatic cylinder for intermittent spray with timer.

lpg cylinder filling machine

Get Price Quote

Rapid Prototype Machine

80,000 Per Unit

1 Unit (MOQ)

bright bar machines

Get Price Quote

The Bright Bar Division manufactures a wide range of bright bars, specialising in stainless steel, through different processes like heat treatment, quenching and tempering, pickling, cold drawing, peeling, smooth turning, centreless grinding and polishing.

notebook making machine

Get Price Quote

Paper Bag Making Machines, Thread Book Sewing Machine

Rotary Wood Carving Machine

525,000 Per UNIT

cosmetic product machinery

Get Price Quote

cosmetic product machinery, Other Process Equipment

Socket

Get Price Quote

Socket, Black Power Socket, Led Street Lights, LED Panel Lights

Ancillary Equipment

Get Price Quote

Ancillary Equipment, Research Equipment

Industrial Machinery

Get Price Quote

Industrial Machinery, Woodworking Machinery, Electric Tools

Filling Machine

Get Price Quote

paint machinery, Pharmaceutical Machinery, Resin Plant, soap machinery