Industrial Credit Card Shredding Machine

Get Price Quote

Automatic Liquid Filling Machine

Get Price Quote

Best Deals from Industrial Machine

Automatic Pan Feeding System For Broiler

Get Price Quote

Automatic Tube Filling machine

Get Price Quote

Induction Cap Sealing Machine

Get Price Quote

Induction Cap-Sealing Machine ,available in compact sizes and minimizes the amount of free conveyor required to only 1.2m. The machine is provided with generator and special tunnel type head for high speed sealing mounted on a mobile frame with an internal water circulator ensuring superior functionality of the machine.

Semi Automatic Filling Machine

Get Price Quote

Our organization is a famed one that is located in Mumbai(India) and has a well-developed network for reaching different Mumbai(India)s. With our years of experience and expertise, we strive to make available high quality Semi Automatic Filling Machine at competitively low prices

Poultry Feeding Machine

98,000 Per Piece

Industrial Sewing Machines for Jute Carry Bags

Get Price Quote

Leveraging the skills of our qualified team of professionals, we are instrumental in offering a wide range of Elastic Attaching Sewing Machine. Offered Chain Stitch Elastic Attaching Sewing Machine requires less maintenance.Features: Superior performance Unmatched quality Anti-abrasive Applications: Used for stitching and embroidery purpose in number of fabric industries

shrink labeling machine

Get Price Quote

Shrink wrapping machine Consist of Special Stainless Steel Finned tubular heater for Lowest power consumption & Highest heat transfers. Temperature is Controlled with the help of Digital Temperature for Accurate amount of heat. Best Quality Shrink wrapping is obtained with the help of heavy duty blower which provides sufficient amount of heat transfer. Shrink wrapping machines comes with the world class insulating material like calcium silicate or asbestos sheets on the machine panel. The Conveyor rods of the shrink wrapping machine which passes from the hot shrink tunnel is coated with Silicon Tubes.

single head ropp capping machine

45,000 Per Piece

1 Piece(s) (MOQ)

Abucks inc offer ropp [roll on pilfer proof ] and plastic caps screw capping machine this is a moterised capping machine, this machine is used to seal caps made of plastic and aluminium metal easily applicable in plastic,glass,and metal bottles. This type of capping is mostly used in pharmaceutical and chemical industry for packaging liquids and syrup. The sealing of caps is done by the set of two rollers which rotates and forms a ring and seals the lower ring of the cap on the bottle while other creates the thread that enables easy removal and closure of caps.abucks inc ropp capping machine is motorized model which is provided with foot pedal switch. Bottles height from 40mm to 300mm can be capped with this ropp capping machine.

Automatic Shrink Wrapping Machine

600,000 - 720,000 Per Bag

Manual Capsule Filling Machine

Get Price Quote

Features: Available in Full GMP and standard model. Very easy in operating and can easily be handled by any unskilled labour. Interchange ability:The machine is manufactured to suit 00, 01, 02, 03 or 04, 05 capsule size combinations

Weighmetric Filling Machine

Get Price Quote

The Weighmetric Filling Machine is suitable for filling granules, free flowing powders, rice, pulses, nuts etc., on weight basis. Weight is controlled by a Load Cell with microprocess programmable system and has a high level of accuracy with the facility of course feed and fine feed. Filling ranges from 25 gms to 1 kg. Models for higher capacity upto 10 kgs. are also available. The feeding system is with electromagnetic vibrator. Optional equipments like a Automatic Screw Feed with level sensor and special models with multiple filling heads for higher output also available. Output upto 600 fillshr with an accuracy upto ± 1% for fill quantities over 50 gms or ± 2% for fill quantities upto 50 gms.

Shrink Wrapping Machines - Amar Packaging

55,000 - 200,000 Per each

1 per (MOQ)

bright bar machines

Get Price Quote

The Bright Bar Division manufactures a wide range of bright bars, specialising in stainless steel, through different processes like heat treatment, quenching and tempering, pickling, cold drawing, peeling, smooth turning, centreless grinding and polishing.

Plstic Tube Filling Sealing Machine

Get Price Quote

Volumetric Filling Machine

Get Price Quote

Features Optimum performance User friendly operation Easy maintenance Specifications Non contact electronic sensor to ensure "no bottle no fill" system Mitsubishi make PLC system with T" Touch screen and VFD control for conveyor speed control German measuring chamber for better repeatability of 0.05% Body frame made up of M.S with Powder coating or Stainless steel

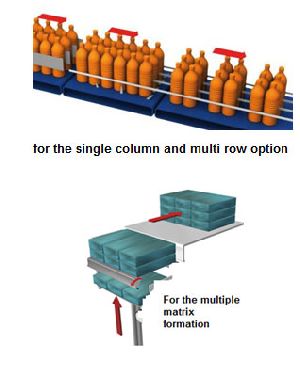

Straight feeding Shrink Wrap Machine

Get Price Quote

In a Straight feeding Shrink Wrap Machine The products which are planning to shrinkwrap will travel in a single line , inline to sealing unit and the products will collate on collation plate and pneumatic pusher which pushes the products onto sealing units (web sealer) but such option is possible only for the single column and with multiple row option i.e 1x1,1x2, 1x3,..1xn If you have multiple columns and rows then need an vertical pusher i.e for the matrixes 4x4, 3x4, 5x4 …nxn. Accordingly the machine size and pusher size infect all change parts will very and the packing time also In a single column and multiple row options a pneumatic pusher collates the boxes / containers into the pre-selected pack formation plate, which upon completion is transferred forwarded into the welding position. In and multiple row and column option there will two or multiple pusher to collate and form the matrix Once the required matrix gets formed by respective pushers as per set product size the pusher advances to push the formed matrix to sealing unit , once the matrix reaches the forming unit or forming plate the sensor gives the signal to welding bar accordingly it descents to complete the wrap, and the pusher returns to prepare the next collation of product. As the welding bar ascends, the pusher advances to transfer the new collation into the welding position, at the same time displacing the previously wrapped collation onto continuously moving shrink tunnel conveyor. The wrapped collation soon enters the shrink tunnel chamber where re-circulated hot air causes the wrap to shrink and tightly conform to the contours of the contents. Once the pack is out of the hot chamber, forced air cooling is used to tighten sleeve wrap to achieve a strong, secure pack ready for stacking on pallet or a placing on a shipping carton.

auto grease filling machine

Get Price Quote

Our auto grease filling machine has tin lifting arrangement which is provided for efficient grease lifting purposes. This auto grease filling machine is electro pneumatically operated and made by using excellent grade stainless steel and mild steel. It is known for its low electricity consumption as it requires only 415 V of alternating current. Our auto grease filling machine is widely demanded in packaging lines of different industries for providing smooth packaging operation and high accuracy. Furthermore, it is also equipped with volumetric filler and transfer conveyor. Specifications Packing range: 200 gm to 5 Kg. Capacity 34-36 Cans / Min. for 200 gm 20-24 Cans / Min. for 1 Kg 12-14 Cans / Min. for 2 Kg 8-10 Cans / Min. for 3 Kg 4-6 Cans / Min. for 5 Kg Filling accuracy: ± 0.5% of HPS At S. O. P. and S. O. C. Operation: electro-pneumatic Electric supply: 415 V AC, 3 Phase Power consumption: 5.5 HP Approx Air supply: @ 6 kg/cm2 Air Consumption: 120 LPM Man Power reqd: 2 Nos Space requirement: 6.1 Mtr. x 1.5 Mtr. IN-Feed Conveyor: Construction: dodge type Track width: 250 mm Height: 800 mm Length: 1000 mm + 2100 mm (in-feed + filler Guide rails: Adjustable Drive: HP gear motor Operation: electrical, through V/F drive Volumetric Filler: Filler: augur type volumetric type timer base [as per attached specs.] Range: 500 gm to 5 Kg Can lift auto infeed: pneumatic for cavity killing System: using infeed valve actuator assy. (40 mm) photo sensor operated Transfer conveyor (for lid dispenser & presser): Construction: S.S. slat belt type Belt width: 190 mm Track width: 250 mm Height: 800 mm Length: 3000 mm Linear Speed: 14 mtrs per min Guide Rails: adjustable Drive: ½ HP gear motor Operation: electric Technical Specification (Filler Unit): Material: industrial grease - temperature: 70-80 degree centigrade Range: 0.5 to 5 kg., in tins / pails Hopper capacity: 35 Ltr. approx. made out of 16 swg., S.S. 304 sheet Product feed: automatic through actuated valve having auto level control Material flow: by rotating auger Flow control: digital programmable timer Fill setting: with key pad switches Fill accuracy: ± 0.5% of HPS at S.O.P. & S.O.C. Filling rate: 300 gms. / sec Augur control - by E / M clutch break unit Drive transfer: using ‘V’ belt Augur drive motor: 1 H.P., 3 phase, 415 V A.C. Mixer / wiper drive: using additional gear motor cap. 0.5 HP with suitable starter Power supply: 415 V A.C., 3 phase 4 wire 230 V A.C., 1 phase 3 wire Compress air supply: @ 6 kg / cm² Consumption: 40 LPM General construction: the machine fabricated out of M.S. angle, sheet etc, hopper and all other contact parts are made out of S.S. 304 and wiper strips of PTFE

brake fluid filling machine

Get Price Quote

Single Source responsibility for complete plant design right from Civil-Mechanical-Electrical to Chemical process. Client's scope of work limited to bare minimum. Know how and training based on years of manufacturing experience. Modern Laboratory set up to meet international specifications. Plant design complies with international standards and safety features. Automotive brake fluid has many responsibilities. Corrosion protection and lubrication of brake system components are only a portion of the role brake fluid must play. All automobiles that have a hydraulic braking system must use brake fluid in order for the brake system to operate. The type of fluid used can depend on the type of vehicle and the demands of the vehicles brake system. The two most common brake fluids used in the automotive industry are fluids that contain Polyalkylene Glycol Ether and fluid that contains Silicone or Silicium-based Polymer. Both Fluids are common but very different in regards to the manner in which they perform. Fluids containing Polyalklene Glycol Ether are more widely used and are the only fluids that should be used in racing brake systems. Because brake systems may reach extreme temperatures brake fluid must have the ability to withstand these temperatures and not degrade rapidly.

Oil Filling Machine

38,000 Per Piece

Bottle Filling Machine

135,000 Per Piece

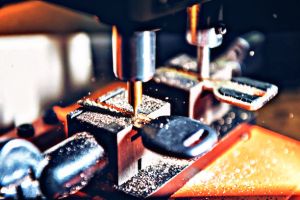

computerised key making machine

Get Price Quote

Feeder Management Relay Machine

Get Price Quote

brake fluid filling machine

Get Price Quote

FRIGMAIRES BRAKE FLUID MANUFACTURING PLANT PLANT CAPACITY 2000 LTRSDAY TOTAL POWER CONSUMPTION 15KW REQUIRED INSTALLED POWER 20 KW, 440 V 50 Hz, 3 Phase LABOR REQUIRED Skilled 2 Unskilled 2 with 1 Plant Chemist AREA 10X5X5 MTRS LXBXH. ADVANTAGES OF FRIGMAIRES PLANTS : Single Source responsibility for complete plant design right from Civil-Mechanical-Electrical to Chemical process. Client's scope of work limited to bare minimum. Know how and training based on years of manufacturing experience. Modern Laboratory set up to meet international specifications. Plant design complies with international standards and safety.

lpg cylinder filling machine

Get Price Quote

Industrial Cloth Dryer Machine

Get Price Quote

With a front loading design, robust construction. It has a distinctive appearance. Inside basket is made of stainless steel. Steam / electric or its combination, or thermic fluid heating is offered. Capacities varies from 6kg. to 100kg. Auto reverse & auto stop by digital timer.

Battery Sealing Machine

Get Price Quote

It is suitable for circumstances where the size of the cartons does not change frequently, which especially fits for continuous sealing of cartons in the same size. The machine is used in the fields of the domestic electrical appliances, foodstuffs, general merchandise, medicine & chemical industries.

Powder Filling Machine

160,000 Per Piece

Rapid Prototype Machine

100,000 Per Unit

1 Unit (MOQ)