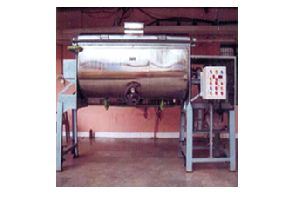

Sigma Mixer

Get Price Quote

Sigma Mixers (Kneader) is modern heavy duty mixer specially designed to produce uniform mixing and kneading heavier viscosity materials.

Sigma Mixers

Get Price Quote

Sigma Mixers are the hi-tech machines used for kneading and uniform mixing of materials with heavier viscosity. We are regarded as one of the prime Manufacturers and Installers of Sigma Blade Mixers in India. We manufacture two types of sigma mixers Single Sigma Mixers and Double Sigma Mixers. The sigma mixers manufactured by us are widely used in the making of rubber compounds, flush colors, adhesives, soap, food dough, stiff pastes, brake lining compounds, PVC coatings, etc. These sigma mixers are invested with various salient features that add to their efficiency like Heavy duty gears Grills to provide maximum security Shaft sealing by Teflon Chevron Rings to prevent leaking. Mild steel fabricator Specialized blades designed to mix the materials thoroughly. We pay special attention to the installation of the sigma mixers and provide our customers with after sales service. Operation Loading of material is done through top of mixer on opening the lid or through the feeding mouth / hopper. On starting the machine, the tangential action of mixing and kneading is thoroughly obtained by √ĘÄėZ√ĘÄô shaped kneading blades, which rotates very accurately at different speed towards each other causing product to be transferred from blade to blade. Discharge of the mixed product is achieved by tilting the container or through the valves at the bottom or by means of an extrusion screw below the container if provided. Salient Features Sigma Mixer (Kneader) is a Batch Mixer Mixing Trough and Blades are fabricated from mild steel / various grades of stainless steel. Product contacting parts are ground, buffed or smooth and clean working. Blades are designed to obtain thorough mixing of high viscosity materials. Blades are machined on a leading edge to keep minimum equal gap between through walls and blades. Heavy-duty gears are fitted to the blades. Shaft sealing into the stuffing boxes is provided by Teflon Chevron Rings / PTFE breaded gland rope to prevent leaking from blade ends. Guards / Grills and interlocking are provided for maximum safety. Options GMP / Non GMP / models. Discharge by tilting container / bottom sliding valves / bottom gates / flush bottom gate valves. Tilting by hand liver / hand wheel with lead screw / electrical arrangements / hydraulic systems. Lifting of lead either manually, with help of counter weights or hydraulically. 'Z' Type Spiral blade / Naben / double naben blades to circulate hot / cold water in cases of heavy masses. Jacketed shell for heating or cooling by steam, oil, water etc. with fiber glass insulation over the jacket. Working facility with vacuum or pressure. Spray system for liquid addition / gas purge. Flame proof / Non-flame proof electrical controls. Wireless remote control operation for toxic materials. Electric (FLP/Non FLP) / Hydraulic drives.

Best Deals from Industrial Mixers

Paddle Mixer

Get Price Quote

RaviKiran are Manufacturers of Paddle Mixer, ideally suitable for mixing of wet mass, dry powder, dry powder with wet mass, etc, for the preparation of pharmaceutical mass for preparing tablets and similar other applications. The mass mixer gives through mixing due to its unique blade design and the angle of the blade. Granulation Line:- Mass Mixer and Ribbon Mixere ideally suitable for mixing of wet mass, dry powders with wet mass, etc. for the preparation of pharmaceutical mass for the preparations of tablets.

Mass Ribbon Mixer

Get Price Quote

The Mass Mixer is ideally suitable for mixing of wet mass, dry powders with wet mass, etc. for the preparation of pharmaceutical mass for the preparations of tablets.   Salient Features: The trough design is such as to evenly distribute the material throughout. The unique blade design and placement facilitate in the mass moving completely from top to bottom and laterally from one end to the other without operator interference. The open top design is suitable for addition of material while in operation and also for visual inspection. The complete trough can be tilted for unloading of the material. RaviKiran are Manufacturers of Paddle Mixer, ideally suitable for mixing of wet mass, dry powder, dry powder with wet mass, etc, for the preparation of pharmaceutical mass for preparing tablets and similar other applications. The mass mixer gives through mixing due to its unique blade design and the angle of the blade. Granulation Line:- Mass Mixer and Ribbon Mixere ideally suitable for mixing of wet mass, dry powders with wet mass, etc. for the preparation of pharmaceutical mass for the preparations of tablets. Description: The mixer is provided with a U shaped trough with a centrally mounted shaft passing laterally through the trough. The shaft is provided with a set of blades welded at different angles each blades has a dedicated mixing function. The angle of the blades is such that through, efficient and complete mixing of the material takes place. The material due to the unique blade design is subjected to lateral as well as vertical motion and the complete material is rolled inside out and for bottom to top, due to which complete mixing takes place and a homogenous mass is obtained. The control shaft is provided with gland packing at both ends for complete sealing. The central shaft is coupled to a suitable gear box and a suitably powered motor. The complete assembly is mounted an bearing blacks bolted to the frame of the machine. The machine is provided with a manual tilting mechanism of the side with gear mechanism for unloading the material into the collecting tray (motorized tilting for higher capacity models available as an option). The trough can be tilted in the front up to 90 Degrees by rotating the handle provided at the side. The mixer is provided with a sliding and open able top cover with safety guard so that the operator does not accidentally put the hand inside the trough when the machine is in operation. The top cover is provided with a limit switch to stop the machine as soon as the top cover is opened. Salient Features: The trough design in such as to evenly distribute the material throughout. The unique blade designs and placements facilitate in the mass moving completely from top to bottom and laterally from one end to the other without operator interference. The open top design is such that addition of material while in operation and visual inspection is possible. Limit switch provided for the top cover to stop the machine when the cover is lifted.

pvc high speed mixer

Get Price Quote

Inner part of the vessel is made from SS 304 and outer part is made from graded mild steel. It is equipped with temperature sensor and provided with water circulation system for cooling. The container is designed specially to remove moisture by means of generating sufficient heat due to friction. Thus resulting into free flowing dry mixing.

Mixing Machine For Gypsum MRC

Get Price Quote

The most delicate operation in the various stages of melting lost wax consists of the preparation of the cylinders of refractory plaster. The machine performs the mixing operations of the gypsum and filling of the vacuum cylinder in a very short time. This allows, during the compaction of the gypsum, to obtain a non-wrinkled surface, reducing the time for pre-finishing and especially the loss of metal. FEATURES: ‚ÄĘ Motor of the two-speed mixer, for mixing and rinsing; transmission belt and toothed pulleys. ‚ÄĘ Bell in stainless steel, with transparent floor in Plexiglas. ‚ÄĘ The machine and 'built in such a way as to allow the use of different heights bells. ‚ÄĘ electromagnetic vibrator with potentiometer for varying the intensity of the vibrations ¬† ¬†

cage blender

Get Price Quote

The cage blenders tumble the in process containers as the preferred method for quick & efficient blending, reducing the number of product exposures point in the process, the material handling & cleaning requirements. Gentle tumbling motion reduces fines creation. Fitted with lid, butterfly & split butterfly valves for dust free loading & discharge.

1000 L Stainless Steel Liquid Mixing Tank

250,000 Per Piece

1 Piece (MOQ)

direct drive mixer

18,000 - 45,000 Per Piece

1 Piece (MOQ)

Direct Drive Mixer used for low viscosity fluids like in water treatment plant, chemical plant, and dairy plants. They are available in three basic speeds, 1400 rpm, 960 rpm, 750 rpm and power ranging from 0.18 kw to 2.2 kw. Flange and angular bracket mounting position is available. Lifting lowering stand suitable for different tank sizes is an optional accessory to Cyclone direct drive mixers. Different mixing impellers like propellers, pitched turbines and other axial or radial flow turbines can be fitted for different properties of fluids and applications.

conical mixer

Get Price Quote

Double Cone Blender

Get Price Quote

Manufactured using high-grade basic material and advanced techniques, our Double Cone Blender is high in demand in the market. Tested using the latest techniques, our Double Cone Blender is free from all kinds of defects. We are an experienced name, which is engaged in manufacturing and supplying Double Cone Blender. One can place retail as well as bulk orders for Double Cone Blender with us. Highlights : Efficient & versatile mixer Ideal for mixing powders & homogenous lubrication of granules M.O.C.: S.S 304 / 316 / 3161 5.5. Baffles are provided Safety guards provided with limit switch interlocked to motor Capacity 20 ltrs. To 5000 liters Automatic loading & unloading facilities available (option) CGMP model with documentation (IQ, DQ, PQ, 0Q) as option

blunger machine

Get Price Quote

Drum Blending Machine

Get Price Quote

Mass Mixer

Get Price Quote

¬† General Specification: Shell :¬†Consisting of ‚ÄėU‚Äô trough of suitable dimensions. Construction of ¬†S.S and side plates duly M.S stiffened from outside and from inside with S.S. Mixing Mechanism :¬†Paddle type blades welded to the main shaft provide for efficient mixing of thick heavy material. PTFE gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage. Charging :¬†From the top charging can be done through hingeable lid, Hopper or Nozzle can be provided for additional spraying of additives. Discharge :¬†By bottom discharge slide Iris or Butterfly valve of suitable diameter, for regulated discharge. Drive :¬†Consisting of suitable HP TEFC 3 phase ac 415v / 50 cycles motor ¬†coupled to suitable worm gear, with driving shafts mounted on suitable plummer block. Mounting :¬†Mounted on suitable ISMC Section Stand, with protective covers for belts and couplings. MOC :¬†All contact parts in S.S construction. Complete unit with S.S. cover and all surfaces polished to mirror dull finish. MS parts dull painted to smooth finish. ¬† Options Available :¬†¬†The control panel is mounted on platform and is provided. ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬†¬†¬†1. ¬† ¬†¬†¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬† ¬†

High Shear Mixer

Get Price Quote

Rufouz Hitek Engineers design such range of Static Mixer which are well efficient in lowering the energy cost of your plant. Our new advanced mixer ensures constant operation. They also posses extra control options for manual and automatic operation. Our mixer is equipped with metal or plastic pipe with best internal elements. All these features help in saving the usage of chemicals into the process. Static mixer design works on a simple but effective technique. The main principle of Static mixer is uniformity in the flow to increase the life time of the device. We are counted as the front player manufacturers of static mixer in India. We supply numerous types of static mixer which are made up of excellent raw materials. We possess with huge number of clients in worldwide locations due to our excellent designs and this helps us in becoming the leading static mixers suppliers. We are also known for manufacturing the finest range of inline static mixer.

Offset Ink Mixing Machine

Get Price Quote

1 Piece (MOQ)

INK Mixing Machine. All fabrication body MS material With SS material vessel (5kg to 100 kg), Gear Box & Branded Motor and VFD Speed Controller.

Mass Mixer

Get Price Quote

The Mixer consists of mixing drum complete in itself. It contains a mixing drum body, mixing paddle and sealing arrangement. The drum rests on rigid M.S. fabricated body carrying motor, gear box, starter and tilting arrangement. The drive of mixing paddle is through suitable oil filled worm gear unit which in turn gets drive through V belts from a suitable T.E.F.C. motor. The blades of the paddle are so arranged that thorough mixing is obtained. All parts which are in direct contact with the material to be mixed are of S.S. or neutral material. The main paddle runs in journals and supported by thrust bearings of ample size to carry rigid and thrust load. The whole drum of the mixer makes for ease of cleaning. The rotor is so designed that it can be removed by removing the main shaft without much problem. ADDITIONAL FEATURES: • Plastic Dust Cover provided to see the process all the times. • Safety : If motor covers open it will trop off automatically. • Tilting Device is provided to ease the unloading of the material Specially designed self-adjusting sealing arrangement Provision is made for lubricating all moving parts

digester mixer

Get Price Quote

The Conventional Mixing System installed in Digester invariably has a lot of issued related to inadequateimproper mixing , dead zones and settlement of heavy deposits in the Digester. This results in very poor efficiency of the Digester.

BrINE Agitators

Get Price Quote

We manufacturer two different models of Brine Agitator. MONO BLOCK / COUPLED BRINE AGITATOR Made up of heavy duty M.S. Pipe in which a 1½” (38 mm.) shaft is fitted with gunmetal bush at both ends or taper rolling / ball bearing as required by the customer. These agitators are fitted with 14” Dia. C.I. Impeller/ Fan and the capacity of the agitator can be varied by changing the degree of Impeller/ Fan blades. V BELT DRIVEN BRINE AGITATOR Made up of heavy duty M.S. Pipe in which a 2" (50 mm.) Shaft is fitted. The shafts has gunmetal bush at the fan end and taper roller bearing at the pulley end and are fitted with various sizes of C.I. fan / impeller. i.e. 8”, 12”, 16”, 18” & 20” according to capacity of the ice plant. These agitators come in different models suitable for various depths of tank or as per customer requirement.

Ribbon Blender Mixer

Get Price Quote

The Ribbon Blender does homogenous mixing of powder and granules of different densities. The Blender consists of a Semi-cylindrical shell inside which rotates a shaft welded with spiral inner and outer ribbons. The outer ribbon blades pushes the material at the centre of the container and simultaneously the inner ribbon blades pushes the material at the either ends of the container. Ribbon Blenders comprises of curved horizontal ribbon  blades that provides easy operation which are mostly used by Chemicals, Plastic, Pharmaceutical, Paints and Food industries. The ribbon blades of different designs are used to suit the need of different materials.  Ribbon Blenders are fabricated in capacities ranging from 50 liters to 5000 liters  with material of construction SS 316/SS316L Mixing is achieved in 15 to 20 minutes.

Industrial Stirrer

22,000 Per Piece

We are offering stirrer for mixing liquid, powder etc. availabe in 2 type 1. Single jacket 2. Double jacket 1. Single jacket - available in 2 hp, 3 hp and 5 hp. capacity - 250 ltr, 300 ltr, 400ltr, 2. Double jacket with gear box - 10 hp, 15 hp & 25 hp.

investment mixing machine

175,000 Per Piece

Features: The Best quality of embedding in investment & flask. High quality of casting at lower cost of production. ST 5F mixture, stand-alone type design to fill 5 flasks under vacuum. (Dia. 110 x H 200) Simultaneously it laid out mix 7 Kg of embedding material in vaccum. Now it is possible to produce even a small number of casting in excellent quality with respect to the surface quality & the counter sharpness. All machine parts are made of special steel & Aluminium, therefore there will be little maintenance & reduced wear (affected by Gypsum & Water) On demand it possible to provide variable adjustment revolution speed with respect to the Corresponding embedding procedure.

Titanium Agitator Tank

Get Price Quote

We have carved a niche in the market as the Manufacturer & Supplier of Titanium Agitator Tank based in Maharashtra, India. We make use of high-grade materials and the latest machinery for fabricating the Titanium Tank in compliance to set industrial standards. To ensure customer satisfaction, we pass the Titanium Tank through stringent quality checks before the final delivery. We are offering Titanium Agitator Tank at nominal rates. For More Information Please Visit On : WWW.SAITITANIUM.IN

Order Inline Mixer

Get Price Quote

Inline Mixer manufactured by Rufouz Hitek Engineers serve in all major industries related to the engineering fields. They are extensively used to smooth the progress of heat as well as mass transfer. The technique of gashing and reunification helps this device to becoming a great mixing equipment. They are able to ensure complete interruption free process. In such mixer fluids flow rapidly either from clockwise or anticlockwise direction to give consistency in product quality.

Conta Blender

Get Price Quote

V Blender

Get Price Quote

‚ÄĘ Model Available : 15 Litres to 1500 Litres. ‚ÄĘ M.O.C.S.S 304 / 316 / 316L ‚ÄĘ The Blend is Achieved by the Constant Dividing & Intermeshing of particle movement provided by two Connected Cylinders. ‚ÄĘ The Particle size reduction is Minimized Due to the absence of any moving blades. ‚ÄĘ Suitable for Quick & Efficient mixing for a complete range of Powders, Particulate & Granular Materials. ‚ÄĘ Easy Charging of Materials through S.S. Bins. ‚ÄĘ Safety guards provided with limit switch interlocked to Motor. ‚ÄĘ Option Flame Proof Motor & Control Panel. Mechanical / Hydraulic Pallet Truck. Variable Frequency Drive (VFD). Material Charging Platform. Can be offered for Vacuum Application. ‚ÄĘ GMP model with Documentation (IQ,DQ,PQ,OQ). ¬†

Double Cone Blender

Get Price Quote

The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. Salient Features - The conical shape at both ends enables uniform mixing and easy discharge. - The cone is statically balanced to avoid any excessive load on the gear box and motor. - While the power can be loaded into the cone through a wider opening, it can be discharged ¬†¬†¬†through a butterfly or slide valve. - Depending upon the characteristic of the product, paddle type baffles can be provided on ¬†¬†¬†the shaft for better mixing. - The contact parts are made of either S.S.304 or S.S.316. - Flame proof electricals can be provided as optional. - Capacity available 20 L to 3000 L. - The working capacity can be exchanged to 70 % of gross capacity by validated study. - ‚ÄėSlant‚Äô designed (off centre) CLIN CONE BLENDER is also available. - Variable speed option available 70 %. - Cantilever model on request. - Dust free bin charging system on request. Applications - Dry powder to powder mixing for tablets and capsules formulations. - Dry granules sub lots mixing to increase the batch size at bulk lubrication stage of tablet ¬†¬†¬†granules. Capacity : 10 Ltrs. to 5000 Ltrs.

magnetic mixer

Get Price Quote

TECHNICAL SPECIFICATION :   Complete vessel design as per ASME Code. Instrumentation & connections comply with BPE & EHEDG guideline. Vessel design & fittings / Stirrer are designed for CIP / SIP able.   OPERATION :   Complete aseptic design with Magnetic mixer & high shear Magnetic emulsifier. Zero dead leg aseptic design Flush bottom outlet diaphragm valve with SIP able. Sampling valve zero dead leg type with CIP/SIP able. Volume monitoring by Load Cell. PH Sensor / Conductivity Sensor provided on demand for online check Product PH & Conductivity.   ADVANTAGES :   Free and clean working area around the charging port. Variable speed drive allows to control of mixing speed while batch preparation. Designed in accordance with cGMP requirements for CIP and SIP. Mixing head designed for vigorous mixing or low volume blending. Magnetically powered drive, NO SEALS / NO SHAFT thereby eliminating contamination. Easy removable of drive unit.

Ribbon Blender

Get Price Quote