investment mixing machine

175,000 Per Piece

Features: The Best quality of embedding in investment & flask. High quality of casting at lower cost of production. ST 5F mixture, stand-alone type design to fill 5 flasks under vacuum. (Dia. 110 x H 200) Simultaneously it laid out mix 7 Kg of embedding material in vaccum. Now it is possible to produce even a small number of casting in excellent quality with respect to the surface quality & the counter sharpness. All machine parts are made of special steel & Aluminium, therefore there will be little maintenance & reduced wear (affected by Gypsum & Water) On demand it possible to provide variable adjustment revolution speed with respect to the Corresponding embedding procedure.

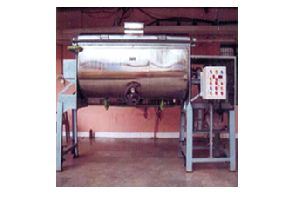

Ribbon Blender

Get Price Quote

Ideal for Uniform & Homogeneous mixing of dry / semi wet blending & mixing of various materials having different densities provided with various designs of the blades to suit the process requirement. The automatically / manually operated. Used in Pharmaceuticals, Chemical, cosmetics, Foods industry.Capacity ranges – From 10 Liters to 25000 Liters.M.O:- Can be manufactured in all weld able materials, CS, SS, & Special Steel.

Best Deals from Industrial Mixers

Sigma Mixer

Get Price Quote

stock blender

Get Price Quote

Industrial Mixers

Get Price Quote

The offered Industrial Mixers is manufactured using optimum quality components and cutting edge technology. In order to maintain the quality, our quality experts test this Industrial Mixers on different parameters. Owing to their easy to operate feature and low maintenance requirements, these Mixers are highly demanded. This Mixers is inspected on diverse parameters of quality in order to assure its flawlessness.

V Blender

Get Price Quote

Ribbon Blender

Get Price Quote

direct drive mixer

18,000 - 45,000 Per Piece

1 Piece (MOQ)

Direct Drive Mixer used for low viscosity fluids like in water treatment plant, chemical plant, and dairy plants. They are available in three basic speeds, 1400 rpm, 960 rpm, 750 rpm and power ranging from 0.18 kw to 2.2 kw. Flange and angular bracket mounting position is available. Lifting lowering stand suitable for different tank sizes is an optional accessory to Cyclone direct drive mixers. Different mixing impellers like propellers, pitched turbines and other axial or radial flow turbines can be fitted for different properties of fluids and applications.

1000 L Stainless Steel Liquid Mixing Tank

250,000 Per Piece

1 Piece (MOQ)

inline mixers

Get Price Quote

Inline Mixer manufactured by Rufouz Hitek Engineers serve in all major industries related to the engineering fields. They are extensively used to smooth the progress of heat as well as mass transfer. The technique of gashing and reunification helps this device to becoming a great mixing equipment. They are able to ensure complete interruption free process. In such mixer fluids flow rapidly either from clockwise or anticlockwise direction to give consistency in product quality. All the internal parts are well attached so that internal pressure remains constant. We made such types of internal parts that aids in ideal mixing and increase the quality of the product by adding realistic results. According to the different needs of various clients, they come in a wide range, so try to choose that design which suits best to you. Inline mixers are applied in various applications to get the desired output. They are highly preferred for facilitating the process of reaction engineering, heat transfer and mass transfer. We offer the variety of ranges to meet different purposes with their own unique flow patterns. Along with this Rufouz Hitek Engineers Pvt. Ltd. also offer Static Inline Mixer designs to our clients. Degree of mixing required, ability to be cleaned, appropriateness of scale-up, pressure fall, shear rate, residence time allotment, heat transmission and hold-up volume are some essential factors that actually decided the efficiency of the inline mixers.

Conta Bin Blender

Get Price Quote

Ideal equipment for blending within a closed environment and dust free operation. The Quality of the blending is achieved by the shape of the container without any internal baffles. The unit is most suitable for handling of different size containers by using a common drive. Salient Features : 0° stopping for easy docking and undocking of the bin Safety guard around the blender bin Proximity Sensor is provided for safe operation Flexibility of accepting variable bin sizes in single drive unit. cGMP Construction S.S. 316 Butterfly valve at the bottom suitable for discharge. Vent nozzle on top Most effective for low volume active ingredient blending with as low as 1 to 1.5%

Double Cone Blender

Get Price Quote

It is composed of two truncated cones joined together by cylindrical section. A tight closing lid of the fast closing type for feeding material and a discharge butterfly valve at the other end of the unit which also renders a perfect tightness. "The working capacity of the Blender is 65% of total volume". The blender is recommended preferably when the product to be mixed having a similar density and particular size as well as no lumping properties. Baffles are provided in bigger unit for intense mixing. The blending time is around 10 to 20 minutes (approx) as a maximum. Models available from capacity 5Ltrs to 6000ltrs (Higher capacities on request)

Static Inline Mixer

Get Price Quote

We are one of the leading static inline mixer manufacturers, exporters, and suppliers in india. The static inline mixer, offered by us, has no moving parts and it utilizes the energy of the continuous flowing fluids itself. Our static inline mixer efficiently mixes solids, liquids, and gases in any combination. used for blendingdispersionheat exchangeemulsificationph controlflash mixingmass transferslurry suspensiongas-liquid contacting features of static inline mixer simple & compacthigh energy efficiencylow capital & operating costis used for continuous processhigh degree of operational safetyhave no moving parts and hence maintenance freehigh degree of mixing per unit of expended energysize can be selected to suit existing pipeline size available in all sizesdifferent end connections:flangedscrewedidf headsvarious materials:316 ss304 sscarbon steeltitaniummonelhastealloypolypropylenepolytetrafluroethylene [teflon]polyvinyl chloridefiberglass reinforced polyesterpp/frphigh density polyethylene

Drum Blending Machine

Get Price Quote

BrINE Agitators

Get Price Quote

We manufacturer two different models of Brine Agitator. MONO BLOCK / COUPLED BRINE AGITATOR Made up of heavy duty M.S. Pipe in which a 1½” (38 mm.) shaft is fitted with gunmetal bush at both ends or taper rolling / ball bearing as required by the customer. These agitators are fitted with 14” Dia. C.I. Impeller/ Fan and the capacity of the agitator can be varied by changing the degree of Impeller/ Fan blades. V BELT DRIVEN BRINE AGITATOR Made up of heavy duty M.S. Pipe in which a 2" (50 mm.) Shaft is fitted. The shafts has gunmetal bush at the fan end and taper roller bearing at the pulley end and are fitted with various sizes of C.I. fan / impeller. i.e. 8”, 12”, 16”, 18” & 20” according to capacity of the ice plant. These agitators come in different models suitable for various depths of tank or as per customer requirement.

Titanium Agitator Tank

Get Price Quote

We have carved a niche in the market as the Manufacturer & Supplier of Titanium Agitator Tank based in Maharashtra, India. We make use of high-grade materials and the latest machinery for fabricating the Titanium Tank in compliance to set industrial standards. To ensure customer satisfaction, we pass the Titanium Tank through stringent quality checks before the final delivery. We are offering Titanium Agitator Tank at nominal rates. For More Information Please Visit On : WWW.SAITITANIUM.IN

Industrial Stirrer

22,000 Per Piece

We are offering stirrer for mixing liquid, powder etc. availabe in 2 type 1. Single jacket 2. Double jacket 1. Single jacket - available in 2 hp, 3 hp and 5 hp. capacity - 250 ltr, 300 ltr, 400ltr, 2. Double jacket with gear box - 10 hp, 15 hp & 25 hp.

POP Mixing Machines

Get Price Quote

Offset Ink Mixing Machine

Get Price Quote

1 Piece (MOQ)

INK Mixing Machine. All fabrication body MS material With SS material vessel (5kg to 100 kg), Gear Box & Branded Motor and VFD Speed Controller.

Mass Mixer

Get Price Quote

The Mixer consists of mixing drum complete in itself. It contains a mixing drum body, mixing paddle and sealing arrangement. The drum rests on rigid M.S. fabricated body carrying motor, gear box, starter and tilting arrangement. The drive of mixing paddle is through suitable oil filled worm gear unit which in turn gets drive through V belts from a suitable T.E.F.C. motor. The blades of the paddle are so arranged that thorough mixing is obtained. All parts which are in direct contact with the material to be mixed are of S.S. or neutral material. The main paddle runs in journals and supported by thrust bearings of ample size to carry rigid and thrust load. The whole drum of the mixer makes for ease of cleaning. The rotor is so designed that it can be removed by removing the main shaft without much problem. ADDITIONAL FEATURES: • Plastic Dust Cover provided to see the process all the times. • Safety : If motor covers open it will trop off automatically. • Tilting Device is provided to ease the unloading of the material Specially designed self-adjusting sealing arrangement Provision is made for lubricating all moving parts

Static Mixer

Get Price Quote

Rufouz Hitek Engineers design such range of Static Mixer which are well efficient in lowering the energy cost of your plant.The main principle of Static mixer is uniformity in the flow to increase the life time of the device.Buy static mixer from hitekengineers with best cost.

Octagonal Cone Blender

Get Price Quote

The main drum of the Octagonal Blender is coupled to a suitable motor through an oil filled gear box mounted on a sturdy frame structure. The unit is provided with a butterfly valve at one side and is provided with removable baffles inside the drum. The other side is provided with amanhole for accessibility inside the chamber for cleaning. An electrical panel is provided for housing the motor on-off starter, timer, inching device etc. Granulation Line:- Octagonal Blender is coupled to a suitable motor through an oil filled gear box mounted on a sturdy frame structure. a butterfly valve at one side and is provided with removable baffles inside the drum. Salient Features: Due to its unique design lower power consumption at higher loads is possible. Large capacity models are possible due to its compact design. The inside of the blender is completely cleanable through the man hole provided at one side. Also the baffles are removable and can be easily removed for cleaning. Ease in loading through the loading container or through the over head silo or by vacuum transfer is possible. Due to its compact design, lesser floor space required compared t other blenders.

V Blender

Get Price Quote

V blender consists of two large diameter pipes cut to 80ºangle and welded together to form a V shaped body. Inlets are located on top of the body, outlet is at the bottom of V point where there is transition from an elliptical to cylindrical discharge port. Salient Features - Easy to clean. - Minimum maintenance. - The Bin charging system can also be incorporated in it which is a dust free closed system for charging and discharging of powders or granules. - Material of construction S.S 316 Applications - Dry powder to powder mixing for tablets and capsules formulations. - Dry granules sub lots mixing to increase the batch size at bulk lubrication stage of tablet granules. - Dry powder to wet mixing. Capacity : 10 Lto 5000 Ltrs.

High Speed Mixer

Get Price Quote

High Speed Mixer, Grinder, Blown Film Plant, hdpe pipe plant

pvc high speed mixer

Get Price Quote

Inner part of the vessel is made from SS 304 and outer part is made from graded mild steel. It is equipped with temperature sensor and provided with water circulation system for cooling. The container is designed specially to remove moisture by means of generating sufficient heat due to friction. Thus resulting into free flowing dry mixing.

High Speed Mixers

Get Price Quote

The machine is assembled around a center column and head including drive with dispersing blade is raised and lowered by motorized hydraulic system. Container fixing brackets are provided self centering with locking arrangements.

jet mixers

Get Price Quote

jet mixers, water separators, water in fuel oil emulsion, static mixers

cage blender

Get Price Quote

The cage blenders tumble the in process containers as the preferred method for quick & efficient blending, reducing the number of product exposures point in the process, the material handling & cleaning requirements. Gentle tumbling motion reduces fines creation. Fitted with lid, butterfly & split butterfly valves for dust free loading & discharge.