LED Pressure Die Casting Mould

Get Price Quote

We are a trusted name, engaged in offering LED Pressure Die Casting Mould to our clients. Under the stern vigilance of our diligent technocrats, the offered mould is manufactured using the supreme quality inputs and progressive technology. Available at the cost-effective prices, the offered die casting moulds are highly requested for their various attributes like corrosion resistance, high tensile strength, and durability. Our offered products are optimum in finish. These are acknowledged by the clients for their simple installation and long life.

Graphite Mould For Gold Ingots

900 - 2,000 Per No

1 no (MOQ)

We have skilled professionals at our firm for offering best Graphite Mould for Ingots. These presented products are superior in quality and available in the market in various sizes and shapes. Moreover to this, these presented products are best in finishing and easier to use. Features: Perfect finish Different sizes Reliable

Best Deals from Industrial Molds

Plastic Molds, Plastic Products

Get Price Quote

Plastic products development and production: apart from manufacturing plastic machineries we underta ke development and provide production of tailor made plastic blow (from 0.5 mls) & injection molded articles plastic molds: blow and injection moulds- developed as per your design drawings samples provided. dave technical services provide complete solutions for your plastic products requirement from design development to molds development, trail runs, product approvals, production of the same to option of supply of entire plant and machinery at the clients place for self manufacturing. we collaborate with our customers to provide tailor-made and value- added solutions for their application challenges. Variety of products are developed for various industries like pharmaceutical and medicals, chemicals, consumer packaging, disposables, toys, industrial packages and products, promotional products, bellows, households, appliances, agriculture, agrochemicals and many more customized developments

Cooling Pipes

Get Price Quote

Catering to the requirements of several industries, we put forward a variety of Cooling Pipes. We have association with reliable vendors in China to acquire the finest range of Cooling Pipes. The Cooling Pipes are made from high-quality materials. Thereby, Cooling Pipes last long as compared to the ordinary ones. Cooling Pipes can be availed in different specifications from us. We are a well-known Cooling Pipes Importer and Supplier in Maharashtra (India). Characteristics Of Cooling Pipes : Excellent thermal stability Thermal shock-resistance Oxidization-resistance Creep persistence under high temperature Capacity to withstand strong wind in high temperature No deformation for a long term service

Die Casting Moulds

Get Price Quote

We are reckoned as the prime manufacturer and supplier of the highest grade die casting moulds. Our die casting moulds are highly acclaimed by the clients, owing to their efficiency and quality. Moreover, our die casting moulds are available in a wide variety, like bajaj cfl die casting moulds, box pressure die casting moulds, highbay pressure housing die casting moulds, side cover die casting moulds, wall pipe mounting pressure die casting moulds and led housing pressure die casting moulds. available in different sizes and shapesas per the client’s specific requirements attributes reusable steel moldshigh degree of accuracy & repeatabilitysharply defines the partssmooth or textured surfaces

Injection Mould Die

250,000 Per unit

Plastic Spoon Injection Mould

149,000 - 150,000 Per Piece

Mild Steel Plastic Trash Bin Mold

200,000 Per Piece

Silicone Mini Chocolate Mold

45 Per Piece

10 Piece (MOQ)

Injection Moulds

Get Price Quote

We offer Injection Molds in materials, sizes, and shapes as desired by our clients. The Injection Moulds we offer are dimensionally accurate and can be used repeatedly in the manufacturer of whatever product you chose to use it for. The Injection moulds we offer ensure that your finished product turns out impeccably and has a professional and uniform finish. We are a leading manufacturer and supplier from Mumbai, Maharashtra, India.

Molded Tool Packaging Thermocol Box

195 Per Piece

30 Piece (MOQ)

Moulded Coupler

20 - 50 Per Piece

1 Metric Ton (MOQ)

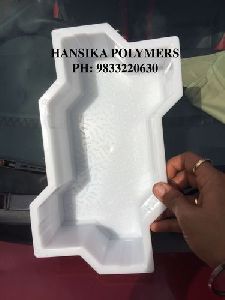

Pvc Paver Mould

Get Price Quote

50 Piece (MOQ)

Cosmic Paver Moulds

160 - 180 Per Kilogram

1 Ton (MOQ)

Pen Barrel Moulds

Get Price Quote

Plastic Mould

65 Per Piece

thermoplastic mold

Get Price Quote

Silicone Coaster Mold

75 Per Piece

Plastic Injection Mold

29,000 - 30,000 Per Piece

Plastic Pavers Moulds

Get Price Quote

The company is affianced in offering a gamut of Plastic Pavers Moulds all over the world. We are a reliable Manufacturer, Supplier and Exporter of Plastic Pavers Moulds in Maharashtra, India. Available in number of sizes, our Pavers are simple brick shaped with long service life. They come with increased design flexibility. Our Plastic Pavers Moulds are suitable for any type of area be it driveways, parking areas, pedestrian walkways or factory premises. Owing to our extensive network, timely delivery for the order has never been an issue with us.Sizes Available : 8"x8" 8"x4" 4"x4" 8"x12" 10"x10" 10"x5" 5"x5" 12"x12" 12"x6" 6"x6"