Compressed Air Piping System

Get Price Quote

1 piece (MOQ)

The compressed air needs to be delivered with enough volume, appropriate quality, and pressure to properly power the components that use the compressed air.A poorly designed compressed air system can increase energy costs, promote equipment failure, reduce production efficiencies, and increase maintenance requirements.It is generally considered true that any additional costs spent improving the compressed air pipe system will pay for themselves many times over the life of the system.

Ptfe Tubes

Get Price Quote

Best Deals from Industrial Plastic Pipes

Quartz Glass Spiral Tubes

250 Per Piece

1 piece (MOQ)

Transparent, Can be manufactured as per client’s required Specification

high pressure steel pipe

120 Per Kilogram

1000 Kilogram (MOQ)

cast nylon pipe

350 Per Kilogram

Hdpe Pipes,Cpvc Pipes

Get Price Quote

100 Meter (MOQ)

We are offering abs,pvdf,hdpe,cpvc,ppr,pvc,pp,pph,ppch,pert,pb,pex,gre, grp/frp, pipes&fittings.as a wholesale price we are a manufacturer importer,distributor of plastic pipes and fittings like abs,pvdf,pvc,hdpe,cpvc,ppr,pprc,pp-ch,pert,pb,pex,acrylic,polycarbonate,grp/frp,gre, pipes&fitting,also.pvdf,ectfe,pvc,hdpe,pph sheets from 1mm to 100 mm thick blocks,rod's any size and shape also in turn-key project of piping with all ultra modern machinery and technically sound teem works hdpe,pvc,pp,pph,pvdf,ectfe,grp/frp.epoxy,tanks &equipments pp,pvc,frp ducting cpvc,ppr,pert,pb,pex,ppch,pvc,hdpe,plumbing pipes with installations service available ex-stock abs pipes size 12 mm to 200 mm,pvc pipes 20 mm to 630 mm, pvdf pipes 20 mm to 315 mm ,ppr ,pp-ch,20 mm to 200 mm ,pp pipes 20 mm to 800 mm, hdpe 20 mm to 1600 mm acrilic 20 mm to 160 mm polycarbonate 20 mm to 160 mm, grp/frp 20 mm to 600 mm pp,hdpe sheets 1 mm to 100 mm thickness & pvc sheets 1 mm to 30 mm size 1.3 .

Helical Wound HDPE Pipe

Get Price Quote

PE Pressure & Non Pressure Structured Wall Pipes up to Ø4000mmKrah AG, the German machine manufacturer, has developed a complete production line to produce pressure pipes in diameters ranging from DN/ID 300mm to DN/ID 4000mm made of a compound of polythelene reinforced with fibres to unite the well-known properties of thermoplastics with the significant characteristics of fibers. The machine is designed similar to the well established KR Series production machines, applying the winding process to produce pressure pipes up to 10 bar working pressure. Moreover it can be upgraded to the characteristics of the conventional KR Machine, so that now one single machine, the so called KDR machine, is able to produce structured wall Non-Pressure Pipe Systems as well as solid wall PE-GFR Pressure Pipe Systems. However, the equipment is not only designed to manufacture the pipes themselves, but it is able to produce an integrated electro fusion joint and the complete range of fittings for pressure as well as non-pressure applications. High production output, enormous flexibility, short setup and change over times, simple operation, a perfect joint and more application facilities for the products are the main characteristics of all Krah machines. Moreover, the customer decides which pipe diameters are needed to satisfy the market requirements and he purchases only the necessary production tools for these pipe diameters. This allows the customer the optimum choice of equipment with the possibility to upgrade the equipment later by purchasing production tools in other diameters. Such an upgrade does not require any modifications to the machine. Furthermore every pressure class can be produced without the necessity to invest in further dies or special tools. Various formulations of high density polyethylene (PE 63, PE 80, PE 100) can be used to produce the requested end product, thus providing all positive characteristics compared to other stiff pipe materials like concrete, steel, etc. The DR Series is designed to produce, in the most economical and ecofriendly way pipes, fittings and manholes in diameters ranging from DN/ID 300mm to DN/ID 4000mm and in lengths from 1m up to 6m and on special request even longer, 6m pipe length has become a standard length because of their easy to transport and handling.

Ptfe Lined Pipe

Get Price Quote

gre pipe

Get Price Quote

The CBU focuses on conveying highly corrosive fluids. The unit cover the following industries : Chlor-Alkali Membrane Cell Plants SO2 SO3 Gas Cleaning Plants Power Plants ( Flue Gas Desulphurization systems – FGD)

Pex Pipes

Get Price Quote

Pex pipes Copper pipe adaptor, polish chrome plated for toweldryer. For plumbing systems.polish chrome plated for toweldryer

Ptfe Lined Pipe

Get Price Quote

Piping

Get Price Quote

Dipesh Engineering Works offers complete package with design, stress and load analysis, bellow selection, fixed and sliding saddle selection for cooling water lines.

FRP Pipes

500 - 600 Per Meter

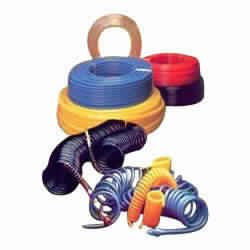

Polyurethane Coiled Tube

1,332 Per Piece

800 Piece (MOQ)

Blue Pressure HDPE Pipe

Get Price Quote

PTFE Extruded Tubing

Get Price Quote

We are reckoned as one of the most leading ptfe plastic tubing suppliers, based in india. Some of the features of our ptfe extruded tubing are listed below- features ptfe extruded tubing is manufactured by high pressure ptfe dispense resin mixed with additive, it is extruded and sintered. According to different demands, the tubing could be opaque or translucent. Ptfe is well known for its chemical resistance, not aging, non stick, self-lubrication, insulation and wide working temperature range from -180oc to +260oc. Because of these excellent properties, ptfe has a wide application in fields of chemical, mechanical, electronics, medical and aviation, etc. Applications our ptfe extruded tubes are used as wire and cable jacket, inner lined pipes for corrosive fluids and used in hydrochloric acid heat exchanger, etc. Specifications 0.8mm wall-thickness, 1.0mm wall-thickness, 1.5mm wall-thickness (pure virgin) ptfe tubings are available.

Polyurethane Tubing

Get Price Quote

Leading manufacturer, supplier and exporter, Hasolon Nylon Products Pvt. Ltd. has come out with yet another high end product, PU Tubing / Polyurethane Tubing which are designed for multiple applications which include air, pressure hydraulic, paint, food, printing and packaging machines and medical appliances. Lightness and flexibility like rubber over a range of temperature make this product compatible with so many applications. These PU Tubing which are perfect for air lines fabricated in textile machinery are resistant to all types of weather and have high strength for cutting. The tubes are resistant to flex cracking and can be identified for being multicoloured. Manufactured through a state of the art process by Hasolon, reputed as a manufacturer, exporterand supplier, these PU Tubing have good resilience which allows them to be mounted repeatedly to the pieces for connection preventing any cutting. Polyurethane having excellent resistance to grease, oils, oxygen, ozone and aliphatic hydrocarbons make this product so much feasible than any other materials. These PU Tubing are non toxic and has the property of stability while folding, which makes them ideal for being transformed into coil form. These PU Tubing are available in various sizes and can also be custom made to the size requirement. Applications : Pressure hydraulic and air machines. Paint Machines. Printing Machines. Packaging Machines. Medical Appliances. Analytical Apprataus. Food Machines. Compressed air lines on Pneumetic Control Systems. Air lines on textile machinery. Salient Features of Polyurethane Tubings Polyurethane Lightness - 9 times lighter than copper tublings. Rubber like flexibility over a wide range of temperature and hence radii of curvature can be very small withour flattening which causes loss of pressure. Resistance of all types of weathering. Polyurethane (PU) has Excellent resistance to oils, grease, aliphatic hydrocarbons, oxygen and ozone. Good resilience which allows repeated mounting on to the connecting pieces. (cutting off is not required) High cutting strength. Folding stability. Resistance to flex cracking. Multicolor for easy identification. Non-toxic Salient features for coil form Light Weight Space Saving Working Length - 2 metres to 20 metres. Working Pressure - upto 10 Kg/Cm².

Teflon Hose Pipe

Get Price Quote

The Teflon Hose Pipe offered by us is frequently used in several clinics and laboratories. The PTFE Teflon Hose Pipe we deal in is strong enough to withstand high pressure. It is resistant to various chemicals and high temperature, which makes it an ideal one to be used in laboratories. The Flexible Teflon Hose Pipe is non-sticky to almost all the chemicals which ensure 100% purity of the chemicals passed through it.

Teflon Hose Pipes

Get Price Quote

Teflon Hose Pipes, Stainless Steel Flexible Hoses, Corrugated Hoses

pneumatic tube

Get Price Quote

pneumatic tube, pneumatic tyre

Plastic Tube

Get Price Quote

PVC Lay Flat Discharge Hose

Get Price Quote

PVC Lay Flat Discharge Hose, Triangular Polishing Blocks, Sand Blasting Hoods

plastic tubing

Get Price Quote

plastic tubing, elastomer compounds, Filier Masterbatches

Grp Pipe

Get Price Quote

Grp Pipe

HDPE Pipe

Get Price Quote

boiler plate, Bimetallic Strip, Reducer Fittings, Flanges

HDPE Hoses

Get Price Quote

HDPE Hoses, Spring Balancers, Silicone, Nylon Braided, teflon tubings

pe tubings

Get Price Quote

pe tubings, silicone tubings, autoclave tapes, Disinfectant, Pipettes

Ptfe Thin Wall Tubing

Get Price Quote

Ptfe Thin Wall Tubing, ptfe micro powders

Pu Tubes

Get Price Quote

Pu Tubes, repairing, maintenance, pneumatic products solenoid valves

Pu Tubes

Get Price Quote

Pu Tubes, Biscuit Baking Plant, Pneumatic Cylinder, Pneumatic Products