Ceramic Infrared Heater

102 Per Piece

1000 Piece (MOQ)

Philips IRK Infrared Heater

2,430 - 10,000 Per Piece

1 piece (MOQ)

Best Deals from Infrared Heaters

Ceramic IR Heaters

Get Price Quote

Various types of heaters like Cartridge Heaters (Low watt & High watt density of various sizes), Ceramic Infrared Heaters (Elstein brand- Germany) and Short-wave infrared heaters are available with us.

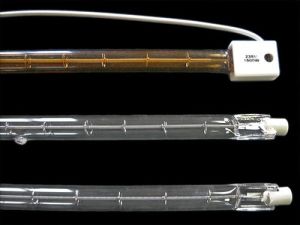

twin tube medium wave infrared heater

1,000 - 1,500 Per pc

1 Piece (MOQ)

Ceramic Infrared Heater

Get Price Quote

Ceramic IR Heaters

800 - 1,200 Per Piece

4 Piece (MOQ)

They are constructed by a firmly burnt-in heating coil. The heater incorporates highly heatproof resistance wire that provides safety against any damage. We supply Custom Wattage Infrared Ceramic Heaters as per the requirement of our clients. Longer service life is achieved since the resistance of the heaters is made to remain constant over the whole temperature range. The glaze used in this heater has excellent radiation properties therefore the radiation efficiency is also very high. Our Ceramic Infrared Heaters are available in 3 standard models:1. Full Length 245mm(FSR) 60mm 250 to 1000 W2. Half Length 122mm (FSR/2) 60mm 125 to 500 W3. Quarter Length 60mm (FSR/4) 60mm 60 to 250 W Features The material used for the production do not oxidize therefore the surface always remains clean and do not wear out As the coil is embedded in ceramic material, it can be installed in any possible position Application In Thermoforming & Vacuum Forming Machines In PVC Pipe Belling / Socketing Machines In Hot Stamping Machines As Heat Therapy Equipment, In Shrink Packaging

Ceramic Infrared Heaters

Get Price Quote

We are one of the leading manufacturers of infrared equipments and heating elements. Our Infrared equipments are made with latest technology and research to provide best quality for our customers. Our Ceramic Infrared Heaters are designed to produce maximum output in form of heat energy. They are constructed by a firmly burnt-in heating coil. The heater incorporates highly heatproof resistance wire that provides safety against much damage. We supply Custom Wattage Ceramic Infrared Heaters as per the requirement of our clients. Longer service life is achieved since the resistance of the heaters is made to remain constant over the whole temperature range. The glaze used in this heater has excellent radiation properties therefore the radiation efficiency is also very high. This heater is available with Color Changing Feature as Yellow Ceramic IR Heater (CC FSR). Our Ceramic Infrared Heaters are available in two standard models Full Length 245mm (FSR) 60mm 250 to 1000W Half Length 122mm (FSR/2) 60mm 125 to 50 Features The material used for the production do not oxidize therefore the surface always remains clean and do not wear out. As the coil is embedded in ceramic material, it can be installed in any possible position. Application In Thermoforming & Vacuum Forming Machines In PVC Pipe Belling/ Socketing Machines In Hot Stamping Machines As Heat Therapy Equipment In Shrink Packaging

CERAMIC IR HEATERS AND PANELS

Get Price Quote

FEATURES Surface temperature to 750 °C. Mid-to-far wavelength infrared heat source provides uniform heat over a large area. Primary emission in the 3 - 10 micron range (no visible light), which is the most efficient wavelength for heating of platics, paper, textiles, and drying of most solvents. Available with built-in type K thermocouple. Available in 122 x 60 mm, 245 x 60 mm, and 122 x 122 mm sizes. Available with pink surface that turns to gray when heating providing evidence of correct operation. Clean, non-contaminating, heat operation. Glaze-coated ceramic body with no surface flaking or oxidation as on metal sheath elements. Provides perfectly repeatable performance. Easily arranged in large arrays that may be set up and controlled in zones. Operating life over 5,000 hours minimizes machine downtime. Iron alloy element wire provides longer life than nickel-chrome alloy wires. Resistant to thermal shock. Heaters are not damaged if hit by water spray APPLICATIONS Plastics: Thermoforming Vacuum forming Curing extruded parts Drying Laminating Paper: Speed drying coated paper Adhesive activation Element Selection Wood/Furniture: Heating bonded/painted/ plastic coated components Drying same components Paint: Drying lacquers/finishes Baking lacquers/finishes Textiles: Drying dyed/printed fabric Curing latex coatings Food: Warming Baking Electronics: Preheat PCBs IR reflow ovens for Packaging: Heat shrink Forming Thin Film Deposition: Vacuum coating Ceramic: Drying glazes/pigments Printing: Ink drying

Infrared Heater Immersion Heaters

Get Price Quote

Tubular elements used for heating liquids (corrosive and non-corrosive) are known as immersion heaters. For corrosive medium, sheath of the element can be enclosed in metallic or non-metalic Element casing made of special alloy can be used for longerlife of the element.Available in ranges of 1 KW to 4.5 KW with adaptor fittings 1" B.S.P to 212 " B.S.P threaded brass flanges duly nickel Chromium plated. Heaters high rating are available on request with flanged connections. The Photographs are those of water 7 oil immersion heaters simultaneously. Air-conditioning, Pharmaceutical.chemical, textile, nuclear and many more industries.

Twin Tube Fast Medium Wave Infrared Heaters

Get Price Quote

IR wavelength between short wave and medium wave Response time around 1 ~2 seconds Average working life 7000 hours Gold or ceramic coating at rear side as a reflectors Dimensions 15x33mm Max. overall length up to 4M Vertical and horizontal emitters are available

Short Wave Infrared Heater

Get Price Quote

Made out of 8.2 to 8.5mm dia chrome Nickel Steel Tube for mounting on side of vessels. Easy to remove and clean. Fitted with junction box for terminating the power line suitable for alkaline solutions to 90C. PET preform heting in stretch blow moulding machines. Paint backing. Rubber coating drying. Soldering fusing in PCB industries. Sterilizing! mirror coating drying in glass industries. Printing ink drying in offset machines. Impregnation plants. Paper coating drying. All type of laminations. Preheating prior to embossing. Screen printing curing on T-shirt & textiles Machine . Metal : Drying of machinery parts and coatings Plastic : Heating of thermosetting or thermoplastic resin Preheating of shrink film or molds. Welding of resins Paper . Print : Drying of moisture Drying of ink for offset and gravure print Electronic.Electricity : Drying of soldering or resin coating, epitaxial growth instrument. Sputtering, cuing of marking ink Fiber : Drying of moisture or starching Coating : Drying of enamel and moisture Vacuum Heating : Vacuum evaporation and heating Casting : Preheating of molds

Shortwave Infrared Heaters

350 Per Piece

infra red heaters

Get Price Quote

An infrared heater is a body with a higher temperature which transfers energy to a body with a lower temperature through electromagnetic radiation. Depending on the temperature of the emitting body, the wavelength of the infrared radiation ranges from 780 nm to 1 mm. The relationship between temperature and wavelength is expressed by the Stefan-Boltzmann Law. No contact or medium between the two bodies is needed for the energy transfer. A rough classification of infrared heaters is Efficiency of Infrared Heaters Theoretically, the efficiency of an infrared heater is 100% as it converts nearly all electrical energy into heat in the filament. The filament then emits its heat by infrared radiation that is directly or via a reflector impinging on the product to be heated. Some energy is lost due to conduction or convection.For practical applications, the efficiency of the infrared heater depends on matching the emitted wavelength and the absorption spectrum of the material to be heated. For example, the absorption spectrum for water has its peak at around 3000 nm. This means that emission from medium-wave or carbon infrared heaters are much better absorbed by water and water-based coatings than NIR or short -wave infrared radiation.The same is true for many plastics like PVC or polyethylene. Their peak absorption is around 3500 nm. On the other hand, some metals absorb only in the short -wave range and show a strong reflectivity in the medium and far infrared. This makes a careful selection of the right infrared heater type important for energy efficiency in the heating process. Applications of Infrared Heaters IR heaters are used in industrial manufacturing processes including curing of coatings; heating of plastic prior to forming; plastic welding; processing glass; cooking and browning food. They are used when high temperatures are required, fast responses or temperature gradients are needed or products need to be heated in certain areas in a targeted way . Their application is difficult for objects with undercuts.They are also used to provide warmth to suckling animals whose mother cannot or will not provide them with natural warmth as well as to captive animals in zoos or veterinary clinics, especially for lizards and other reptiles, and tropical animals such as birds.IR heaters are used in low-temperature infrared saunas.

Short Wave Infrared Heater

Get Price Quote

Ceramic Infrared Heater

725 Per Piece

Ceramic Infrared Heater

700 Per Piece

Infrared Heater

Get Price Quote

We hold expertise in manufacturing and supplying high performance Infrared Heater. Infrared Heater, which we offer, is appreciated for raising the ambient temperature and warming the room. Made with top quality raw materials and components, the Infrared Heater is rust resistant and very durable. Clients can avail wholesale Infrared Heaters from us at very affordable prices.

Infrared Heaters

250 - 5,000 Per Piece

infra red heaters

Get Price Quote

Uses : Shrink packaging tunnels, laminating, thermo forming, plastic forming, fusing plastics, vulcanizing rubber, sterilization, sealing, food warming, electrostatic copying equipment, food processing, drying photo films equipment, curing rubber, drying textiles, drying sand cores, space heaters, thermal copying equipment, pet bottle & jar manufacturing etc. Infrared heaters are of 2 type : These are specially designed for application that requires infrared radiant heating. It is the most efficient source of radiant energy. Quartz heater can deliver near & far infrared wavelengths which is more effective than a single wavelength, capable of generating full heat output capacity in 40 to 50 seconds, and cool down in less than 15 seconds. They offer excellent life characteristics whether operated continuously or intermittently.Construction : Quartz heater consist of a helically wound resistance coil housed in pure vitreous silica fused quartz tube. The quartz tube is terminated with specially designed ceramic insulating caps. The ceramic caps are securely fastened to the quartz tube with high temperature cement. Quartz heaters are designed for horizontal mounting position. (2) Tubular Infrared Heater : These heaters are manufactured in single/dual U bend element. East mounting.Construction : It is made from Incolay tube. Swagged type construction, gives long life & no breakage. It can be used vertical or in any position.Working Temperature : 350°C to 800°C.While Placing Order : Please mention diameter, length, wattage, voltage, lead wire length, special features if any.

Ceramic Infrared Heater

Get Price Quote