Injection Moulding Dies

200,000 - 600,000 Per piece

1 piece (MOQ)

EPTIFAB Eptifibatide Injection

13,000 - 13,500 Per VIAL

10 INJECTIONS (MOQ)

Eptifibatide is used to prevent Heart attack. Eptifab Products side effects Common Side Effects of Eptifab are Bleeding, Decreased blood pressure. How Eptifab Products work Eptifibatide is an antiplatelet medication. It works by preventing the platelets from sticking together, thereby decreasing the formation of harmful blood clots.

Best Deals from Injection Moulds

hot runner mould

Get Price Quote

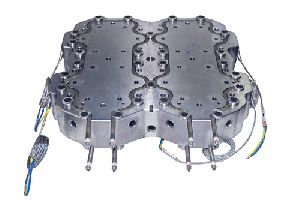

Euro Tech Hotrunner System has carved a niche for itself in the global markets as a successful Manufacturer and Exporter of Hot Runner Mould. Backed with years of industry experience and market understanding, we are offering a wide gamut of Hot Runner Mould that is manufactured with advanced technology and using supreme grade raw materials in sync with international quality standards. Features : 16 cavity White Cap Side Gate

Injection Moulding

Get Price Quote

We, Vikas Industry, produce best quality injection molded parts, also keeping in mind timely delivery and customer's requirements. We are leading manufacturer's of plastic injection molds in India. Injection molding, in a simple language is high pressure injection of Thermo plastic raw material into a mold to make it as a required shape. Molds are made up of stainless steel. These products vary from few grams to 2 kgs. Injection moulding is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould maker (or toolmaker) from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers which do not melt during the injection moulding of some lower temperature thermoplastics, can be used for some simple injection moulds.

Injection Moulds

Get Price Quote

The complete assortment of raw material sourced undergoes stern examinations by the professionals to keep the quality standards high. Owing to this, we are capable of bringing forth exceptional quality products. We have invested a large amount for developing storage unit that helps us in keeping a large stock for fulfilling urgent and massive requirements of the customers.

Plastic Injection Moulding Tool

100 - 2,500 Per No

Hello, We are the leading Manufacturers of Antivibration Machine Rubber Pads & various Industrial Rubber Products and Parts.

Dies & Moulds, Injection Blow Moulds, Press tool Dies, Fixtures, Machine Tool Maintenance

Get Price Quote

Machine Tool Engineers estd in the year 1996 is a proprietorship company based in Mumbai engaged in Machine Tool Manufacturing, Dies & Moulds, Injection Blow Moulding ,Special Purpose Machines Rebuild and Repairs & all types of Machining work

Injection Moulding

1,000,000 - 10,000,000 Per Piece

5 Piece (MOQ)

Kindly attn:- Owner / Chairman / Director / Managing Director / Authorised Purchase Head.Dear Sir,We are mfg of new moulds and Are Sole Agents for sales and services provider for Indian market with Dealing of New Injection Moulding Machine Range from 100T to 4000T with having excellent quality and at most competitive reasonable prices & More Beneficiary for the exporters of finished goods.Machinery suitable for Injection Moulded products as for below1.Automobiles2.Battery case3.Furniture and crates4.Caps & Closures5.Computer & Accessories6.Household7.Electrical & Electronics8.Engineering9.Food & Non food containers10.Medical labs11.Paint pails12.Lubricants13.Pet performs14.Pipe fittings15.Textile16.Thin wall containers17.Writing instruments stationery18.Houseware & KitchenwareAnd having all ancillary equipment for support of injection,blow and extrusion plant machinery to run in automation are as1.Hopper & Dryer2.Auto loader3.Mould Temperature Controller (MTC)4.Granulator5.Colour Mixer6.Chiller7.Cooling Tower8.Robot 9.Cleaning Agent for Complete plant water system10.Hotrunner & Controller11.Preventive Maintenance for moulds & machinery12.Annual Maintenance Contract Pls to let us know the exact requirement of machinery1.What kind of product and raw material uses2.What capacity of machinery in Tonnage3.Total Shot weight4.Maximum Mould Size (L x W x Ht)5.Type Toggle or Hydraulic6.Min & Max Cycle time 7.Require Fixed pump or VDP or Servo

Injection Moulds

Get Price Quote

We offer wide range of Injection moulds for different product applications: Moulds for household items like buckets, bowls, basins, mugs etc. Moulds for houseware / furniture / pallets / crate Moulds for turnkey project – PET preform / Thinwall IML system / Caps & closure systems / Audio-video-CD / Ball point pens Moulds for Home appliances Moulds for PVC fittings Moulds for auto-components

Two Plate Injection Moulds

149,000 - 150,000 Per Piece

Plastic Injection Mould

8,000 - 9,000 Per Piece

Thermoplastic Molds

Get Price Quote

Our mould system guarantees perfect frame with runner to direct the uniform flow of molten thermoplastic with cooling channels working in unison to control temperature and ejection system to provide finished moulded product of high quality. Marching ahead with the technological advances, we are adopting a new symbol reflecting moulds special characteristics of quality performance and master in Injection Moulding

Injection Mould Die

120,000 Per Piece

plastics injection molding

Get Price Quote

Using their years of experience and an advanced machining facility, ERIKS manufactures inhouse every type of final product. Starting from a sketched design, ERIKS manufactures plastic parts fully to specification. Flexible manufacturing allows the number of parts produced to vary from ones and twos to many thousands.

Plastic Molds

Get Price Quote

Plastic Injection Moulds

49,000 - 50,000 Per Piece

Injection Moulding

Get Price Quote

Injection moulding, Our product array includes Plastic Injection Moulding Machine, Vertical Injection Molding Machine, Injection Moulding Machine With Vertical Clamping and PET Injection Moulding Machine.Specially designed to cater for Moulding of Dimond wire ropes used for cutting of Marble and granites blocks in mines. This model is developed for specific use with 30 Tons Locking . Microprocessor controlled coupled with Hydraulic Locking with strong mechanical structure offers long life with Trouble free operations.

Injection Moulding Machines

Get Price Quote

We offer injection moulding machines and moulds. State-of-the-art microprocessor controlled plastic injection moulding machines. The injection moulding machine ranks among the company's many winning products.

CAZAT Injection

Get Price Quote

Injection Molded Plastic

Get Price Quote

Injection Molded Plastic, Plastic Caps

Injection Moulds

Get Price Quote

Injection Moulds, Injection Moulding

Injection Moulds

Get Price Quote

We are offering injection moulds.

Injection Molds

Get Price Quote

These are some injection molds we have manufactured in-house. We have catered to the Indian as well as international markets. To know more about us and understand our credibilty visit us on: Facebook:http://on.fb.me/x3CUyG Linked in:http://linkd.in/i9ql8d

precision injection molded plastics

Get Price Quote

precision injection molded plastics

INJECTION BLOW MOLDING

Get Price Quote

INJECTION BLOW MOLDING

Injection Moulding Machines

Get Price Quote

Injection Moulding Machines, Injection Moulding Machine

Injection Moulds

Get Price Quote

Injection Moulding ranks as one of the prime processes for producing plastics articles. It is a fast process and is used to produce large numbers of identical items from high precision engineering components to disposable consumer goods. Injection mouldings count for a significant proportion of all plastics products from micro parts to large components. Virtually all sectors of manufacturing use injection moulded parts - the flexibility in size and shape possible through use of this process have consistently extended the boundaries of design in plastics and enabled significant replacement of traditional materials thanks to light weighting and design freedom.

injection molded

Get Price Quote

injection molded, Fiber Glass Pultruded Grating

Injection Molding

Get Price Quote

Injection Molding, Single Bolt Cleat, Copper Tubular Lug, Plastic insulators

Injection Moulding

Get Price Quote

Injection Moulding, Polymers, Microwave, Blow Moulding, Petrochemical