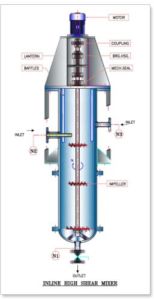

Inline High Shear Mixer

100,000 Per Piece

1 Piece (MOQ)

Inline Homogeniser Mixer

200,000 - 1,000,000 Per Piece

1 Piece (MOQ)

INLINE MIXERS (Pharmachem Cosmetics Industries):Usually called "high-shear mixers", are the most common form of Dispersing/Homogenising/ Emulsifying mixer. By placing a form of closely-fitting shroud around a high speed impeller, it is possible to create a shearing action between the blades and stator shroud. As material is centrifugally pumped through the mixing head, some of it will see this high shear zone and experience shear stressing that results in dispersive mixing. Where small or uniform dispersions are required, material must be cycled through the head many times to ensure statistically that all of the material has passed through the high shear zone at leastonce.PUMPING ACTION : Because of indigenous design & rotor operating at very high speed in close clearance with stator draws the material in & imparts mechanical & shearing actions. Inline Homogenizer facilitates high volume, non positive action which is sufficient to transfer the material without any supplementary pumps but in some cases because of high viscosity, vertical lift or length of pipe line , the flow rate may come down below the anticipated value, In that case it is supplemented by an auxiliary pump installed in the system which pumps the liquid without reducing the homogenising/emulsifying efficiency of the system.END CONNECTION : The inlet & outlet are normally fitted with . DIN, Tri Clover/ Sanitary Screw fittings but other Modes of fittings can be provided on request.SEALING : Single mechanical seal with Carbon, silicon carbonized phase combination is provided. Special single or double sealing is also available for conditions & process which demand it eg. Latex , Abrasive solids.APPLICATION OF INLINE HOMOGENISER/EMULSIFIER Inline emulsifier is successfully used for the following processes :RECIRCULATORY PROCESSING : Pharmachem Cosmetics IndustriesThere are certain processes which demand higher degree of homogenization, dispersion, comminution & but to attain that level, single passage of material through Inline is not sufficient to reach that degree , in that situation , it is more useful to pass the product several times through the same machine by means of recirculation. The above process is normally adopted in producing emulsion of Oil & Water. Oil , which is lighter than water is charged in the holding vessel & water is added into the pipe line between vessel outlet valve & Inlet of Inline Emulsifier. This mix is immediately sucked into the head of emulsifier & there mixing/ emulsification/ homogenization takes place . This mix is then sent into the vessel. This process is repeated till achievement of perfect emulsion. Where viscosity is very high or vessel size is large, it is recommended to go for Batch type mixer along with Inline Mixer.PREMIX PROCESS : In this process, all ingredient are mixed in a holding vessel with some agitator & a single passage through the inline smoothens the lumps and homogenize a suspension or emulsion.Inline Mixer is currently in use in the industry listed below & this gives a new horizon for this exceptional machine to validate its results. CREAMS DAIRY & CONFECTIONARY ITEMS BEVERAGE & BREWERY PAPER COATING PHARMACEUTICALS PESTICIDES & INSECTICIDES PAINTS NATURAL HERBAL DYE

Best Deals from Inline Mixers

Inline Homogenizer Mixer

Get Price Quote

1 Unit (MOQ)

Static Inline Mixer

Get Price Quote

We are one of the leading static inline mixer manufacturers, exporters, and suppliers in india. The static inline mixer, offered by us, has no moving parts and it utilizes the energy of the continuous flowing fluids itself. Our static inline mixer efficiently mixes solids, liquids, and gases in any combination. used for blendingdispersionheat exchangeemulsificationph controlflash mixingmass transferslurry suspensiongas-liquid contacting features of static inline mixer simple & compacthigh energy efficiencylow capital & operating costis used for continuous processhigh degree of operational safetyhave no moving parts and hence maintenance freehigh degree of mixing per unit of expended energysize can be selected to suit existing pipeline size available in all sizesdifferent end connections:flangedscrewedidf headsvarious materials:316 ss304 sscarbon steeltitaniummonelhastealloypolypropylenepolytetrafluroethylene [teflon]polyvinyl chloridefiberglass reinforced polyesterpp/frphigh density polyethylene

Vacuum Inline Homogenizer Mixer

Get Price Quote

Inline Homogeniser Mixer

50,000 Per Unit

1 Unit (MOQ)

Inline Homogeniser Mixer

Get Price Quote

Inline Homogenizer is made up of sturdy construction and can be moved from one place to another. It is necessary to mix one or more substances within a liquid. This device is been used to micronize and scatter the particles that are suspended in the fluid. This in turn makes the product highly stable. Inline Homogenizer delivers with the unparalleled consistency, control of high sheer process applications including Immiscible Phase Emulsifying, Homogenizing, Wet Grinding, Texturing, DE agglomeration and Fine Dispersing. Inline Homogenizers are been designed to handle different types of tasks including emulsifying, suspending, dispersing and blending.

Order Inline Mixer

Get Price Quote

Inline Mixer manufactured by Rufouz Hitek Engineers serve in all major industries related to the engineering fields. They are extensively used to smooth the progress of heat as well as mass transfer. The technique of gashing and reunification helps this device to becoming a great mixing equipment. They are able to ensure complete interruption free process. In such mixer fluids flow rapidly either from clockwise or anticlockwise direction to give consistency in product quality.

Inline Homogeniser Mixer

80,000 Per Piece

1 Piece(s) (MOQ)

Manufacturer of standard & custom inline homogenizers for mixing, homogenizing, emulsifying & blending applications. Features include mixing head with single rotating impeller & stator & unit motor coupled with coupling. In-line mixers mixes, homogenizers, emulsifies & blends additives, base liquids & uncoalesced substances. Mixers are available in 3 in. thru 48 in. pipe sizes in carbon & 304 & 316 stainless steel. Mixers & homogenizers also have mechanical seals to handle liquids up to 159 psi. Mixers & homogenizers can be mounted on existing piping & retrofitted into existing plant locations. Options include belt drives, speed drives & control systems.

Inline Static Mixer

15,000 Per Piece

1 Piece (MOQ)

Inline High Shear Mixers

Get Price Quote

Inline High Shear Mixers / Emulsifier High Shear Mixers are operated at high speeds more than 1000 Rpm with smaller Impellers and has typical design. The concept of High Shear Mixing is detailed in In Tank Processes. This can also be used Inline as shown below.

in line mixer

Get Price Quote

In the Inline, the work Head is set into a wall, which divides the machine into two separate chambers, one with the inlet tube attached and the other with the outlet. Because of this construction it is physically impossible for any material-liquid or solid – to pass from the inlet to the outlet without being subjected to the hydraulic and mechanical shear actions. The lower profile also permits its installation in area that are limited vertically. This, with other features, underlines its superiority over conventional COLLOID MILLS. The stators are available with perforations of different sizes and shapes. This makes it possible to adopt any machine to a variety of different processing operations including blending, mixing, emulsifying, homogenizing, disintegrating solids and suspending.

Inline Homogenizer Mixer

80,000 Per Piece

Inline Homogeniser Mixer

Get Price Quote

Inline Homogeniser Mixer, Rapid Mixer Granulator

Inline High Shear Mixer

Get Price Quote

Inline High Shear Mixer, Zero Hold Up Filter Press, Sparkler Filter Press

Static Inline Mixers

Get Price Quote

Static Inline Mixers, Thermosyphon System for Mechanical Seal, fluid agitator

Inline Mixer Machine

Get Price Quote

Inline Mixer Machine, Hermetic Pressure Leaf Filter, polish filter