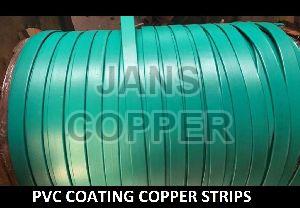

PVC Coating Copper Strips

Country of Origin : India

Type : Pvc Strip

Material : Pvc

Feature : Durable, Flexible Light, Stable Performance

...more

Phosphorus Copper Anode

460 Per Kilogram

Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications Product Description:Phosphorous Copper Anode (Cu-DHP) finds usage in the plating of Printed Circuit Boards. These anodes are available in Copper Ingots, Copper Cathodes and Electrolytic Copper options with all copper forms containing in it least 99.9% copper. Free from impurities, these provide the safeguard from contamination of electroplating solutions as well as a Co deposit on the cathode. Further, these are also available in suitable metallurgical condition to dissolve uniformly.General Specifications: Size - Oval - 80mm x 30mm; Ball minuscule 25mm, minuscule 38mm, minuscule 50mm or as per customer requirement Material Standard- ASTM B265, Grade 5, Grade 9 Shape- Oval, Ball Weight - per foot Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications Substance resulting from metallurgic processing of primary sources (copper matte obtained from copper ore/concentrate) and/or secondary sources (copper scrap and/or black copper) and including recycled intermediates (i.e. spent anodes and removal cathodes). Composed primarily of copper metal and copper oxides (> 80%) and containing other residual metals and their compounds. The raw material for a copper anode comes from one of two places; the copper is either refined or scrap material. Refined copper comes in the form of a copper cathode, named so because copper is electrolytically refined (plated out of solution). In this process, blister copper (approximately 95% copper) is dissolved anodically and high purity copper metal is plated slowly on a cathode with the impurities falling to the bottom of the plating tank as sludge. The impurities in the sludge include iron, sulfur, tellurium, selenium, gold, silver, zinc, arsenic, and others. The resulting cathode is 99.95% pure copper and can now be melted to form anodes. Scrap copper is generated daily around the world from such sources as utility wires, telephone wires, transformers, water tubes, buss bars, and other sources. This material is usually grouped and sorted by a scrap dealer. The disadvantage of scrap metal is its potential for contamination. All of the previously mentioned sources contain steel, tin, silver, and/or lead. The metals can also be mixed when sorting, and copper alloys can be mistaken for pure copper. Some metallic impurities in copper anodes can be dissolved and plated. These dissolved impurities will increase in concentration over time, resulting in a bath saturated with metallic contaminants. Plated impurities can cause stress and roughness on the plated part, which, in turn, cause difficulties in plating and process control, higher additive consumption (brightener) and scrap parts. These impurities usually go undetected until production problems appear because they are not normally examined in routine analysis.Grain Structure. The grain structure is the most important characteristic of copper anodes; this structure is completely determined by the process used to manufacture the anodes, which we will now explore. Casting of copper anodes is the simplest and least costly method; however, cast copper anodes do not exhibit the fine, uniform grain structures necessary for superior plating. Higher casting speeds will increase production and reduce costs, but will also result in larger grain size, and, therefore, inferior grain structure. Treatment is required subsequent to casting in order to produce copper anodes with a fine grain structure. This usually involves hot rolling, hot extruding, or hot forging. When the copper is formed under high temperature and pressure the grain structure is reformed and becomes fine and uniform. It should be noted that copper used for a variety of functions, other than anodes, require fine grain structures (wire, buss bars, copper foil and sheets). Overall, copper anodes containing higher impurities and without a fine grain structure will dissolve unevenly, have a higher sludge yield, result in lost copper dropping into solution, and have the potential to increase the roughness of plated parts. The results below show the sludge weight left in solution after 30 minutes of plating at 15ASF with four different types of copper anode balls. Filtered Solution (Weight of Sludge). Phosphorus content. Phosphorus content for acid copper plating is ideally maintained between 0.040 and 0.065%. Metallurgically, impurities are located at grain boundaries. Therefore, phosphorus (required for acid copper plating) is most evenly distributed in fine grain anodes. Typically, a black film develops as a result of the phosphorus in the anode. This film keeps fine pieces of copper from falling off of the anode as sludge and also retards corrosion of the anode. Anodes with large grain structures will develop a black film, but this film will not be adherent and quickly turn into sludge. The sludge now contains usable copper (lost metal) that can plug up anode bags and fall into solution causing roughness on plated parts.Cleanliness. Manufacturing oils, oxidation, and burrs must be removed from copper anodes. Copper oxidizes when it freezes from the molten state or when heated for rolling, forging, or extruding. This oxidation must be removed either by mechanical abrasion or acid pickling followed by neutralization. Mechanical methods are preferred because there is no residue. In the manufacture of bar anodes sawing, drilling, and tapping oils are used to lubricate the tooling. The oils are applied to the copper as well as the tooling. Proper washing and rinsing removes these residual oils or coolants (organic compounds) which would contaminate the plating bath. Anode nuggets are typically made by cutting copper rod into various lengths. This shearing process creates burrs and sharp edges that can drop into tanks or cause the nuggets to bridge or nest in titanium mesh baskets, causing voids of anode, uneven plating distribution, and anode polarization. In addition, burrs and sharp edges are hazards to the operators handling the material. Anodes should be inspected carefully to determine that the material has come from the manufacturer ready for use with no pretreatment necessary. Anode balls are formed by either cold forging (heading) or hot roll forging copper rod of various thickness. Copper wire being headed should preferably already have a fine grain structure. Normally copper balls that are hot roll forged will have a post-treatment procedure to ensure they will have a fine grain structure.

Type : Copper Anode

Material : Copper, Pure Copper

Shape : Round, Ball

Thickness : 10-20mm, 20-30mm, 30-40mm, 40-50mm, 50-60mm, 60-70mm, 70-80mm, 80-90mm, 90-100mm

Certification : ISI Certified

Length : 1-1000mm, 1000-2000mm, 2000-3000mm, 3000-4000mm, 4000-5000mm

Application : Earthing, Making Power Battery, Plants, Wire, Printed Circuitry

Color : Brown, Light Brown, Red

Feature : Corrosion Proof, Excellent Quality, Fine Finishing, High Strength, Perfect Shape

Finishing : Non Polished, Polished

Country of Origin : India

Textures : Solid

...more

phosphorised copper balls

520 Per Kilogram

Product Description:Phosphorous Copper Balls (Cu-DHP) finds usage in the plating of Printed Circuit Boards. These balls are available in Copper Ingots, Copper Cathodes and Electrolytic Copper options with all copper forms containing in it least 99.9% copper. Free from impurities, these provide the safeguard from contamination of electroplating solutions as well as a Co deposit on the cathode. Further, these are also available in suitable metallurgical condition to dissolve uniformly.General Specifications: Size - Oval - 80mm x 30mm; Ball minuscule 25mm, minuscule 38mm, minuscule 50mm or as per customer requirement Material Standard- ASTM B265, Grade 5, Grade 9 Shape- Oval, Ball Weight - per foot Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications. Jans Copper Pvt Ltd is one of the leading Copper Ballss, Copper Balls & Copper Nuggets manufacturer and supplier in India. Jans Copper Pvt Ltd's Copper Ballss, Copper Balls & Copper Nuggets are manufactured in accordance with the defined international standards. The raw material that is used to manufacture SIMCO copper products are LME grade ‘A’ cathodes of purity greater than 99.99% copper resulting in higher conductivity, crack free extrusion, excellent finish and longer life. Available Sizes As per customer’s requirement Available Grades ETP, OFC, Phosphorised Copper Plating / Coating Bare Additional Specifications / Details Available in all forms i.e. Oval, Slabs, Balls, Rods, Nuggets, etc. Applications / Uses Printed circuit boards, Rotogravure, Electroforming, etc. Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications Product Description:Phosphorous Copper Balls (Cu-DHP) finds usage in the plating of Printed Circuit Boards. These ballss are available in Copper Ingots, Copper Cathodes and Electrolytic Copper options with all copper forms containing in it least 99.9% copper. Free from impurities, these provide the safeguard from contamination of electroplating solutions as well as a Co deposit on the cathode. Further, these are also available in suitable metallurgical condition to dissolve uniformly.General Specifications: Size - Oval - 80mm x 30mm; Ball minuscule 25mm, minuscule 38mm, minuscule 50mm or as per customer requirement Material Standard- ASTM B265, Grade 5, Grade 9 Shape- Oval, Ball Weight - per foot Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications Substance resulting from metallurgic processing of primary sources (copper matte obtained from copper ore/concentrate) and/or secondary sources (copper scrap and/or black copper) and including recycled intermediates (i.e. spent balls and removal cathodes). Composed primarily of copper metal and copper oxides (> 80%) and containing other residual metals and their compounds. The raw material for a copper balls comes from one of two places; the copper is either refined or scrap material. Refined copper comes in the form of a copper cathode, named so because copper is electrolytically refined (plated out of solution). In this process, blister copper (approximately 95% copper) is dissolved anodically and high purity copper metal is plated slowly on a cathode with the impurities falling to the bottom of the plating tank as sludge. The impurities in the sludge include iron, sulfur, tellurium, selenium, gold, silver, zinc, arsenic, and others. The resulting cathode is 99.95% pure copper and can now be melted to form ballss. Scrap copper is generated daily around the world from such sources as utility wires, telephone wires, transformers, water tubes, buss bars, and other sources. This material is usually grouped and sorted by a scrap dealer. The disadvantage of scrap metal is its potential for contamination. All of the previously mentioned sources contain steel, tin, silver, and/or lead. The metals can also be mixed when sorting, and copper alloys can be mistaken for pure copper. Some metallic impurities in copper ballss can be dissolved and plated. These dissolved impurities will increase in concentration over time, resulting in a bath saturated with metallic contaminants. Plated impurities can cause stress and roughness on the plated part, which, in turn, cause difficulties in plating and process control, higher additive consumption (brightener) and scrap parts. These impurities usually go undetected until production problems appear because they are not normally examined in routine analysis. Grain Structure. The grain structure is the most important characteristic of copper ballss; this structure is completely determined by the process used to manufacture the ballss, which we will now explore. Casting of copper ballss is the simplest and least costly method; however, cast copper ballss do not exhibit the fine, uniform grain structures necessary for superior plating. Higher casting speeds will increase production and reduce costs, but will also result in larger grain size, and, therefore, inferior grain structure. Treatment is required subsequent to casting in order to produce copper ballss with a fine grain structure. This usually involves hot rolling, hot extruding, or hot forging. When the copper is formed under high temperature and pressure the grain structure is reformed and becomes fine and uniform. It should be noted that copper used for a variety of functions, other than ballss, require fine grain structures (wire, buss bars, copper foil and sheets). Overall, copper ballss containing higher impurities and without a fine grain structure will dissolve unevenly, have a higher sludge yield, result in lost copper dropping into solution, and have the potential to increase the roughness of plated parts. The results below show the sludge weight left in solution after 30 minutes of plating at 15ASF with four different types of copper balls balls. Filtered Solution (Weight of Sludge). Phosphorus content. Phosphorus content for acid copper plating is ideally maintained between 0.040 and 0.065%. Metallurgically, impurities are located at grain boundaries. Therefore, phosphorus (required for acid copper plating) is most evenly distributed in fine grain ballss. Typically, a black film develops as a result of the phosphorus in the balls. This film keeps fine pieces of copper from falling off of the balls as sludge and also retards corrosion of the balls. Ballss with large grain structures will develop a black film, but this film will not be adherent and quickly turn into sludge. The sludge now contains usable copper (lost metal) that can plug up balls bags and fall into solution causing roughness on plated parts. Cleanliness. Manufacturing oils, oxidation, and burrs must be removed from copper ballss. Copper oxidizes when it freezes from the molten state or when heated for rolling, forging, or extruding. This oxidation must be removed either by mechanical abrasion or acid pickling followed by neutralization. Mechanical methods are preferred because there is no residue. In the manufacture of bar ballss sawing, drilling, and tapping oils are used to lubricate the tooling. The oils are applied to the copper as well as the tooling. Proper washing and rinsing removes these residual oils or coolants (organic compounds) which would contaminate the plating bath. Balls nuggets are typically made by cutting copper rod into various lengths. This shearing process creates burrs and sharp edges that can drop into tanks or cause the nuggets to bridge or nest in titanium mesh baskets, causing voids of balls, uneven plating distribution, and balls polarization. In addition, burrs and sharp edges are hazards to the operators handling the material. Ballss should be inspected carefully to determine that the material has come from the manufacturer ready for use with no pretreatment necessary. Copper balls are formed by either cold forging (heading) or hot roll forging copper rod of various thickness. Copper wire being headed should preferably already have a fine grain structure. Normally copper balls that are hot roll forged will have a post-treatment procedure to ensure they will have a fine grain structure. Overall, there are several characteristics that determine the quality of the copper anodes manufacturing process. These include: purity of copper, fine grain structure, uniform phosphorus content and distribution, and properly cleaned and anodes packaged and ready for use. Therefore, the quality of copper anodes should be very important to electroplaters because properly manufactured anodes will: extend bath life; have less metallic contamination; produce parts without roughness; have less sludge; and require less maintenance.

Country of Origin : India

Type : Copper Balls

Material : Copper

Shape : Round

Color : Red, Dark Brown

Feature : Perfect Shape, Good Quality, Fine Finishing, Eco Friendly, Durable, Superior Finish

Pattern : Plain

Condition : New

Size : As Per Requirement

Brand Name : Jams Copper

Application : Electronic Components Connecting, Electroplating

...more

Oxygen Free Copper Anode

445 Per Kilogram

Product Description:Phosphorous Copper Anode (Cu-DHP) finds usage in the plating of Printed Circuit Boards. These anodes are available in Copper Ingots, Copper Cathodes and Electrolytic Copper options with all copper forms containing in it least 99.9% copper. Free from impurities, these provide the safeguard from contamination of electroplating solutions as well as a Co deposit on the cathode. Further, these are also available in suitable metallurgical condition to dissolve uniformly.General Specifications: Size - Oval - 80mm x 30mm; Ball minuscule 25mm, minuscule 38mm, minuscule 50mm or as per customer requirement Material Standard- ASTM B265, Grade 5, Grade 9 Shape- Oval, Ball Weight - per foot Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications. Jans Copper Pvt Ltd is one of the leading Copper Anodes, Copper Balls & Copper Nuggets manufacturer and supplier in India. Jans Copper Pvt Ltd's Copper Anodes, Copper Balls & Copper Nuggets are manufactured in accordance with the defined international standards. The raw material that is used to manufacture SIMCO copper products are LME grade ‘A’ cathodes of purity greater than 99.99% copper resulting in higher conductivity, crack free extrusion, excellent finish and longer life. Available Sizes As per customer’s requirement Available Grades ETP, OFC, Phosphorised Copper Plating / Coating Bare Additional Specifications / Details Available in all forms i.e. Oval, Slabs, Balls, Rods, Nuggets, etc. Applications / Uses Printed circuit boards, Rotogravure, Electroforming, etc. Overall, there are several characteristics that determine the quality of the copper anodes manufacturing process. These include: purity of copper, fine grain structure, uniform phosphorus content and distribution, and properly cleaned and anodes packaged and ready for use. Therefore, the quality of copper anodes should be very important to electroplaters because properly manufactured anodes will: extend bath life; have less metallic contamination; produce parts without roughness; have less sludge; and require less maintenance.

Country of Origin : India

Type : Copper Anode

Material : Copper

Thickness : 10-20mm, 20-30mm, 30-40mm, 40-50mm, 50-60mm, 60-70mm, 70-80mm, 80-90mm, 90-100mm

Length : 1-1000mm, 1000-2000mm, 2000-3000mm, 3000-4000mm, 4000-5000mm

Application : Earthing, Making Power Battery, Plants, Cryogenic Refrigerator Compressors

Brand Name : Jams Copper

...more

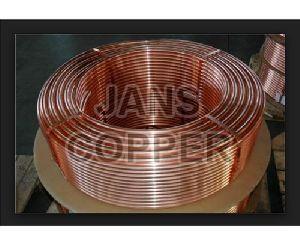

LWC Copper Tubes

510 Per Kilogram

500 Kilogram (MOQ)

The Level Wound Coil (LWC) Copper Tubes is one of our imported & supplied products. All LWC tubes are normally produced according to ASTM & Coproclima specifications. These specifications were prepared to take account of the requirements of ACR industry. Each millimeter of tubes is 100% Eddy-Current tested and any surface defects found will be clearly marked by black color. For heavy coils, we wound LWC copper tubes in "Eye to Sky" (Jumbo) form as per customer request. The tube is cleaned with Nitrogen purging. Moreover to protect the tubes against dust & internal oxidation during transportation or long storing, the tube ends are sealed with plastic caps. Jans Copper Pvt Ltd deliver LWC with cardboard reels. Coils on reel are stacked on wooden pallets and shrink wrapped. Level Wound Coils are specially suited to long production runs for industrial applications and it is widely applied to the Air Conditioning & Refrigeration as well as the Heat Exchanger field. Most commonly supplied in the soft and light annealed form, also Level Wound Coils can be ordered in hard drawn temper. Technical Specification Specification: O.D: 3/16" to 3/4" (4.76 to 19.05 mm) Coil Weight: 100-400 Kg Application: Applied to the Air Conditioner, the Assembly Type Air Conditioning Unit, Refrigerator, Freezer, Chest, etc.

Type : Seamless

Material : Copper,Pure Copper,Phosphorus Deoxidized Copper & Oxygen Free Copper

Thickness : 0-5mm,10-15mm,15-20mm,20-25mm,5-10mm,0.27mm Onwards

Certification : ISI Certified

Length : 1-5Mtr,10-15Mtr,15-20Mtr,5-10Mtr

Application : Construction,Industrial

Color : Brown,Golden

Feature : Durable,Eco Friendly,Fast Supply,High Strength,Non Breakable,Purity,Rustproof

Condition : New

Outer Diameter : 10-20mm,20-30mm,30-40mm,40-50mm,50-60mm,60-70mm,70-80mm,80-90mm,90-100mm,4 Mm To 25.4 Mm

Country of Origin : India

Brand Name : Jans Copper

...more

Lead Sheathed Copper Tape

510 Per Kilogram

Country of Origin : India

Type : Copper Tapes, Lead Sheathed

Material : Copper

Thickness : 1.5mm, 2-3mm

Certification : ISI Certified, ISO 9001:2008 Certified

Color : Brown, Dark-brown, Red-brown

Design : Plain

Width : 1inch, 2inch, 3inch, 4inch

Packaging Type : Corrugated Box, Paper Box, Plastic Box

Side : Double Sided, Single Sided

Brand Name : Jans Copper

Grade : ETP, OXYGEN FREE

Adhesive : Strong

...more

Lead Free Brass Rods

380 Per Kilogram

Material : Brass

Thickness : 1.6 Mm To 50 Mm

Brand Name : Jams Copper

...more

Laminated Copper Busbars

620 Per Kilogram

5 Kilogram (MOQ)

Product Description: Copper Laminated Busbars comprise flexible laminated copper connections that are produced using highly conductive electrolytic grade copper foil & sheets. These laminated Busbars undergo press welding where individual copper strips are fused through applying direct current as well as pressure, which results in ensuring minimum resistance as well as in enhancing the product life as well as in the reduction of downtime. Further, these also feature superior mechanical & electrical properties at higher temperatures. These also feature higher power density as well as better electromagnetic compatibility (EMC). Laminated Busbar is applied to implementing the connection of power devices in electric and electronic products. Through the parallel and laminated structure of the positive and negative electrodes, the inductance distributed among the circuit is reduced, which helps reduce the peak reverse voltage of both ends of the power elements and lower the requirements of voltage protection and circuit absorbing. This structure is aimed at improving the reliability and stability of power devices and the circuit integration for easier repair and maintenance. Laminated Busbar could be customized or specified according to your design or drawings. It also could be designed and developed according to your application and requirements. We are making various types of Profile busbars . These busbars are produced on Fibre optic laser machine and water jet cutting machine to get the required profile and accuracy .

Size : 0-15mm,15-30mm,30-45mm,45-60mm,60-75mm,75-90mm,90-105mm

Shape : Hexagonal,Round,Square

Thickness : 0-5mm,10-15mm,5-10mm,2 Mm

Application : Battery Bank,Substation,Switchboard,Aerospace & Military Appllications

Color : Copper,Metallic

Feature : Accuracy Durable,Auto Reverse,Corrosion Resistance,Dimensional,Extra Stronger,Hardend & Temper,High Quality,High Tensile

Voltage : 110V,220V,380V,440V

Surface Finishing : Polished,Power Coated

Standard : ASTM D4014,CE EN 1337-3,IEC-60137:2008,ASTM

Country of Origin : India

Depth : 0-10mm,10-20mm,20-30mm,30-40mm,40-50mm,50-60mm,60-70mm,70-80mm

Automation Grade : Automatic,Hydraulic,Riveting

Brand Name : Jans Copper

Material : Copper

...more

high tensile brass rods

340 Per Kilogram

Material : Brass

Shape : Round

Thickness : 0.27 Mm To 6.35 Mm

Brand Name : Jams Copper

...more

free cutting brass rods

330 Per Kilogram

Type : Brass Rods

Material : Brass

Shape : Round

Thickness : 0.5-1mm,1.5-2mm,2.5-3mm,3.5-4mm,4.5-5mm,5.5-6mm,6.5-7mm,7.5-8mm,8.5-9mm,9.5-10mm,2.74 Mm To 6.35 Mm

Certification : ISI Certified

Length : 100-200mm,200-300mm,300-400mm,400-500mm

Application : Welding Purpose

Feature : Corrosion Resistance,Easy To Fit,Fine Finished,High Performance,Premium Quality,Tensile Strength

Power Source : Electric

Country of Origin : India

Brand Name : Jans Copper

Grade : ETP, OXYGEN FREE

...more

forging brass rods

329 Per Kilogram

Material : Brass

Thickness : 0.27 Mm To 6.35 Mm

Brand Name : Jams Copper

...more

Forged Copper Clamp

Forged copper clamp is a used as a replacement for brass contact pad as they are far superior and cost effective than the brass ones. Our forged copper clamps are leak proof and are free of blowholes. We are one of the superior forged clamp manufacturers and copper clamps exporters from india. Useful for various purposes, the forged copper clamps are made available by us in a variety of sizes. Accurate design, finely finished surface, high corrosion resistant abilities are some of the defining features of the forged copper clamp brought forth by us. Consequently, we have carved a niche amidst the major forged clamp manufacturers and exporters from india. general properties : material with minimum copper content of 99.9% as per is191. size : as per customer`s specifications. fields of application calcium carbide unit ferro alloys industries alloy steel plant

Material : Copper

Finishing : Polished

Color : Copper colour

Structural Shape : Different shapes

Speciality : Easy To Fit, Compact Size, Perfect Shape

Usage : Industrial

Warranty : 1 Year

Country of Origin : India

...more

flexible copper links

620 Per Kilogram

The complete range of Flexible Copper Products includes Copper Flexible Laminated, Copper Flexible Braid, Copper Flexible Link and Copper Flexible Bus Bars. Here, our expertise lies in matching up with the complete demands of the customers including in varied usage environment. Further, these flexible copper products also feature superior electrical & mechanical properties at high temperatures.These are also made available in all sizes matching up to the demands of different cross section areas. Here, we can also offer these in other customized finish specifications as per the specific requirements of the customers. Product Details: Usage/Application Power Plants, switchgear industries Size As per requirement Standard & Material ASTM B33, ASTM-D-149 Area of Applications Switchgear industries,Power plants,Cathodic Protection,Bus Ducts,Transformer,V.C.B. Brand Jans Copper Pack Size As per customer requirement Product Description: Laminated and Flexible Copper are developed from high conductivity based electrolytic grade copper sheets/foils. These are made using a press welding procedure where individual copper strips are fused through applying direct current as well as pressure without the need of foreign material.The process assures minimum resistance and helps in increasing product’s service life as well as bringing a reduction in downtime. Further, these also come with superior mechanical electrical properties at high temperatures. General Properties: Standard Material - ASTM B33, ASTM-D-149 Application Areas: Switchgear industries Power plants Cathodic Protection Bus Ducts Transformer V.C.B. Resistance welding engineering Electric Locomotives Galvano Engineering Furnace RequestCallback Additional Information: Delivery Time: As per requirement

Type : Copper Links

Material : Copper, Fine Copper

Diameter : 12.7-25.0 Mm

Color : Red-brown

Feature : Cost Effective, Durable, Efficient, Fine Finished, Quality Approved, Variety Of Dimensions

Condition : New

Finishing : Coated, Polished

Width : 1-100 Mm, 100-200 Mm, 200-300 Mm

Standard : ASTM B33, ASTM-D-149, BS Standard

Country of Origin : India

...more

Flexible Copper Connectors

660 Per Kilogram

Application Areas: Switch Gear industries Power plants Cathodic Protection Bus Ducts Transformer V.C.B. Resistance welding engineering Electric Locomotives Galvano Engineering Furnace Copper, which has chemical symbol as Cu and atomic weight 29, is the most widely used metal in electrical and Manufacturing industry. Electronics component such as integrated circuits, electro-magnets and printed circuit boards are created using copper and products related to copper. Electrical Connectors use the mechanical assembly to connect or join electrical circuits to be used as an interface. Due to the nature of operation, an electrical connector needs to be manufactured using precise configuration and calculations. Copper wires are the most widely used metals for creating electrical conductors. Copper, has the maximum electrical conductivity and thermal conductivity which makes them as an ideal material for Manufacturing electrical connectors. Braided flexible connectors and jumpers are important components of electronics industry. These are manufactured using copper as well as stainless steel bellows, which are sometimes covered to provide additional strength and support. The main purpose of braided flexible connectors is to deliver maximum power output, even during peak performance. In those sectors, where the demand of power is much, and the wires experience considerable load, then braided flexible connectors can be an efficient solution for optimal power output. Some of the advantages of using braided flexible connectors are: · Control and absorb the vibrations · Manage the natural expansion and compression of wires during power transmission · Provide minimum resistance for seamless productivity Braids made of many copper wires are also sometimes used for flexible electrical connections between large components. The numerous smaller wires comprising the braid are much more resistant to breaking under repeated motion and vibration than is a cable of larger wires. In electrical and electronic cables, braid is a tubular sheath made of braided strands of metal placed around a central cable for shielding against electromagnetic interference. The braid is grounded while the central conductor or conductors carry the signal. - High conductivity copper - Wire to Bs - 4109 - C101 - Suitable for Earth Bonding/ also supplied as Standard Drilled & Pre-Cut Bonds. - Customer specific sizes & types of braid can be manufactured on order. Even though many of our products are standard items, we also make special tailor made products made exactly to the requirements of our customers. Electrical engineers in power generation are aware of this simple fact: Vibration is an enemy of electrical connectivity.

Type : Copper Links

Material : Copper

Diameter : 12.7-25.0 Mm

Color : Red-brown

Feature : Cost Effective, Durable, Efficient, Fine Finished, Quality Approved, Variety Of Dimensions

Condition : New

Finishing : Coated, Polished

Width : 1-100 Mm, 100-200 Mm, 200-300 Mm

Standard : ASTM B33, ASTM-D-149

Country of Origin : India

...more

flexible copper busbar

620 Per Kilogram

Thickness 1mm To 60mm Standard IS Brand Name Jams Copper Width 5mm to 350mm Edge Type Radius Corner Edge, Square Edge, Full Radius Edge Application Medical, Automotive Industries, Power Distribution, Telecommunication Edge Length Up to 6400mm (21`) Uses Bus Bars, Transformer Connectors, Power Transmission equipment, Control Panels Standard overall cutting tolerance 100mm Copper percentage 99.99 Additional Information Min. Order Quantity 100 Kilogram insulated flexible copper bars are mainly utilised for providing the power connections between busbars and the disconnection devices within an electrical panel. The insulated layered copper allows the flexible copper bar to be easily formed to provide a customised solution. Advantages Easy to install • Compact version. • High level of flexibility enabling easy manipulation of the busbar. • Reduced installation time with the elimination of terminal lugs and their crimping. Increased safety by the elimination of crimped connections • Better behaviour under short-circuit conditions. • Decreased number of heating points. • More reliable connections.

Thickness : 0.8 To 1 Mm

Standard : TU2

Brand Name : Jams Copper

Material : Copper

Application : Automotive Industries, Power Distribution, Telecommunication

...more

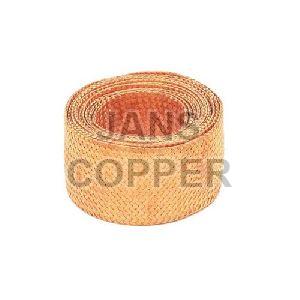

flexible copper braids

535 Per Kilogram

Our super flexible flat copper braids (copper tapes) are made to order from 0.05 mm diameter wire are braided into a tube followed by a rolling process to flatten them to the specified width and thickness. They are used as earthing straps and in numerous electrical components. These super flexible flat copper braids can be made in electrolytic copper Cu-ETP (grade C101) or oxygen free copper and in a wide range of finishes. Tin plated super flexible copper braid is made from 0.071 mm dia wire. The braid can be folded back on itself, as shown in the pacture. All our copper braids are RoHS compliant.

Material : Copper

Application : Grounding Bars

Thickness : 1.0 to 3.0 mm

Brand Name : Jams Copper

...more

Flexible Connectors

Jans overseas presents a special range of flexible connectors in the market, which is widely acclaimed for its matchless quality. Braided flexible connectors are manufactured by us in compliance with the set industry standards while using the best materials sourced from trusted vendors. As a prominent flexible connectors manufacturer and exporter, we have gained appreciation from clients all over the world by supplying a range for diverse applications. Besides, we ensure to inspect every batch of the flexible connectors in terms of their appropriate design, us of best material and manufacturing techniques so theta the range is flawless in every aspect. our flexible copper connectors, braided flexible connectors etc combine maximum conductivity & minimum voltage drop, without the loss of flexibility in the braid. Our flexible connectors are available for quite competitive prices as well. We are one of the dependable flexible connectors exporters from india.

Material : Copper

Color : Silver

Condition : New

Application : Flexibility of connects make cable & fixes connect precisely

Feature : Proper Working, Easy To Connect

Warranty : 1year

Country of Origin : India

...more

Copper U Clamps

Material : Copper

Surface Finishing : Polished

Shape : U Shape

Color : Copper colour

Usage : Pipe Fittings, Industrial Fitting

Specialities : Sturdiness, Proper Finish, Optimum Durability

Warranty : 1 Year

Country of Origin : India

...more

Copper Tapes

455 Per Kilogram

10 Kilogram (MOQ)

Type : Copper Foil Tape,Bare

Material : Copper

Thickness : 1.5mm,2-3mm,2 Mm To 6 Mm

Certification : ISI Certified,ISO 9001:2008 Certified

Application : Electrical Conductivity

Color : Brown,Dark-brown,Red-brown

Feature : 4 Times Stronger,Antistatic,Heat Resistant,High Voltage Resist,Holographic,Long Life,Waterproof

Design : Plain

Width : 1inch,Up To 75 Mm (for Earthling Purpose)

Packaging Type : Corrugated Box,Paper Box,Plastic Box

Country of Origin : India

Side : Single Sided

...more

Copper Sulphur Rods

450 Per Kilogram

Type : Copper Rods

Material : Copper, Pure Copper

Shape : Round, Square

Thickness : 10-20mm, 20-30mm, 30-40mm, 40-50mm, 50-60mm, 60-70mm, 70-80mm, 80-90mm, 90-100mm, 19 To 127mm

Certification : ISI Certified

Length : 1-1000mm, 1000-2000mm, 2000-3000mm, 3000-4000mm, 4000-5000mm

Grade : AISI, ASTM, BS, DIN, GB, JIS

Color : Brown, Light Brown

Feature : Corrosion Proof, Excellent Quality, Fine Finishing, High Strength, Perfect Shape

Finishing : Non Polished, Polished

Country of Origin : India

Textures : Solid

Brand Name : Jams copper

...more

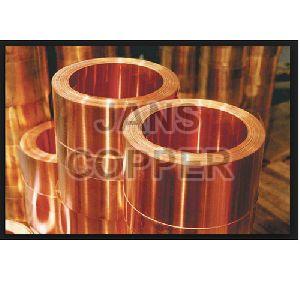

Copper Strips

455 Per Kilogram

Feature : Brightening Look, Durable, Low Consumption, Stable Performance

Material : Copper

Thickness : 0.5 mm to 10 mm

Width : 3 mm to 160 mm

Brand Name : Jams Copper

...more

Copper Square Bars

460 Per Kilogram

200 Kilogram (MOQ)

Application Areas: Bus Bars Transformer Connectors Earthing Protection in L.T. and H.T. Electrical Panels Power Transmission equipment Control Panels Thickness 1mm To 60mm Standard IS Brand Name Jans Copper Width 5mm to 350mm Edge Type Radius Corner Edge, Square Edge, Full Radius Edge Application Medical, Automotive Industries, Power Distribution, Telecommunication Edge Length Up to 6400mm (21`) Uses Bus Bars, Transformer Connectors, Power Transmission equipment, Control Panels Standard overall cutting tolerance 100mm Copper percentage 99.99 Additional Information Min. Order Quantity 100 Kilogram

Type : Copper Square Bar

Material : Copper

Shape : Square

Thickness : 4 Mm To 120mm

Application : Tunnel

Country of Origin : India

...more

Copper Section and Profile

485 Per Kilogram

Application Areas: Power generation-Hydro-generators Turbo-generators Wind-generators Nuclear-generators Electrical appliances Heat Sinks CPU Coolers

Material : Copper

...more

Copper Round Pipe

Material : Copper

Shape : Round

Color : Copper colour

Application : Construction, Industrial

Feature : Perfect Shape, High Strength, Fine Finishing, Excellent Quality

Warranty : 1Year

Country of Origin : India

...moreOpening Hours