air jet mill

350,000 - 4,000,000 Per piece

1 piece (MOQ)

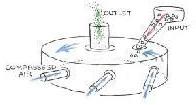

The Micronizer’s innovative design and fluid energy system enable numerous special-applica- tion possibilities for basic grinding, such as: Ceramic powders using wear-resistant ceramic liners Agricultural chemicals without attritional heat DN Pharma Micronizer meet a variety of material and output specifications. The typical feed size for Micronizer is 100 mesh or finer. The product size ranges from sub-micron to 44 microns. Capabilities range from 1/2 to 2000KG per hour. Micronizer may be operated using either compressed air, steam or inert gases.

PSI-18 Air Jet Mill

3 - 9,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Jet Mills

air jet mill

550,000 Per Set

1 Set(s) (MOQ)

The DN Pharma Micronizer is our response to meeting industry demands for constant improvement in processing technology. Utilizing a unique fluid energy grinding system to generate particle-on-particle impact, the Micronizer grinds and classifies powders to micron and sub-micron sizes in a single opera- tion, in a single grinding chamber.

Jet Mill

150,000 - 1,500,000 Per Piece

1 Piece(s) (MOQ)

jet mills are widely used in manufacturing of drugs and pharmaceutical, cosmetics, pigments, chemicals and food industry. working principle: jet mill grinds crystalline or friable material to low micron level. Generally finojet jet mill grinds material to 0.2-5micron particle size. Pulverisation takes place in the central chamber of jet mill as the process material is driven at near sonic velocity into the grinding chamber by convergent divergent nozzle. Cyclone is generated in the grinding chamber and particle to particle collisions takes place and hence material gets fine. No grinding media is involved so, process is pure without any contamination. feature of finojet jet mill: 1. No cross contamination 2. Narrow particle size distribution 3. Clean process 4. Simple assembly or dissembly 5. No heat is generated during the process hence suitable for heat sensitive product 6. Six different grinding chamber sizes available as per customer requirement. documentation to support fda validation: 1. Design qualification 2. Operational qualification 3. Installation qualification 4. Performance qualification 5. Site acceptance test

Jet Mills

Get Price Quote

The Air jet mills (fluid energy mills) are widely used in the manufacture of drugs and pharmaceuticals, organic and inorganic Chemicals, agro chemicals, pigments, food colour synthetic dyes, minerals, herbicides and pesticides, thermoplastics and other like heat sensitive , corrosive and abrasive mateials. The air jet mill employs compressed air, gas or high pressure superheated steam to achieve size reduction. These mills have no moving parts , thereby eliminating contamination due to contact with external grinding media. No additional heat is generated in grinding making it the ideal process to grind heat sensitive and fragile materials.

Jet Mill

Get Price Quote

Jet Mills are static equipment, without moving parts, that perform grinding through high-speed collision of particles.

air jet mill

Get Price Quote

air jet mill, Fluid Bed Dryer, Manual Capsule Filling Machine, Mass Mixer

Jet Mills

Get Price Quote

Jet Mills, air tray dryer, Agitated Cylindrical Vacuum Dryer

Jet Mill

Get Price Quote

Jet Mill, pharmaceutical machines, Planetary mixer, ROTOCONE VACUUM DRYER

Jet Mill

Get Price Quote

Jet Mill, Stator Winding Machine