oxygen lancing steel pipes

Calorised & Ceramic/ refractory Coated Oxygen Lance Pipe

10 Ton (MOQ)

We are offering calorised & ceramic/ refractory coated oxygen lance pipe. Ceramic coated pipe (ccp) is carbon steel pipe with multiple, thin layers of ceramic coating both exteriorly and interiorly. The ceramic coating is resistant to slag attack and extends the life of the pipe when it is immersed into molten metal or in high temperature atmospheres. The ccp applications include powder injections, tap-hole cleaning and opening nozzles in ladles, tundish and launders. Ccp was developed to increase the lance life beyond conventional black steel pipes. Ccp is also used to inject gas into the submerged electric furnaces. The pipe provides a much longer life in the high-temperature furnace environment than previously used stainless-steel pipes. Using ccp to inject gas in submerged electric furnaces reduces costs and downtime for smelter production. Characteristics of kandi lance pipes -> excellent refractoriness speedy de-carburisation for optimal metal oxygen interaction greater efficiency of reaction cost reduction in steel making some of the various uses of ccp include the following: cutting scrap, raising bath temperatures and decarburizing opening nozzles in tundish and ladles injecting carbon and other powders into the electric furnace and ladle opening the iron notch of a blast furnace injecting argon into ladles injecting argon and oxygen into the a.o.d. Furnace injecting flux for degassing in aluminum melting furnaces

...more

Burning Thermal Cutting Lance Pipe

1000 Piece(s) (MOQ)

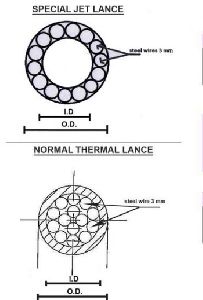

We are offering burning/ thermal cutting lance pipe. Burning lanceis the product developed, for the purpose increasing the heat quantity generated from the lance, by improving the cutting efficiency with the cutting core wires of several pieces up to several tens pieces built in the combustion steel pipe. The difficult-to-cut materials in gas cutting and mechanical cutting, i.e. Not only limited to iron and steel, the stainless steel, alloys such as brass, nonferrous metal, ceramic, etc. Can be simply and quickly cut off and bored without noise and vibration at the high temperature 3,600 deg f. It is optimum for cutting and boring special steel, cast steel, pig iron, slag and refractory. Heat source is not required for the equipment. standard sizes & length 12.7 mm o.d., 13.5 mm o.d., 17.0 mm o.d., 21.7 mm o.d., & 27.2 mm o.d. end finish: plain end, threaded and coupled. length : 2750mm, 3000mm andor as per customer�s requirement. applications defense & naval organisations non-ferrous & ferrous foundries and steel mills for cleaning up spills opening tap holes cutting refractory brick, skulls, and slag removing solidified material from vessels, ladles, and molds aluminum, copper, lead, zinc and nickel smelters ferro-alloy plants demolition paper mills - boiler tube and roll journal removal cement concrete removal - piling and slabs

...more

gas line pipes

Be first to Rate

Rate ThisOpening Hours