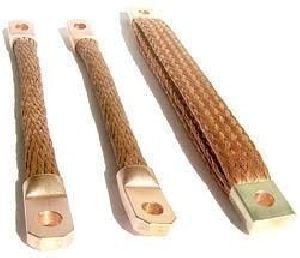

water cooled jumper cables

Kay Vybin water cooled jumpers or sub cables are flexible rope type secondary connectors, assembled with high conductivity terminals. They are sheathed with reinforced abrasion and oil resistant hose. Free water passage is insured by means of an open spring core progressing the entire length of the cable, thus permitting the cable to operate under conditions of acute bending without obstructing the water flow.

...more

Tool Changers

Features: Robot System Products Tool Changers are gives maximum flexibility to your robot. With low weight, Compact & robust design and high safety features, they continuously perform tool changing operations on a daily basis. The patented locking device TrueConnect™ has a unique design distributing the torque in all directions. It provides absolute positioning reliability and is especially forgiving on alignment when docking. The electrical pin connectors lined-up automatically to decrease wear and tear an increase lifespan. Advantages: Fast Docking < 20 mm docking stroke Forgiving locking device lines up automatically Robust designs for high torque applications Low maintenance 3D CAD models for Rob CAD systems.

...more

Swivels with Tool Changers

eatures: The swivels with Tool changer combine the best of both worlds to maximize your flexibility and productivity. Proven and Robust design ensures the highest possible reliability without limiting the robot’s performance or working range. These products are the obvious choice in applications that involve several welding guns or material handling tools and a lot of robot movement. The patented locking device TrueConnect™ has a unique design distributing the torque in all directions. It provides absolute positioning reliability and is especially forgiving on alignment when docking. The electrical pin connectors lined-up automatically to decrease wear and tear an increase lifespan. Advantages: No limit to axis 6 Air, Electrical signals, Field bus from axis 6 to the tool Also water, 200 A Weld power and Servo motor power & signal Integrated automatic tool changer makes a compact system

...more

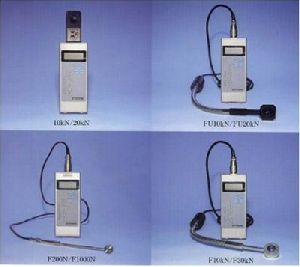

Secondary Cable Tester

Features: The model AMS-1070M measures an increase in DC resistance due to deterioration of the secondary cable or Kickless Cable and also detects an abnormality in the secondary circuit caused by insufficient bolting or oxidizing of the contact surface.

...more

robotic tip dresser

Descriptions : These dressers are mounted on a stand of a fixed height or of an adjustable height. They are made of : 1 electric motor which drives the cutter in rotation 1 dressing head which bears and drives the cutter 1 electric control unit 1 cutter rotation controller 1 swarf bin of adjustable height These dressers are designed to be used and to dialogue with a robot controller unit. Advantages Fast mounting and dismounting of the cutter on the dresser Easy to integrate Adjustable head every 90° Very compact dressing head, which makes it possible to dress all types of guns Adaptable and flexible product for each application Recommended pressure of the gun on the cutter 80 to 250 daN depending on the type of gun and electrodes Options Cutter rotation controller Gun current controller Gun force controller Optical « good dressing » controller Spring loaded head Swarf recuperation system

...more

Industrial Robot System

LEONI has completely redesigned the LSH guided robot Dresspack solution to be more reliable, compact and flexible, thus making the LSH 3 the most innovative Dresspack solution in the global market today. Its intelligent and extremely compact design minimize one of the most common causes of error for robot power supply – collision with interfering contours. This benefit in combination with extremely durable materials and proven components creates maximum clearance with a close-fitting Dresspack on the robot arm. The LSH 3‘s benefits include: Compact design: fewer interfering contours and lower risk of collision Significantly reduced volume, overall weight and length Maximum flexibility for Dresspack routing Compatibility with all LSH versions, without the need for any additional programming Compatible to corrugated and smooth yellow tube Umbilicals Significantly faster replacement of Dresspacks in comparison with earlier models No maintenance on the retraction element required All components are subjected to extensive field testing LSH 3 is available for new robots, regardless of size, manufacturer, type or application, as well as retrofits and upgrades for existing work cells. It can be mounted vertically, horizontally or upside down and each system can accommodate up to two Dresspacks with the widest range of nominal diameters. Optionally, a rotating pivot bearing can be mounted on the front end, which supports even the most extreme movement sequences while reducing stress on the Dresspack. The standard extension length of the LSH 3 is 350 mm. Mounting can take place on a customer-specific basis on axis 3, with or without adapter plate. Do you have special requirements? We would be glad to write up an individual offer for you. Your LSH 3 – your individual design Let us know if you would like your LSH 3 housing in a custom color or provided with your company logo. We can also provide the LSH 3 with custom extension lengths after prior arrangement.

...more

Robotic Combi Tip Dresser

Description : This dressing machine is mounted on a stand of a fixed height and made of: 1 tip dresser 1 automatic tip changer fully mechanic 1 electrode and chips bin system adjustable in height Advantages The 2 functions stay independent Easy to integrate Adaptable and flexible Vertical or horizontal mounting Light and compact Increased productivity Economic Reduced time and cost of integration Reduced cost of production Option: swarf carter Option: spring loaded system for gun without soft equalizing We can upgrade an existing tip dresser to a Combi changer/ tip dresser

...more

Robotic Calibration System

The challenge Continually securing the correct operating position for fixtures and robotic tools such as welding torches and milling tools. The solution The Advintec TCP tool calibration system calibrates the tool or fixture electronically in up to six dimensions. The robot program is automatically corrected by the measured variations and ensures that the tool always operates at the correct position. Advintec TCP is a high-precision calibration system that can be used for all robot types and most robotic tools, making it independent of specific manufacturers. Your benefit Correction takes place directly and automatically in the ongoing production process. Advantages at a glance Automatic absolute calculation of robotic tools and fixtures Auto-commissioning and ease of use Simplified Integration in the production line due to small footprint Robust sensor available in two sizes Multi-sensor-system (connection of additional sensors possible) Connection of the calibration system to the robot controller, i.e. the calibration procedure takes place in an evaluation unit and transfers correction values to the robot controller High process reliability No additional PC‘s required Logging of calibration data Data evaluation possible at all times Automatic correction of the trajectory due to wear and tear or tool-replacement 100 % quality assurance Reduction of costs Prevents the production of defective parts Reduces scrap and rework Short setup times

...more

P-Cap

The P-Cap delivers twice the tip life with four times the number of welds, all without tip dressing. The P-Cap uses a constant tip face geometry design for slow, consistent growth of the tip's welding surface. It eliminates the need for tip dressing, and produces high quality welds on bare and coated steels. The P-Caps are available in a wide variety of sizes and shapes and manufactured in both Nitrode® and Z-Trode® Materials. The P-Cap maintains a constant current density across the weld face under typical welding forces. It does require 90-degree to 90-degree face contact and the use of steppers to maximize life. P-Cap's physical properties Male and female versions Nitrode, Z-Trode and Cupal™ material All taper angles and a variety of weld face size

...more

Nitrode Composite

Nitrode Composite is a hybrid of the two most common resistant welding alloys - Glidcop® C15760 insert or core (GM Cupal material) and Zirconium C15000 jacket (Z-trode) that delivers a non-stick welding surface for ease of start up. Advantages Reduces the overall cost of welding Weld quality is maintained at a high level No adjustments to welding parameters required Can be dressed effectively using line side tip dressing

...more

Manual Tip Dresser

manual / dressing double face, gun closed: - works with same cutters as robot cutters. -competitive solution. pneumatic / dressing double face, gun closed: - works with same cutters as robot cutters. -competitive solution with pneumatic energy. pneumatic / dressing simple face, gun open: - works with same cutters as robot cutters. - competitive solution with pneumatic energy. - simple: no need of closing effort management for dressing and no need of specific program. - more safety for operators..

...more

Luvata Z-Trode

The Luvata Z-Trode® cap electrode is cold-formed from CDA Alloy 15000 zirconium copper. The combination of advanced copper metallurgy and our cold-forming technology gives you an electrode that outperforms conventional electrodes. Reduction or even elimination of weld Spatters No Sticking No Mushrooming Requires Less Energy In comparison to CuCrZr and CuCr alloys, Z-Trode requires lower current due to its higher electrical conductivity, when used on both sides of the weldment. This results in longer electrode life, more consistent welds and energy savings. Welder current settings can be reduced up to 20% from the conventional CuCrZr and CuCr settings, with no loss in weld integrity. Reduces Downtime Produces smooth Start-ups Most Cost effective electrode Z-Trode’s physical properties All Z-Trode electrodes are cold worked and most items are fully cold formed to ensure the maximum possible amount of cold work. Result; Mechanical properties equivalent to conventional CuCrZr and CuCr electrodes, but with better electrical conductivity. Hardness at ambient temperature: Minimum 65 HRB Conductivity: Minimum 85% IACS

...more

Kickless Cables

Little impedance and little reactance drop. High flexibility for good working efficiency. High resistance to repeating kicks and bending caused by electro-magnetic force induced by welding current and welding operation, and accordingly long life. Excellent cooling effect even in continued welding operation. Easy check, replacement, and maintenance. Covering of good pressure resistance, heat resistance, and wear resistance. The Kickless cable is consumable part and required to be inexpensive. Long cable life reduces cable cost per weld - the true measure of cable cost. We supply Kickless cables in two categories: Normal Hose Bellow Hose Normal Hose cables are recommended in normal applications where the twisting and bending of cables are minimum Bellow Hose cables are using a special hose which is more flexible and can be twisted 45 degrees on both direction which will reduce the operator fatigue substantially in areas where approach of welding guns are limited. All our export cables with bellow hoses and in domestic market, we supply bellow hose cables on special request.

Feature : Little impedance and little reactance drop.

...more

Hydraulic Weld Force Gauges

Features: Seven types of variations fitted to the weld force. Unit of gauge by the international standard N (Newton). Compact, light weight and easy handling. Insulated body to protect from weld current even by mistake. "Maximum Value Pointer" to hold at the maximum point. SP-241N has a flexible neck bendable to U-form. Carrying case is furnished for easy handling & storage. Outline: Model SP-231N is weld force gauge for measuring electrode force which is one of the important factors for spot welding. It is necessary to make precise control of electrode force for getting better result of welding. Sensor is closed and sealed hydraulic system and fabricated with insulation plate in order to prevent passage of electric current even when weld current is applied unexpectedly. High reliability of this gauge supports severe quality control.

...more

Digital Welding Meter

Features: Model SP-3110 is handy type welding current meter, which measures welding Current and weld time for spot welding, and digitally displays the result of Measurements, which can be simultaneously printed by the built-in printer.

...more

Digital Weld Force Gauges

Features: Measuring forces are digitally displayed successively. To ensure accuracy, measured value is displayed per every half second based on the average value of sampling in 64times/sec. "HOLD" function allows any measured value to hold on in the display. The unit can memorize maximum load during measurement and its value is displayed after measurement. Auto-Zero reset function for easy operation without making zero adjustment. Dry batteries (UM-3x2) are used for power source which support easy handling. Auto-power off function for saving power consumption. Alert of battery replacement is indicated in the display. Outline: The model SP-255 is a handy type digital welding force gauge which can measure weld force applied between electrodes that is one of the three important conditions for the spot welding. The model measures the force applied and displays data on LCD by

...more

Cutters and Blades

Symmetrical Blades: Perfect guidance of the tips. No vibration during dressing. Diameter of the lens guaranteed circular Tol+-0,1mm. Quality improved. Chip thickness controlled by AMDP design, not by clamping force of the welding gun. Cost of the chips improved. Outlet bowl chips: - No hole through cutter: No jamming. - Ejection of the chip without air blower. Less investment. Less running costs. Keep welding line capacity. Longest Life: Cutter : 60,000 Dressing Cycles Set of Blades: 15,000 Dressing Cycles Customer is already using competitor’s equipment? ?! AMDP has the solution! AMDP also offers AMDP Cutters for Competitor’s Tip dressers

...more

Copper Shanks and Holders

Being a pioneer in manufacturing Resistance Welding Cables in India & a market leader for these cables, Kay Vybin has decided to serve their customers with more range of weld shop consumables specially copper consumables like cap tips, electrodes, shanks, adaptors etc as per customer’s requirement. Having a well-equipped in house manufacturing facilities for these copper items as well as the production & technical expertise, Kay Vybin has already manufactured more than 100 types of different shanks & adaptors & they are successfully running at our esteemed customers plants like FORD (Sanand), Tata Motor vendors (Pune), etc.

...more

Air Cooled Cables

To meet the connector needs in resistance welding Kay Vybin offers a broad variety of secondary connectors. Each cable or secondary shunt is designed and built to perform with maximum efficiency and economy in its intended application. Kay Vybin air cooled jumpers are required to electrically connect distant points which move in relation to each other. Such as : (a) The movable gun-arm of certain types of welding guns to KayVybin cable. (b) On multiple spot welding machines. KAY VYBIN air-cooled jumpers are extra-flexible rope type secondary conductors, with connectors, swage-formed on each end for maximum flexibility and cooling. The standard terminal width is 32 mm. if a wide terminal is required, please specify when ordering.

...more

Cable Repairing service

KAY VYBIN CORPORATION, offers a fine, complete repair service of cables or for outer cover replacement where this is the only work necessary. Repair: Cables returned for repair can be accepted only when transportation charges are PRE-PAID. Returned cables will be partially dis-assembled for inspection. KAY VYBIN performs an inspection report on all returned cables. The customer is then notified as to the repair or replacement charges and work to be done. If the customer decides not to continue with the work, the cable(s) will not be re-assembled or returned. We do not repair Air-Cooled jumper cables or Laminated Shunts. Rebuilding or Replacement: If our inspection indicates returned cables are not suitable for a "recover" - meaning all or part of the nonferrous metals are unable to be reused, the nonferrous metals will be weighed and a credit based on current recycle value of nonferrous metals shall be provided to you. **Pricing will be provided for all cables based on our ability to either simply recover them with new hose and bands or **Pricing will be provided for a rebuild meaning pricing will factor in the nonferrous metals (terminal ends and braided rope) that needs to be replaced. Note: A rebuild is essentially and for the most part a new cable and pricing will be closer to that of a new cable; however, we do provide, as stated, credits toward recyclable materials.

...moreBe first to Rate

Rate ThisOpening Hours