Web Dryers and Sheet Ovens

KERONE offers energy efficient custom infrared ovens used for stationary batch processes. Some applications include mould pre-heating, glue activating, drying, fusing, annealing, and curing. Product temperatures of 150 degrees F to 600 degrees F are common for Infrared Batch Ovens, while higher temperatures can be achieved. A reliable custom control panel can be supplied for the oven with optional timers, precise solid state controllers, and sensors as required. We also offer custom carts or racks to transfer or hold your products. All batch ovens are completely factory assembled, set up and tested prior to shipment to assure a simple trouble free start up.

...more

Web Dryer

We have gained expertise in manufacturing and export of high velocity web dryers, and available in different widths, lengths, heating areas, motor power and production capacities. These dryers are provided with a series of upper & lower air bars for floatingly suspending a running web as web moves through dryer. They also have a specifically molded chain, flexible & fixed baffle, supporting roller to avoid scrub and color pollution.

...more

Web Coating Systems

Web coating is the continuous process of applying a coating material – whether its of a solid or liquid substance – onto a particular substrate. Web coating is able to apply, coating over a extensive variety of numerous different kinds of substrates, such as plastic, paper, fabric, metal etc. Web coaters have became quite useful and preferable choice of industry due to its economical approach, high efficiency, cost effectiveness and high production rate. Web Coating Dies have many advantages over traditional coating methods such as roll coating. These types of machine also use less material, have better gauge control, and can apply multi-layer and pattern coatings. Exacting tolerances of up to 75 nanometers are available to complement the application and process specifications.

...more

Water Still Distillation Unit

All Glass water still All glass water distillation is a unique & intelligent water distillation unit.The heating element is ceramic bobbin heater with Nichrome heating wire. The distillates of unit have very low conductivity(less than 1 mho).The company has two model viz, 1.5lt/hr distillation water output for continuous run & 4.5 liters/hr capacity. Added Feature : The unit has unique feature for automatic water level maintain by solid -state device.It gives audible alarm when the water level is sufficient.Both the unit comes in 3phase/single phase electrical poer supply model.The whole unit of the system is made of stainless steel. The unit is totally hassle & maintenance free with intelligent & user Friendly. Water Still Condenser Opening type : These electrically operated water stills have been scientifically designed to ensure economy in operation and beyond occasional cleaning they do not require any special attention. Complete body and condenser tube is made of stainless steel .A triple vapor baffles provided to avoid splashing of water into delivery tube.The lid is automatically sealed by recess in the head of the still into which the flange of the lid rests.The minimizes the loss of steam.The water supplied to the still through the constant level arrangement also serves to condense the steam in the condenser. The condenser tube can be dismantled without any difficulty, by removing the wing nuts which hold the end condenser jacket together.Removing the lid exposes the evaporating vessel. The still is fitted with immersion type elements,which are capable of displacing the connectors, if the still runs dry. The still is provided with provided with a bucket(to be fixed on a wall) on which it can rest.

...more

Water Heater

Several industrial processes require hot water. Some also require water heated to steam. Our industrial water heaters are well- known in industrial circles for the high quality of the raw material which we use and for their efficiency, reliability, long, trouble-free service and cost effectiveness. These heaters have also been installed in several large hotels, restaurants and resorts. Additionally, they are used healthcare, educational, multi-family dwelling and similar establishments. Large laundries and the food processing industry are among our customers.

...more

Water Bath Thermostatic

Our water baths are widely used for the day to day bacteriological and laboratory applications requiring incubation as well as general tests and procedures in variety of research and testing laboratories.Apart from that these water baths have a variety of usages in tissue culture application,enzyme reaction studies,growth observation studies,Fermentation analysis and various other general and specialized application in various laboratories. We specialize in both standard and customized models, specifically designed to meet the challenging demands of various scientists for individual and specialized research applications. Over a short period of time Weiber brand have been established as reliable exporters of water bath in India, catering to the vast marketing in South East Asia ,Middle East ,Africa and Europe. Apart from that we are supplying our water in India ,catering to a variety of customers ranging from defense installations,Research /laboratories ,Education Institutes and various R&D Laboratories of leading national and multinational companies. Construction details water bath : Our water baths are double walled convection heated units. Outer body of our baths are constructed out of thick PCRC steel ,duly pre-treated with primers for rust proofing and painted with air drying paint/stove/powder coating .The inside chamber of the unit is made of heavy gauge stainless steel sheet of grade ss-304.The unit is provided with providing with top opening cover, made of stainless steel with steel concentric rings.The units is provided with one stainless steel rack to hold six twelve flasks. Heating: Indirect Heating is provided in our water ,comprising of air heater made of high grade kanthal A-1 wires of suitable wattage.The temperature is evenly distributed throughout the chamber through nature water convection mechanism,ensuring a very good temperature sensitivity. Temperature Range: Temperature range of our standard water bath models are 5oc above ambient to 90oc.However we have the capacity to modify the same to suit the individual specialized requirements of our customers. Temperature Sensitivity: Inside our water bath is controlled with a sensitivity of-+0.5oc or better.(with PID controller) Front Panel Front Panel of our water companies of on/off switches heating and mains indicators lamps and temperature controller.

...more

VLE Fan Heater

Unit heaters – integrated units of heating coil and fan – are primarily designed for heating of large rooms by means of hot air. This heating method has a number of advantages as far as space, operation and economy are concerned. Our VLE Fan Heater is a low cost, heavy duty electric heater, suitable for places where the insulation is moderate, i.e. not of industrial standards. This heater is used in homes, garages, workshops, storerooms and other places where some level of heating may be required, but the situation does not permit use of a high level of insulation. The heater gives good performance even in places like ships, and in warehouses and large production floors, where the environment could have an aggressive impact. Our heater gives long, trouble-free service. It is easy to install on walls and ceilings. The built-in thermostat controls the temperature.

...more

Vertical Blender machine

Kerone are engaged in manufacturing and supplying a wide assortment of Vertical Blender. We can also custom design a system for your needs. The offered range is manufactured using premium quality raw material and advanced technology in compliance with the international standards. Additionally, our offered product is tested on various parameters under the guidance of our skilled professionals. These blenders are available in varied sizes as per the variegated needs of clients. Our organization is highly involve in providing a wide spectrum of Vertical Blender. These are developed from finest quality raw materials, which ensures high durability at its user ends. Vertical Blender Mixers are premium designed alternative for applications that pare sensitively in vertical positions. This high-quality blender is available in 6-, 8-, 10-, 13- and 16-ton capacities. Features of Vertical Blender Homogeneous Blending in short Time Blending With High RPM This blending machine is specially designed to reduce operation cost and time Long working life User friendly design Less Electrical Power Required Blending With Vertical Auger Less Ground Space Required Feed and Unloading at Ground Operating Level Substitute for Cone, Vertical cone Mixture Liquid Addition Arrangement Advantages Vertical Blender 1. Gentle blending action is ideal for friable or shear sensitive materials. 2. One blender can be used for a wide range of batch sizes, ranging from as small as 10% of the rated capacity. 3. Nearly 100% of the blended materials are discharged through the bottom valve after completion of the blend cycle. 4. Use nearly 50% less power per unit being blended. 5. Less floor-space and are ideally suited to multi-story facilities.

...more

Vertical Autoclave

Our vertical autoclave are widely used for the day to day sterilization procedures and in various laboratory applications.We specialize in both standard and customized models, specifically designed to meet the challenging demands of various scientists for individual and specialized research applications. Apart from that we are supplying our economy autoclave in India catering to variety of customers ranging from Defense Installations,Research Laboratories and Educational Institutes and various R&D laboratories of leading national and multinational companies. Construction : Our vertical autoclave are double walled units.Outer of our autoclave is constructed out of thick PCRC sheet duly pre-treated with primers and rust proofing and painted with lasting stove enamel or elegantly powder coated..The inner chamber is made of heavy gauge stainless steel of ss 304 grade .Our autoclaves are air insulated from inside,however we may incorporate mineral glass wool insulation if the customer desires so. The strong lid constructed out of thick steel plate which is lined with stainless steel sheet of ss-304 grade has a locking arrangement ,which ensures an easy and smppth opening and closing operation for all autoclaves. Our vertical enclaves are ideally suited for hospitals and research labs where safety is the priority of the user since it is equipped with a double safety steam releases valve.At the same time we test all our protection from any unfortunate incident.All our vertical autoclave are supplied complete with pressure gauge,pressure release valve and stainless steel basket as a standard feature. Heating : The heating process in our vertical is autoclave is done through specially water heater of suitable wattage to ensure optimum sterilization time in every sterilization cycle. Working Temperature : Asper the international standards and guidelines our vertical autoclave have a working temperature of 121 o cHowever for specific requirement our be upgraded to be used for up to 134 o c Working Pressure : Working pressure for our standard model vertical autoclave is 15 psi,however this can be upgraded to be used for higher pressure of up to 30 psi.. Pressure Range : The normal pressure range of our autoclave is 5 psi to 20 psi Pressure Control : The pressure inside our vertical autoclave can be controlled throughout a semi automatic electro mechanical device called piezostat,which controls the pressure inside the chamber and cuts of the current from the heater whenever the pressure exceeds the set pressure valve of the autoclave, thus making it very safe and energy efficient.

...more

Vacuum Infrared Heating System

Kerone manufactures a full range of gas fired, high and low intensity infrared space heating equipment under vacuum for the commercial, industrial, agricultural, residential and hospitality markets sold internationally. With Superior Radiant Products, customers can expect the highest quality of products developed, designed, and improved since 1995. Application of this tool include: Custom engineered to precisely fit your building heat requirements. Vacuum vented for maximum safety and operating efficiency. Burner rates from 60,000 to 250,000 BTU/H can fill any heating need. HUp to 1.2 million b on a single vacuum pump with single building penetration Reflectors of superior design and performance with side, bottom and tilted shield options.Run indicator light. Couplings that outperform all others. Burner housing with no loose service doors. Filters are easily changed even with outside combustion air fitted. Vacuum pumps are corrosion resistant, heavy duty construction with several sizes available to best match the system. Decorative grills can be installed as an option.

...more

Umbrella IR Dryer

Kerone Umbrella Infrared dryer introduces a new revolution in outdoor heating. IR Umbrella dryer runs on regular household electric current. We offers convenience with simple touch of On/Off. Infrared ray sensors detect umbrellas and activate dryer. We are manufacturing and devloped from galvanized steel and rotates for easy loading. This clothesline has 12 lines and provides 165 feet of drying space. If you do'nt wish to have it as a permanent structure, you can fold down this compact galvanized steel clothes pole and store it until its next use.

...more

Uv Cabinet

Cabinet for Chromatographic analysis by ultra violet fluorescence. Fluorescence analysis under laboratory lighting condition.Fast, simple and convenient operation with independent controls at tops. Long wave and short lamps plus white light provides three means of locating and identifying components. This chromatogram viewing cabinet combines both long and short wave ultra violet and also white light in a compact table-top unit.This self-contained unit is designed for easy viewing and making of chromatograms and also for general florescence studies.Chromatograms can be viewed with 3600-4000 A Long wave or 2500Ao short wave ultra violet or with white light. The ultra violet lights can also blew used in combination if desired. Black curt ion on the front ensures darkness and brilliant florescence inside the cabinet,at the same time enabling the operator to adjust the sample and lights easily or making. Construction: Study all metal construction and provided with two handles at the sides for transportation.Switches and fitted at the top for easy operation. Application : Long wave : Fluorescing spots on chromatagrams can locate compounds like dyestuffs,vanillin's flavones,alkaloids etc. Short wave : Detects Compounds,such as barbiturates purine and pyrimidine derivatives ,PHT-aminoacids,DNP -amino acids and steroids. In detection of traces of minerals,study of old inspections.

...more

Twin Tube Short Wave Infrared Module

This is made up of 8-shape high-purity clear quartz twin tube, each tube has Heating Coil of Tungsten material which runs in U shape in the tube which is filled with halogen gas. Power Density up to 150kw/m2 is achieved. Heating up and cooling down time is approximately one second. These heaters are available with gold reflector and without reflector. Reflector is in the form of gold coating on outer rear side of the tube. Due to reflector heat loss from backside is prevented and thus power saving is achieved. This also results in making surrounding work area cooler. This also increases the efficiency and directionality of the heater. There are two standard sizes 11 mm x 23 mm and 15 mm x 32 mm in cross section. Maximum length available is 2000 mm.

...more

twin tube medium wave infrared heater

Our Twin Tube MW IR Heater is made up of 8-shape high-purity clear quartz twin tube, with each tube having Ni-Chrome heating coil that runs in U Shape in the tube. Features Heating up and cooling down time is approximately 50 secs. Available with gold reflector and without reflector. The outer rear side of the tube of the reflector has the gold coating. Heat loss from backside is prevented by the reflector, thereby power is saved. Results in making surrounding work area cooler. Increases the efficiency and directionality of the heater. Specifications: Standard sizes (in cross section): 11 mm x 23 mm & 15 mm x 32 mm. Maximum length: 200 mm. Power density: 60 KW / m2 can be achieved. Paint Baking

...more

tunnel ovens

These ovens have been designed for use with a wide range of existing conveyor systems. We provide electric gas and steam heated units with operating temperatures from 650C to 6500C. Tunnel ovens are designed to include support points for your conveyor system. Adjustable silhouette dampers are provided on the oven end openings to minimize heat loss. Each Oven is designed for the specific application and can include multiple heat zones and a cooling zone. Units can be provided in sections for easy installation and mating with existing conveyor system.

...more

Tunnel Dryer

Tunnel Dryer offered provides for high heating efficiency and successfully support the process demands of low and high temperature drying. Further, the automatic operation support provided by these tunnel dryers as well as requirement of minimal human intervention through optional support of SCADA system also makes these highly preferred by the customers. Some of its features include works on counter-current drying principle for efficient and consistent performance, comes with advanced designed drying modules developed using mild steel for consistent performance, advanced air inlet-outlet ducting support, can be provided with auto door support for minimized manual interference among others. Other Details Durable construction Easy operation and minimal maintenance High level of safety in operation, thus greater reliability Optional recirculation system to improve overall thermal efficiency Fully automatic burner control and temperature control Units are available from capacities of 20,000 Kcal/hr to 30,00,000 Application Tunnel dryers are useful for drying large quantity of Organic wastes, coconuts, copra, fruits, vegetables, sliced onions, garlic, Raw cashew, cashew nuts, ground nuts Ceramic Fiber Papers, Ceramic Fiber Boards Molded Paper Products Rayon Staple, Cotton linters Noodles, Food products, etc..

...more

Tunnel and Clam Shell Ovens

KERONE offers energy efficient electric infrared tunnel and clam shell ovens. This style of oven is similar to web dryers in that the product is normally spool to spool or continuously run unsupported through the oven. Some applications include heat shrinking, curing and drying for inks and coatings on wire, cable, and tubing; preheating composite lumber prior to embossing; post heat extrusions/pultrusions, and curing paint on sheet metal coils. Tunnel and clam shell ovens are custom built with removable side panels or hinged housings for easy product threading and maintenance. ovens are designed to be installed quickly, with a minimum of field wiring or preparation required. They are completely factory assembled, set up and tested prior to shipment to assure a simple trouble free start up. For the oven heat source, offers a variety of electric infrared heaters, each with their own heating advantages and unique characteristics. All heaters are completely manufactured at assuring you the highest quality, proper use, and best support. Our popular series Infraround heater is often used for clam shell configurations. The electric IR heaters are proven to be highly efficient and environmentally friendly to save you energy dollars and eliminate hazard and emission issues. A reliable custom control panel can be supplied for the oven with precise solid state controllers, sensors, as required for a stand alone or integrated system. We can also build custom stands, rollers, or attachments to help support your products.

...more

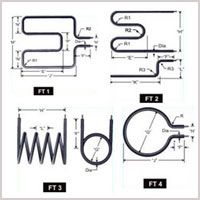

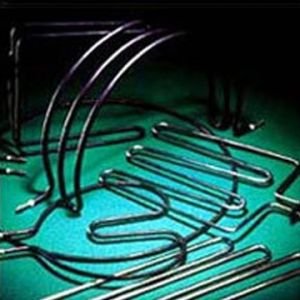

Tubular Heating Elements

We are a noted name engaged in trading and exporting a wide range of Tubular heating. Kerone are the most versatile and the best suited solutions to a large number of applications. Tubular heating elements are factory-configured to almost any shape or size as per application demanded or their configuration is customized according to customers specifications. These heating elements have a strong outer sheath to protect the heater from physical stress and uses high quality alloys to allow efficient heat transfer from resistance coil to your heating medium. Typically using steel, incoloy, titanium alloys, stainless steel, inconel, tubular elements are often known as the foundation of all heating elements.

...more

Tubular Heaters

Tubular (sealed element) is a fine coil of Nickel chrome wire in an insulating binder (MgO, alumina powder), sealed inside a tube made of stainless steel or brass. These can be a straight rods (as in toaster ovens) or curved to fit in a smaller space (such as in electric stoves, ovens, and coffee makers). Tubular heaters during recent years are widely accepted as a mode of heating due to their flexibility with which these can be formed into any shapes and sizes depending on the applications. Due to their versatility, flexibility and relative insensitivity to mechanical damage, the tubular heaters have often provided ideal solution to difficult problems encountered in heating. Our range of tubular heaters are designed and manufactured with state-of-the-art technology which are very compact in construction, easy and economical in operation and consume less electricity. We offer tubular heaters that are practically hassle-free and maintenance free. Our tubular heaters are known for their reliability, durability and higher efficiency. We ensure that our tubular heaters are manufactured for optimum performance. Our tubular heaters are manufactured using best quality raw materials. We offer these tubular heaters at very economical industrial prices. We also customize these tubular heaters as per our clients' requirements and specifications

...more

Tray Dryers

Tray Dryer is used for the best drying results in conventional process.It is a double walled cabinet with one or two doors.The gap between two walls is filled with high density fibre glass wool insulation material to avoid heat transfer.Door are provided with gaskets.Stainless steel trays are placed are placed on the movable trolleys. Dynamically balanced axial flow type blower fans are provided air circulation in the drying chamber during process.Machine is provided with control panel board with process timer.Digital temperature controller cum indicator etc. Capacity 6,12,24,48,96 192 trays. Satndard & GMP models anailable SS 304/SS316/MS internal & externals. Stainless steel tray in S.S. 304/S.S. 316 Quality. SALIENT FEATURES : All stainless steel 304/316/316L construction for pharmaceutical application or external mild steel with SS internal parts. Electric /Steam / Thermic Fluid heating Control panel board with process timer.(Circular chart recorder can be provided on demand at extra cost.) Sturdy trolleys with castor wheels. Air filter at inlet. (Hepe filter can be provided on demand a extra cost). Easy accessibility of impellers for cleaning. The exhaust duct,blower & air inlet filters can be custom built to keep out the production area with suitable ducting.

...more

Thermocouple Ceramic Infrared Heaters

CIH with thermocouple made of Nicrome and Nickle (NiCr-Ni) alloy. Thermocouple heater is embedded in immediate vicinity to the heating coil. The Thermocouple Heater is then connected with temperature controller to achieve desired temperature. Advantages With these building a temperature control system is very easy. The operating temperature is reached quickly and remains constant. This is not affected by mains voltage fluctuations or airflow. The temperature of elements remain constant even in case of no-load operation.

...more

Surface Heating Treatments System

The concept of surface heating very popular in industrial applications such as textile, ceramic, wood, metal, paper & printing, processed food and FMCG, the output required to be dried from the outer skin to harden it from surface or crust. Most common application of surface heating is making of bread where outer crust of bread is harden but the inner part is kept comparatively soft, even in paper printing it’s required to dry the printing ink by heating the surface of material on which printing has been done. The conventional heating system when used for the surface drying, it requires huge setup and requires high energy source, conventional surface heating system heats the surface of material by utilizing hot air or steam as medium to transfer the heat. Hence it increases the surrounding temperature, also result in hug loss of energy and power. To achieve the better result in less cost, by maintaining ambient temperature the conventional heating systems are replace by advanced Infrared heating system. Infrared surface heaters utilizes the property of infrared radiation to generate the heat on the surface of material itself, since the infrared surface heaters uses infrared radiation and this infrared rays are not absorbed by the air this results in maintaining ambient temperature. Heat is generated on the surface hence the rate heating is more, this result is shorter time required for the drying of material. Infrared dryers (IR dryers) hinder the formation of a skin or blisters on the surface and accelerate the drying of the paint, this results in a shining surface quality. KERONE is one of the leading names in designing and manufacturing surface heating system for various industrial needs since last 40 year we have helped various industries to achieve desired result from surface heating system from conventional to new age Infrared heaters. We understand the technicality and process of industrial requirement and accordingly design infrared (IR) surface heaters. Advantages of Surface Heating treatment Systems: IR heating systems are faster heating system, results in saving of time. Instant heating of the material, hence no warm up time. Environmental friendly and green heating solution, no carbon emission. 100% energy utilization, Heats only desired spot of material. Better floor utilization index, as compact in size. No Temperature loss in surrounding, ambient workplace.

...more

Surface Heating System Gas

Gas Infrared heat is well thought-out for the easy and economical method of heating or drying of the material under the process. Gas Infrared heaters uses the gas for firing of the infrared radiator which radiates the infrared electromagnetic waves, the infrared waves collides with the surface of the material which caused the surface of material to start getting warm hence its also know as Surface infrared heating system. As infrared heating system / surface infrared heating system radiates the waves from the surface and heats the surface the total process of heating becomes very fast and efficient, also environment friendly. Every oven is designed only after by carefully studying the client's specific process requirement to develop the heating system that will best fit for the application requirement. We also hold our expertise in designing of conveyorised gas infrared (IR) ovens that uses the efficient gas firing system designed cautiously by the KERONE. The conveyorised gas fired infrared (IR) ovens are manufactured after scrutinizing the speed, heating and cooling zone requirements. Conveyorised gas fired infrared (IR) ovens manufactured are having heating zone control and conveyor speed control mechanism. Applications : Infrared heating systems find most common application in Curing of coatings Plastic shrinking FPlastic heating prior to forming Plastic welding Glass & metal heat treating Warming suckling animals or captive animals in zoos or veterinary clinics

...more

Super High Temperature Black Infrared Heaters

Super high temperature heaters were developed to increase the previous maximum possible surface rating of ceramic panel radiators from 64 kw/m2 to 77 kw/m2. This radiators, produced using the hollow casting ceramic process, are filled with thermal insulation material and have a special black gaze and a gold-plated back. At an operating temperature of 900°c, over 75% of the electrical energy supplied is transferred to the material to be heated as medium to long-wave IR radiation. This series radiators are therefore particularly suitable for use in plant construction in which special solution have to be drawn up for the customer's specific needs and for applications requiring high outputs. The four designs cover the power range from 300 W to 1200 W and have customary market dimensions. Existing IR equipment can therefore be retrofitted with this series radiators.

...moreBe first to Rate

Rate ThisOpening Hours