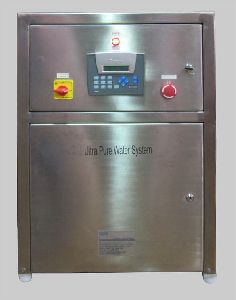

Ultra Pure Water Systems

Komal manufactures complete system to meet very special application for the Research lab and electronic industries. Water produced will meet the standards like CAP, ASTM, USP, NSST etc. Standard units having flowrate of 5/10/30 lit/hr. is readily available. Units are microprocessor based controlled with replaceable cartridges. System comprises of Pre-treatment ,Reverse Osmosis Membranes, Organics removal ion exchange Resins, Nuclear grade resins to get the water of 18 Mohm resistivity. Various options are available for post treatment like ultrafiltration, 0.2 micron filter of TOC Reduction UV Our latest inclusion is Electrodeionisation for pre-treatment to get the water of 12-14 Mohm quality. Same water can be use to get 18 Mohm water for a wide range of applications. Advantages OF Komal Water Systems: Extremely low toc value. Cost effective. Specific reistance of 18.2 Mohm / cm Low bacterial count Arious options to suit your quality requirment Toc reduction uv for final treatment Users friendly microprocesor based controller. Can be connected to municipal water. Auto flushing and cleaning of membranes

...more

Purified water and WFI storage tanks

After the purification of PW or HPW, engineering of the customer-specific storage and distribution system takes place, so product water can be delivered to each point of use in the sterile distribution system without recontamination. Here to we consider the customer's specific conditions and produce an individually engineered design. Following are the features of the KOMAL PW storage tank: 316L SS storage tank for PW and HPW Internally electropolised. Externally mirror / matt finish Jacketed hydrophobic 0.2 micron Vent Filter Level transmitters Compound Pressure gauge Pressure release valve Spray ball STEAMtrap assembly Inlet STEAM control valve

...more

Purified water and WFI Distribution Systems

Once the PW is stored in a tank, it now needs to be distributed to each and every point of use in the factory without recontamination. The entire distribution system is be made of 316L stainless steel tubes, the surface quality from Ra

...more

pure steam generator

The pure steam generation system consists of two columns – Evaporator and Separator. The Evaporator is a shell and tube type of heat exchanger. The driving force i.e. plant steam heats the feed water in the tube side of the evaporator to generate vapour. The generated vapour enters the Separator column. The separator column uses a triple punch separation technique for particle entrainment and separation of impurities such as droplets and pyrogenic material. The first punch is offered by the multi- directional baffle, which makes the vapour traverse a torturous path. In the second stage, the steam passes through a cyclone type centrifugal separator. The final blow is delivered by a Demister pad to ensure pyrogen free, dry and saturated steam. Features Komals Pure Steam Generator is a packaged skid mounted unit incorporating all necessary controls and functions to produce Pure steam as per latest IP/BP/USP standards. Plants are available from 50 kgs/hr to 2000 Kgs/hr, These generators are basically used for Sterilization of vessels, Sterilisation of Distribution systems, Autoclave, reactors and also humidification of sterile area Full-Automatic PLC based Control Panel System with auto sanitization and printing facility. First column equipped with Double tube sheet as a provision to avoid boiler steam mixing with Purified water. All Contacts parts are SS316L with internally electropolishing < 0.5Ra Complete documentation to meet and exceed international audit requirements. The piping system is orbital welded and qualified using videoscopy procedure.

...more

Pretreatment Water Systems

Strong, Long Lasting KOMAL WATER Pretreatment Systems- engineered for the most demanding industrial, commercial and residential needs. Komal offers line of Pretreatment equipments designed to accompany our RO and EDI systems Filtration systems can be designed to be operated in Automatic or Manual mode. These systems are configured in series or parallel depending on quality or flow-rate requirements.

...more

Multi Column Distillation Plant

The WFI Still work on the distillation principle. The first column is heated by the external Plant steam. The generated vapor by the feed water rises up the column where it is subjected to the entrainment separation system. Multidirectional baffles deliver the first punch. The steam generated from the first column is made to pass a torturous path through multidirectional baffles. Here the pyrogen particles and droplets separate and are guided to the end of the column. A centrifugal type cyclone separator high up in the column delivers the second punch. Here the vapor is guided through a narrow circular channel where it begins to rotate. The vapor flow subjects the pyrogenic impurities and droplets to a high centrifugal force thereby dislodging them from the vapor steam. The distillation units are connected in series into a multiple effect system and external energy is required only at the first column. The steam generated in each column is supplied to the subsequent column. The generated steam vapor of the last column and the almost condensed steam distillate (2nd column onward) is led to the over head cooling heat exchanger, where it is cooled by the cooling water & incoming feed water to generate WFI. Features Komal’s Multi-Column Distillation Plants (MCDP) are designed to produce pyrogen/endotoxin free water conforming to IP/BP/EP/USP standard. These individual columns are designed , constructed and tested per the American Society of Mechanical Engineers (ASME, Section VIII, Division 1- Unfired Pressure Vessels) since they operate at pressures as high as 6 to 10 bar All Evaporator (columns) sheets and tubes as well as all surfaces in contact with Pure Steam or distillate are constructed of 316L stainless steel with inside electropolish and Teflon gaskets. All tubes joints are Orbital welded and qualified with videoscopy. Full-Automatic PLC based Control Panel System with auto sanitization and printing facility. First column equipped with Double tube sheet as a provision to avoid boiler steam mixing with Purified water. Komals WFI-Combo design optimizes the Control Panel by combining the panel for WFI Generation and Distribution system Plants are available from 50 Liters/hour to 10000 Liters/hour. Complete documentation to meet and exceed international audit requirements.

...more

demineralisation systems

Advantages Of The Komal Demineraliser The new KOMAL demineraliser …gives you chemically pure water – instantly and continuously, year after year. … has durable resins with the highest demineralising capacity. … Uses resins of the highest quality. … comes with the conventional conductivity meter. … is extremely easy to operate and need practically no attention after it is installed. … can be connected directly to any water supply main. … is delivered promptly. … is available in a wide range of flow – rates. Wide Range Of Application Chemically pure, demineralised water is a more efficient substitute for distilled water in a wide range of applications: Pharmaceuticals : Battery manufacturing Cosmetic : High Pressure Boiler Surface Cleaning : Hospitals Chemicals : Laboratory Electronics : Research Technology Paints : Distilleries Komal DM Configurations KOMAL is offering water Demineraliser in four different configurations. FPK Series – FRP Construction FPK Series' pressure vessels are manufactured using composite Fiber Glass. Vessels are 60% lighter than steel vessels. All the vessels are vigorously tested at 10 bar pressure. They are all moulded and have better impact strength and are lighter in weight.

...more

purified water generation systems

Each plant for the production of purified water is custom made, whether its capacity is 100 lh or over 25 m3 h. Every plant is designed with the customer and all the design parameters in minute details and with the same passion and dedication towards building an effective, safe and reliable system. After all each customer has a different system requirement: An SME engaging in contact manufacture has need which differs from an international conglomerate. Thus no plant is entirely like any other. ALL KOMAL PW basic systems meet EP, USP and guidelines and ensure the production process, product quality and profitability. The GMP-compliant confirms to FDA and ISPE requirements.

...more

juice processing plant

We are leading supplier of huge range of Juice Processing Plant

...more

Bottled Water Manufacturing Systems

We deals in manufacturing of wide range of Bottled Water Manufacturing Systems

...more

Soda / Soft Drink Plant

We are well known for exporting of wide variety of Soda Soft Drink Plant

...more

Komal Reverse Osmosis System

The unique features of komal reverse osmosis (ro) system allow you to produce high quality water consistently for a variety of applications. With their compact designs, simple operation and low maintenance, komal system are perfect for your use.

...more

Ozone Generators

KOMAL manufactures a Corona Discharge Ozone Generator and Ozone application Engineering Including dissolution column, air preparation unit and Ozone destruction. 'OZ1 series of Ozonator Generator operate exclusively on oxygen feed gas, Eliminating the need of Air preparation unit. For the smaller requirement of ozone 'OZ' Series Ozone Generator is very efficient, reliable and very cost - effective.

...more

Ozone Production

Ozone producing electrodes are of the corona discharge type, having a 316 stainless steel tubular outer shell, with an internal cylindrical dielectric assembly. The dielectric has a conductive material that is applied to the inner surface and is connected to the high voltage, low or medium frequency power supply with the s.s. Tubular outer shell acting as the ground between the s.s. Tubular outer shell and the dielectric assembly is an air gap ozone" corona" discharge gap. The oxygen enriched feed gas stream passes through the air gap and the intense corona converts a percentage of the oxygen to ozone.

...more

Komal Ozone Generator

Ozone system shall include all necessary components and controls to constitute a completely functional and operational generation system intended for 24 hrs. Operation

...more

Perfect Germs Killer

Ultra - violet (uv) rays lie just beyond the visible light band on the shorter wavelength end of the electromagnetic spectrum. The high - energy uv-cray wavelength ranges between 200 nm and 280 nm (nm = 10-9 m). These rays, particularly the 253.7 nm wavelength upon contact (see graph). The destructive uv rays strike and enter the body of germs -bacteria, viruses, yeast, algae and certain protozoa. Once inside, the rays are absorbed by the organism dna this kills it at once it is the simple and swift action that has made uv disinfection the world's most effective and most economical method of obtaining germ - free water for a wide range of end - uses. Uv disinfection is utterly simple-easy to install, easy to operate, and easy to maintain. It takes up very little space, work non-stop over long periods and gives ready-to-user process water instantly.

...more

Chlorine Dosing Systems

One of the best leading supplier of chlorine dosing stems.

...more

softening plants

Strong, Long Lasting KOMAL WATER SOFTENER- engineered for the most demanding industrial, commercial and residential needs

...more

iron Removal Plants

We are leading manufacturer and supplier of Iron Removal Plants

...more

Desalination Plant

We are an eminent and leading trader of Desalination Plant

...more

WFI storage tanks

After the purification of PW or HPW, engineering of the customer-specific storage and distribution system takes place, so product water can be delivered to each point of use in the sterile distribution system without recontamination. Here to we consider the customer's specific conditions and produce an individually Purified water and WFI storage tanks engineered design.

...more

Reverse Osmosis Systems

KOMAL industries is Water Treatment Plant manufacturing company dedicated to offer to our customers the finest commercial, industrial and medical Reverse Osmosis system. We are committed to provide the most innovative, technologically advanced and high quality system. Our knowledge and experience enable us to manufacture most of our parts in-house to ensure system reliability. Our meticulous quality assurance program ensures system reliability and a product that you can depend on.

...more

Tertiary Treatment

One of the suppliers of industrial products, providing various types of products such as Tertiary Treatment

...moreBe first to Rate

Rate ThisOpening Hours