Zero Hold Up Filter Press

We are offering excellence in the form of Zero Hold Up Filter Press to enhance the buyers' content. We have an in-house facility, which is used for making stocks. Laced with modern amenities, our storehouse keeps the products away from moisture, rainwater, sunlight, etc.Details : Sizes available 8”, 14”, 18”, 24” & 33” Diameter MOC SS 316 / 316L. Available models 8”, 14”, 18”, 24” & 33” plate diameter. Available with centrifugal / gear / lobe pump. Fitted with pressure gauge, safety valve & airvent. cGMP with documentation.

...more

Vibro Sifter

Backed by a team of proficient quality inspectors, we provide only quality assured products to the customers. We facilitate trade by providing you varied payment options like payment through online as well as offline modes.Details : High degree of surface finish. Double decker arrangement can be provided. Easy dismantling and cleaning. MOC SS 304 / 316 / 316L. cGMP with documentation.

...more

Single Vessel Ointment Plant

We are a quality-conscious firm and make sure that our offerings are prepared using the world-class raw material and work methods. Also, the material is sourced from the trusted places only. Our packaging materials can retain the products' quality and newness even under extreme shipping and handling conditions. Our packaging provides optimum physical protection.Details : Capacity from 25 kgs. To 1000 kgs. MOC SS 316 /316L. Hydraulic lid lifting for mfg. vessel. Bottom / Top Homogenizer. Fully / Semi automatic operation Dual anchor agitator with fix anchor cGMP with documentation

...more

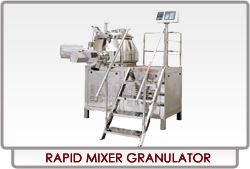

Rapid Mixer Granulator

We are offering excellence in the form of Rapid Mixer Granulator to enhance the buyers' content. In order to meet ever-evolving requirements of the clients, we have installed a capacious storage facility. This unit helps us in keeping stock of products in different grades and specifications.Details : Models available from 3 L to 800 L working capacity. Fully automatic operation based on PLC control. Better productivity & lesser mixing time. Contact parts are SS 316 / 316L. Uniform mixing & granulation. Less handling. More hygienic. cGMP with documentation.

...more

Octagonal Blender

We efficiently cater to the varied demands of the clients and offer them personalized packaging options as well. We ensure that the products are packed sternly using quality packaging material to evade loss. Our payment procedures are well documented, legal, and safe. We provide our clients with numerous online and offline options for making purchases and make sure they are protected.Details : Polygon shaped body. Arrangement of conical adapter & charging drum. High efficiency duplex chain drive. SS pipe railing & guard for safety. Capacity 5 kgs. To 4000 kgs. MOC SS 304 / 316 / 316L. cGMP with documentation.

...more

Multi Mill

With our modern transportation amenities, safe and on-time deliveries are rendered by us! We have adopted modern work methods that aid us completely in maintaining records and give us alerts time-to-time when any products goes short in the shelf.Details : Multi speed drive for various product grinding. Easy dismantling and cleaning. High degree of surface finish. Easy portability. MOC SS 304 / 316 / 316L. cGMP with documentation.

...more

Fluid Bed Dryer

We are backed with highly experience packaging experts and team members; they ensure that the packaging is done with utmost proficiency and keeping in mind the globally accepted norms. We are capable of delivering the orders on time and at any desired Palghar(India) as we are supported by up-to-the-minute facilities.Details : Very versatile process equipment. Fully automatic operation based on PLC control. Minimum handling and more hygienic. Top Mounted telescopic cylinder for auto bag shaking. Clamp type bottom mesh for container. Capacity available from 2.5 kgs. To 500 kgs. MOC SS 304 / 316 / 316L. cGMP with documentation.

...more

distilled water storage tank

We make available, Distilled Water Storage Tank, which is equipped with digital temperature controller/ indicator. This water storage tank has advanced circulation pump for uniform temperature. It is available in the capacities ranging from 100 Ltr. to 10000 Ltr. Details : Available capacity 100 ltrs. To 10000 ltrs. Material of construction SS 316 / 316 Direct heater. Strip heater or steam jacketed / coil. Provided digital temperature controller / indicator. Circulation pump for uniform temperature. Automatic level controller to be connected to MCDP. Horizontal / Vertical execution as per site requirement. All joints nozzles are triclover.

...more

Automatic Ointment Manufacturing Plant

With the aid of modern facility and quality packaging material, we guarantee that the offered lot will reach the destination within a given time frame. We also make sure that the material is sourced from the certified vendors. We are comfortable with traditional payment options as well as the modern ones. Our payment related policies are client friendly. Our payment procedures are transparent, safe, and secure. Application : Pharmaceuticals - Creams, Gels, Sterile & Non Sterile Ointments and Biotech products. Cosmetics - Cold Creams, Hair Dye Cream, Conditioners, Lotions, Gels, Mascara make-up, Shampoo, Toothpaste. Technical feature : Main Vessel : Choice of various type of anchor design. Homogeniser (option) – Top Entry, side Entry, Bottom Entry with circulation facility. Hydraulic lid lifting for fast & easy cleaning of top dish & vessel. Load Cell for fast & accurate measuring system. Flexible product transfer pipe & fitting in case of load cell & hydraulic lifting. VFD for Anchor agitators to vary the RPM. VFD for Homogeniser to vary RPM. Specially Design drive assembly. Wax vessel : Open top with top Entry agitator Cowl disc type or paddle with Slow Speed Anchor. Close top with top/bottom entry agitator Cowl disc type or propeller type stirrer. Water Vessel : Open top with top entry propeller stirrer Close top with bottom or top entry propeller Common Feature : The main function are mixing and emulsifying. This in the broader sense means producing very fine emulsions, suspensions, etc featuring excellent homogeneity and thus finally stability of the mixed product. Jacket have heating & cooling with temperature control with Safety equipment. Electro polished Pipeline and joints are TC standard for easy opening & re-fixing. Vacuum system to transfer product from one vessel to another vessel and zero retention in pre phase vessel & inter connecting pipeline. No Air contamination. / Human contamination. Cleaning In Place cycles with validation protocols. (Optional) Control System : Manual Control – Have temperature indicator /Timer / Single Phase protection /Push Button to operate the complete plant. Auto Control – PLC based with touch screen and pass word level to feed the parameters of process for Heating / Cooling / Stirrer timing/Homogeniser Timing / Stirrer speed / Homogeniser speed / Vacuum / Pressure / CIP etc. This choice of package to suit requirement to each product. Pre stored process parameter will help to achieve consistent product quality. MMI (Touch Screen) for visualization of machines of specific process condition and data PLC Indicates : Visualization of Machine process condition & data. Alarm Signal Fault Message SCADA package (optional) Design Base : A Special pharmaceutical design enables application in biotechnical process. Material, surface as well as general design are in keeping with the GMP directives as well as the recommendations of the FDA & USFDA. Vessel design as per ASME guideline and tailor made design as per user’s / product Requirements. All vessel are per GMP regulations. Total plant is design & supplied as per CGMP guidelines. Advantages : Flexible Configuration Simple Operation Can Be Fully Automated Integration into existing process control system Fast product change over Rapid & effective cleaning CIP/SIP Homogenous product consistency without trapped air bubbles. Mixing, dispersing and homogenizing in one operation Capacity - 5 Kg to 3000 Kgs

...more

Automatic Liquid Process Plant

As, our organization has stringent quality management strategies, our complete range of products is preferred by many across the industry. Clients can select any payment mode from our online or offline methods. Both of them are secure, hassle free, and ensure the fastest trade with the customers.Details : MOC SS 304 / 316 / 316L. We can Manufacture as per customer design / requirement. Electric heating also possible for smaller capacity. Top mounting stirrer / homogenizer also available. PLC based Fully automatic plant also available. cGMP with documentation

...more

Tube Filling Machine

Due to the capacious and well-maintained storage unit, we keep a large stock in a safe place to ensure complete safety. This unit also helps us in maintaining high quality standards. With our modern transportation amenities, safe and on-time deliveries are rendered by us! Features:• Automatic Tube Loading System.• Auto Tube Orientation.• No Tube No Fill System.• Folding & Coading at Individual Station.• Simple Mechanism & Operator Friendly Machine.• Combo Model Suitable For Both Aluminium and LamiPlastic Tubes.• Out Put 70 to 80 Tubes Min - For Double Head Mc.• Out Put 35 to 40 Tubes Min – For Single Head Mc.Technical Specification:• Filling Range 3 Gm To 250 Gm With Change Over.• Tube Dia Upto 25 mm - For Double Head.• Tube Dia Upto 45 mm - For Single Head.Power Consumption:• Max. Kw – 5• Air Consumption 15CFM @ 6 Kgcm2• Chilled Water Consumption LPM @ 10°c

...more